Butler Water Treatment Plant Solves Membrane Integrity Issues

Butler Water Treatment Plant (WTP), located in Missouri, receives its influent from a surface water impoundment fed from Butler Lake, Marais des Cygnes River, and Miami Creek. Following treatment, it provides potable water to over 300 businesses, four schools, 4,100 residents, and four other Public Water Supply districts.

Butler WTP was originally constructed in 1967 with a 1 MGD capacity and utilized upflow clarifiers, dual-media filters, and a disinfection tank. The plant operated successfully with this flow scheme until 2002 when its dual-media filters were in desperate need of replacement in order to meet state effluent permit requirements.

The city decided to replace the dual-media filters with low pressure, hollow-fiber ultrafiltration (UF) membranes to resolve the issue. The system had a 2 MGD capacity and consisted of four disk-type 100-micron strainers, four membrane trains - each with 27 modules, two backwash pumps and one clean-in-place (CIP) chemical cleaning system. Not long after startup, the membranes failed periodic air integrity tests (AIT) given to detect fiber breaks or other integrity failures. Eventually, none of the four UF trains could pass an AIT without multiple fiber repairs. This was costly and the plant was struggling once again to meet its water demands in 2012.

To combat the integrity failures quickly, the city decided to replace membrane modules in three of the four trains with membranes from the same manufacturer. The supplier’s newer, more-robust membranes would not retrofit easily into the existing module racks, requiring costly skid modifications, so they decided to stay with the original model. These membranes, like the ones before them, began to fail the AITs shortly after startup. At the same time, the plant was informed that the Environmental Protection Agency’s Long Term 2 (LT2) Enhanced Surface Water Treatment Rule would go into effect in October 2014. This rule would demand automatic, daily AITs. Knowing that the existing membranes would not meet the new stringent requirements or pass daily testing, a different alternative needed to be explored.

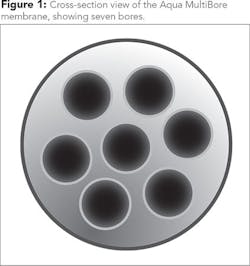

In April 2014, Butler decided to conduct a 9-month pilot study with 21 Aqua MultiBore® membrane modules retrofitted into Train 2. Train 2 was tested alongside the other three UF trains and proved the superior performance of the MultiBore membranes. The city finally found a solution and would retrofit the other trains in 2014 and 2015.

Membrane Process

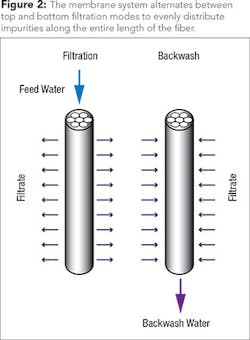

The membrane system alternates between top and bottom filtration modes to evenly distribute impurities along the entire length of the fiber. The 0.02 μm pores allow water to pass through to the outside of the fiber while suspended solids, bacteria, cysts, and viruses are retained. Filtered water flows through the filtrate port on the side of the module.

The system also alternates between top and bottom backwash modes so impurities can be efficiently flushed out. Filtered water enters the filtrate port, flows into each fiber, then exits out to the drain. Backwash occurs every 20-80 minutes, depending on influent quality.

A CIP mode is performed periodically to dissolve any remaining impurities not removed during backwash modes. Small amounts of chlorine (for organic matter) and citric acid (for inorganic matter) are used. The membranes are soaked before being flushed out. CIP is executed every 2-6 weeks, depending on influent quality.

Butler’s existing four-train system was retrofitted with 84 MultiBore membrane modules (replacing 108 old modules) with a design capacity of 2 MGD. Effluent values would meet the EPA LT2 rule of ≥ 99.99 percent (4-log) cryptosporidium removal and ≤ 0.1 turbidity in order to discharge potable water.

The Aqua MultiBore membranes have outperformed the existing membranes by removing 13-36 percent more turbidity at a 24-33 percent higher permeability (specific flux). In addition, the membranes pass continuous indirect and daily direct air integrity testing to consistently meet the stringent permit requirements. The ability to retrofit into the old membrane module racks reduced the plant’s upgrade cost and minimized system modifications.

Aqua-Aerobic Systems Inc. is a leader in the design and manufacture of wastewater treatment equipment and systems for both municipal and industrial markets worldwide. To learn more, visit www.aqua-aerobic.com.