Water treatment technology

GT Media from ADI International has been used to successfully remove arsenic concentrations up to 700 ppb, providing consistent reductions to less than 3 ppb. The media is used in a treatment system that consists of a pressure vessel containing the media. Water passes downward through the filter. The media adsorbs arsenic, lead, copper, uranium, and other metals. It performs well over a pH range of 5.5 - 8.0 and is unaffected by high concentrations of contaminants such as sulfates or chlorides. Pressure drop through the filter is typically less than 2 psi. When the media becomes saturated with arsenic (depending on inlet arsenic concentration this can take several months to over a year), it can be regenerated in-place with a process that takes less than two hours. The spent regenerant, after pH adjustment, is suitable for sewering or non-hazardous landfill disposal. Due to its simplicity and low cost, the system is suitable for remote areas where budgets are tight and specialized water treatment personnel are often unavailable.

ADI International

Fredericton, NB, Canada

Tel: 506- 452-9000

Fax: 506- 451-7451

Web: www.adi.ca

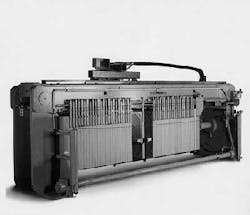

Self-cleaning filters

Amiad Filtration offers a line of filtration products with inlet/outlet sizes from 3/4 inch to 24 inches and filtration degrees from 10 to 5000 microns. The filters are available with body materials of plastic, polyester-coated carbon steel and stainless steel. Depending on the filtration needs, media solutions include 316L stainless steel elements, polyester disk elements and variations of bed media. The self-cleaning filtration systems can be designed for virtually any flow rate. They can be used to replace settling ponds for drinking water influent, providing a balanced load of suspended solids to the plant.

Amiad Filtration Systems

Ventura, CA

Tel: 800-969-4055

Fax: 800-988-3313

Web: www.amiadusa.com

DE filtration book

The American Society of Civil Engineers has published a book on diatomaceous earth (DE) filtration as applied to the treatment of drinking water. The book provides engineering professionals with all the information needed for evaluating DE filtration as an alternative method of treatment that is both cost effective and small in installed size. The book serves as a reference and as a practical design manual, providing both background performance data and tips for applications ranging from conventional to unusual treatment situations.

ASCE

Reston, VA

Tel: 800-548-2723

Fax: 703-295-6339

Web: www.pubs.asce.org

Automatic filtration

Valve & Filter Corp. offers automatic water filters for flow rates to 8000 gpm and up. The filters are U.S. manufactured to ASME pressure vessel specifications. Typical applications are in water and wastewater treatment, including media prefiltration and tertiary flow. The filter is self-cleaning with no bags, elements, or cartridges to change. Filters are complete with AC or battery controllers. Custom materials, configurations and complete systems are available.

Valve & Filter Corp.

Tel: 800-759-6554

Web: valveandfilter.com

Membrane Filter Press

Rittershaus and Blecher Membrane Filter Systems, offered by Baker Process, add new dimensions to the operability and performance of the proven chamber filter press technology. They feature shorter cycle times, with increased capacity for existing filter presses or lower investment for new facilities. They also produce drier cake solids, for lower transport and disposal costs for landfill or lower thermal energy costs when drying or incinerating sludge product. The systems have a reduced need for conditioning chemicals, so specific cake solids objectives are possible with significantly lower conditioning chemical requirements.

Baker Process

South Walpole, MA

Tel: 508-668-0400

Fax: 508-668-6855

E-mail: [email protected]

Sample preparation

A new sample preparation system for on-line monitors is being introduced by Bran + Luebbe. The CeraClean Filtration Unit removes solids, colloids and high molecular weight compounds from water and wastewater, and provides a continuous supply of clean filtrate for on-line monitors. The system is particularly effective in grease removal, sludge treatment, and soil leachate monitoring stations. It features an automatic backflush system that more than doubles the interval between cleaning. Energy costs are also reduced by 50 percent.

Bran + Luebbe

Buffalo Grove, IL

Tel: 847-520-0700

Web: www.branluebbe.com

Underdrain systems

F.B. Leopold produces the Type S and Type SL Underdrain for water filtration. The Type S features a unique water recovery channel for improved air water backwash performance. The channel is located in the top of the underdrain block and works to increase the airflow range, improve air stability and prevent lower water maldistribution. The Type SL delivers the same performance, but is 4 in. lower for shallower filters or where grater media depth is required. The underdrains are constructed of HDPE for strength, light weight, and corrosion resistance. They have smooth surfaces, which reduces calcification.

F.B. Leopold Co. Inc.

Zelienople, PA

Tel: 724-452-6300

Fax: 724-452-1377

Web: www.fbleopold.com

Self-cleaning filters

Filtomat, Inc. has introduced the M100 Series family of Automatic Self-Cleaning Water Filters suitable for use on wastewater effluent and other water. The filters are designed to filter out particle sizes from 15-3,000 microns and rinse hydraulically without any interruption in flow. The filters use a flushing mechanism that "vacuum cleans" the screen effectively removing particles and stubborn organic and inorganic material from the screen. They are available with inlet/outlet sizes from 2 in. to 10 in. and a maximum flow rate up to 1,760 gpm per single unit.

Filtomat, Inc.

Closter, NJ

Tel: 201-784-7752

Fax: 201-784-7758

Treatment system

Filtronics offers a system designed to remove odors and color from drinking water. The water is treated with chlorine and alum to produce non-detectable color units and no taste or odor from hydrogen sulfide in the filtered water. The system includes an automatic filtration system that removes material smaller than two microns, including giardia and cryptosporidium. Typical filtration runs are 18 to 20 hours. The one-minute surface wash and four-minute backwash automatically occur on shutdown or on a call from the differential pressure override. The unit produces a finished water turbidity of 0.07 NTU.

Filtronics, Inc.

Anaheim, CA

Tel: 714-630-5040

Fax: 714-630-1160

Web: www.filtronics.com

Membrane filtration

Filmtec® reverse osmosis and nanofiltration membranes from Dow chemical are based on proven, spiral-wound, thin-film composite, polyamide membrane technology. They consist of three layers: an ultra-thin polyamide barrier layer, a microporous polysulfone interlayer, and a polyester support web. The underlying structural support is provided by the non-woven web. The polyamide barrier layer provides high water flux, salt and silica rejection and chemical resistance. Nanofiltration elements remove particles in the 0.001 micron range; RO elements remove particles down to 0.0001 micron and smaller.

Dow Chemical Co.

Midland, MI

Tel: 517-636-9086

Web: www.dow.com

Bag filters

The Loeffler Flowline bag filter from Hayward Industrial Products features a specially designed cover that can be oriented in the field to open and close in any of four different directions with the use of ordinary hand tools. This feature reduces installation costs because piping system layout does not have to be changed. The bag filters are available with either threaded or flanged piping connections in sizes for single or double length filter bags. Hundreds of different size filter bags are available in dozens of different materials and in micron ratings from 1/2 to 1200.

Hayward Industrial Products

Elizabeth, NJ

Tel: 908-351-5400

Fax: 908-351-7893

Web: www.haywardindustrial.com

Ceramic filtration media

Macrolite, a development by 3M Co. and Kinetico Inc., is a ceramic filtration media that is an alternative to membrane filtration. The spherical shaped and variable sized media can be used to filter drinking water to meet enhanced SWTR regulations. The ceramic media does not typically ever need to be replaced. A newly developed CD ROM highlights the benefits and characteristics of the media.

Kinetico Inc.

Newbury, OH

Tel: 800-432-1166

Fax: 440-564-7696

Web: www.kinetico.com

DE filters

Diatomaceous Earth (DE) filtration systems from Mer-Made are designed for use on applications with flow rates from less than 50 gpm to 10 mgd. Raw water is drawn through the filter leaves via pump suction and sent directly to system storage. No pre-treatment is required. The company's package system provides the required square footage of filter leaves in a fiberglass tank. An integral fiberglass shelf supports the main filter pump and a recycle pump. The recycle mode is used to maintain filter cake when storage is full. A level control system is also built in.

Mer-Made Filter

Denmark, SC

Tel: 803-793-4265

Fax: 803-793-4332

Web: www.mermade.com

Overhead filter presses

Netzsch has introduced a new generation of Overhead Filter Presses that allow free access to the plate pack. The presses feature an overhead rotating bearing assembly for self alignment. They also feature plate shifters outside of the potential spill areas and optional automatic cloth washers. In corrosive environments, stainless steel cladding can be added. The presses are available in five sizes to 2000 x 2000 meters, with operating pressure up to 450 psi.

Netzsch Inc.

Exton, PA

Tel: 610-363-8010

Fax: 610-363-0971

E-mail: [email protected]

DE filter

GNT Filter Co. offers a new water filter for small community and municipal water treatment systems. Designed around the EPA approved method of using diatomaceous earth filter media, the filters achieve consistent turbidity removal to under 0.2 ntu. The horizontal filter plates allow routine filtration starts and stops. Cleaning involves removal of dry cake and does not require backwash discharge. The skid-mounted 5-25 gpm systems offer easy installation and can operate unattended.

GNT Filter Co.

Fairfield, CA 94533

Tel: 707-426-0926

Fax: 707-427-3072

Filter media

Northern Gravel supplies filter media that meets or exceeds the standards of consulting engineers and those recommended by the American Water Works Association. The company's products are NSF listed. From single bag orders to multiple carloads, Northern Gravel meets specific needs with tolerances from .25 mm to 2.5 mm. The company's sand is hard, not smooth, and free of soluble particles. To assure chemical quality, the company uses the most modern equipment for washing, drying, screening, and testing.

Northern Gravel Company

Muscatine, IA

Tel: 319-263-2711

Fax: 319-263-2857

Web: www.northerngravel.com

Mesh netting

NSW Corp offers precision mesh net made from DuPont® Hytrel® thermoplastic elastomer. This distinctly bi-planer extruded netting features temperature and chemical resistance as well as resistance to creep, impact and flex fatigue. It is available in a 0.052 in. thick flat sheet and roll widths up to 20 inches. Available colors are black and natural.

NSW Corp.

Roanoke, VA

Tel: 800-368-3610

Fax: 540-345-6793

Web: www.nswcorp.com

Filter nozzles, strainers

Orthos Liquid Systems specializes in providing filter nozzles and strainers for filter underdrain systems. The company offers a variety of nozzle styles, slot sizes, air scour tubes and flow characteristics for several filter underdrain and filter bottoms including false plate, pipe header/lateral, and monolithic/concrete underdrains. Material of construction includes polypropylene, glass fiber reinforced polypropylene, Kynar and stainless steel. The company also specializes in retrofitting existing filters and replacing and upgrading nozzles.

Orthos Liquid Systems

Bluffton, SC

Tel: 843-987-7200

Fax: 843-987-7203

Web: www.orthosnozzles.com

Filtration

Osmonics has released an enhanced version of its copyrighted publication "Filtration Spectrum." The revised version shows the relationship among filtration and separation pore size and fluid contaminants removed, and also illustrates which Osmonics® filtration and separation products are effective for the objectives described. The document discusses the five classes of filtration and separation: reverse osmosis, nanofiltration, ultrafiltration, microfiltration, and particle filtration. The spectrum graphs each filtration class and states the micrometers, angstrom units and molecular weight of materials suitable for separation in each class.

Osmonics

Minnetonka, MN

Tel: 952-933-2277

Web: www.osmonics.com

Bag filter housing

Rosedale Products has introduced an all plastic Model 8 generation two bag filter housing. The improved, one-piece design allows flows to 100 gpm while offering excellent corrosion resistance. The covers are easy to remove and built-in basket handles allow for fast bag change-out. Filter bags are available in a variety of micron ratings.

Rosedale Products

Ann Arbor, MI

Tel: 734-665-8201

Fax: 734-665-2214

Web: www.filterzone.com

Column filtration system

The Phipps & Bird Column Filtration System (CFS) simulates the process of a direct-filtration water treatment plant. It is an accessory to the traditional Phipps & Bird JarTester. The device consists of four or six filter columns (2" ID clear PVC); a series of valves for controlling the flow of water from the sample beakers or for use in the backwashing process; and a castered rack. The CFD can be used in the lab or rolled to a more convenient location within the treatment plant. After water samples are agitated through the flash and flocculation stages they are allowed to gravity drain through the filter columns, producing a simulated "clean" water sample. A water line from the plant's service line can be connected to the unit to backwash the filter columns when loading the granular media or when cleaning the media following a test procedure.

Phipps & Bird, Inc.

Richmond, VA

Tel: 800-955-7621

Fax: 804-254-2955

Web: www.phippsbird.com

Filter polishing

The DynaSand Filter from Parkson can handle high-feed suspended solids and yield effluent quality to meet or exceed regulations, with an overall pressure drop less than three feet and minimal energy use. The filter's continuous-backwash design eliminates the need for a backup system and its associated downtime. Filter design is deep-bed, top-feed, using uniform granular media and no moving parts. Modular system designs in concrete or stainless steel allow for flow capacities of any size.

Parkson Corporation

Fort Lauderdale, FL

Tel: 954-974-6610

Fax: 954-974-6182

Web: www.parkson.com

Microfiltration system

Aria Membrane Microfiltration systems are designed for drinking water filtration in municipalities with populations of 10,000 or less. The systems are skid-mounted, fully automated and self-contained to facilitate installation. Once programmed, the system will run unattended at a constant clean water production rate. The systems use Pall Microza Drinking water Microfiltration modules to provide drinking water purified to levels exceeding EPA's Surface Water Treatment Rule. The system is capable of removing iron and manganese from groundwater sources, and turbidity, organics, color, pathogenic cysts, oocysts and viruses from surface waters. The hollow fiber membranes also are resistant to chlorine, ozone and permanganate.

Pall Corporation

East Hills, NY

Tel: 516-484-4400

Web: www.pall.com

Filter press

Star Systems Filtration has introduced a new line of lightweight filter presses specifically designed to dewater wastewater sludges. The Star PolyPresses feature standard CGR polypropylene plates and inlet pipes, Schedule 80 PVC air blowdown manifolds and heavy-duty carbon steel stands with epoxy coating. Available options include feed pumps, automatic pump controls, plate shifters, cake discharge systems and precoat/body feed systems.

Star Systems Filtration

Timmonsville, CS

Tel: 800-845-5381

Fax: 843-346-3736

Web: www.hilliardcorp.com

Immersed Membrane Technology

Zenon Environmental manufactures membrane-based technologies for water purification. Its ZeeWeed® is an immersed hollow-fiber membrane technology that uses a low pressure suction to draw water through the pores of the membrane. Because the system uses immersed membranes, it can be combined with coagulants to remove color and total organic carbon from most waters. Zenon also has patented an ultrafiltration enhanced coagulation process that produces high quality drinking water from colored water sources.

Zenon Environmental, Inc.

Oakville, ON, Canada

Tel: 905-465-3030

Fax: 905-465-3050

Web: www.zenonenv.com

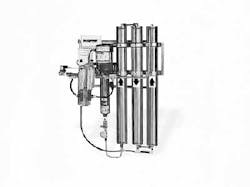

Wall mounted RO system

Wall mounted Reverse Osmosis systems from Ecodyne are available in 14 different models with a standard stainless steel frame. Capacities range from 650 to 5,600 gallons per day. Each model features low-energy TFC membranes. Multi-stage centrifugal pumps with plastic impellers are available on systems above 1800 gpd. All RO systems use the latest technology and materials available for removal of particulates and dissolved solids from water.

Ecodyne Water Treatment

Naperville, IL

Tel: 630-961-5043

Fax: 630-961-5174

E-mail: [email protected]

Backwash system

Tonka's Simul-Wash is a water conserving, sustained simultaneous air and water backwash system. The system uses the AWWA research-supported "collapse-pulsing" action. The low profile system works in pressure, gravity and greensand filters. It is suited for retrofitting existing filters without affecting plant hydraulics or requiring unnecessary underdrain replacement.

Tonka Equipment Co.

Plymouth, MN

Tel: 612-559-2837

Web: www.tonkawater.com

Gravity filters

CenTROL® filters, part of the General Filter product line of USFilter, are conventional gravity filters in a cluster arrangement that can reduce installation and operating costs. A single control column normally serves four cells, and all four cells can be observed and controlled from the central operating platform. The stainless steel center control column is the key to the design. It is a pre-fabricated structure with shop-tested filter function valves. This feature eliminates the need for on-site installation and fabrication of a piping gallery. Another advantage of the system is the ability to backwash filter cells with water from the other in-service cells, eliminating backwash supply pumps. A single filter can treat up to 15 mgd of drinking water, and multiple units have been used in high-volume applications.

US Filter

Sturbridge, MA

Tel: 508-347-7049

Web: www.water.usfilter.com

Ultrafiltration

Smith & Loveless' Innovative Membrane Filtration (IMF) Protector system surpasses strict potable water standards. The system features low-foul KALMEM membranes that provide a barrier to fine particles, including waterborne pathogens such as cryptosporidia and giardia. The system achieves removal efficiencies of 5-log for cryptosporidia. The unit's direct flow design is more efficient than traditional cross-flow or tangential-flow because a greater percentage of the feed water permeates through the hydrophilic membranes and the setup eliminates the need for recirculation and associated pumping. The unit backwashes the hollow-fiber membranes by pulsing filtrate through the element's exterior surface.

Smith & Loveless, Inc.

Lenexa, KS

Activated carbon system

NORIT Americas offers systems for the addition of powdered activated carbon (PAC) to a water process stream. The company's Porta-Pac dosing system is designed to allow bulk silos or bulk bags of PAC to be used for wet injection into water filtration systems. The company designed the system to provide reliability, accuracy of dosing, and cleanliness. NORIT produces raw carbon materials and the company's technical specialists analyze treatment requirements to match the best type of activated carbon to the application.

NORIT Americas Inc.

Atlanta, GA

Tel: 770-512-4610

Fax: 770-512-4622

Web: www.norit-americas.com

Filter package plant

The John Meunier Products Division of USFilter offers the Actiflo® clarification system and filter package plants as a unit engineered to provide a compact, modular system for drinking water or wastewater treatment. The plants comes with all necessary monitoring equipment, including a control panel. Field instrumentation such as a turbidimeter, a pH-meter, a chlorine analyzer and a remote monitoring system can complete the package as options. The plants are delivered pre-assembled. Multiple units may be installed in parallel.

John Meunier Division, USFilter

Saint-Laurent, Quebec

Tel: 514-334-7230

Fax: 514-334-5070

Web: www.johnmeunier.com

Ultrafiltration literature

USFilter's Industrial Wastewater Systems group has published a new technical brochure, "Ultrafiltration Systems for Wastewater Treatment." The six-page brochure features three types of ultrafiltration systems: ceramic multi-channel elements, spiral-wound polymeric, or tubular polymeric membrane configurations. Membrane modules may be selected based on the characteristics and condition of the feed solution. Typical applications include reverse osmosis pretreatment.

USFilter Industrial Wastewater Systems

Warrendale, PA

Tel: 724-772-1258

Fax: 724-772-1202

Web: www.usfilter.com

Underdrain system

The SCUBA water and wastewater filter bed underdrain system from USFilter is designed for efficient retrofits and plant expansions, supporting dual or mixed media without a gravel layer. Providing the option to support mixed media beds allows filters to run at up to 30% higher flow rates, increasing plant capacity without installing additional filters. Upgrading to a SCUBA with a Multiwash baffle system allows existing plants to also increase filter backwash and cleaning efficiency. The two processes together allow for continuous combined air/water backwash. This type of backwash provides a vigorous scouring action, returning a clean filter bed without media loss.

USFilter Water Process

Sturbridge, MA

Tel: 508-347-7049

Web: www.water.usfilter.com