Air Scouring – An Alternative For Water Main Cleaning

By Robert Grob

Eliminating sediment and debris from municipal water mains that deliver potable water to residences and businesses can help preserve water quality, increase flow and pressure – and maintain a municipality's good reputation.

Consumers are often the first to notice the need to clean water mains by observing discolored water or experiencing reduced pressure. Producers of potable water may also discover sections of their distribution systems where disinfecting residuals are difficult to maintain. Biofilm buildup is often the cause. When discolored water, reduced pressure, or poor disinfection control is experienced, the need to clean the mains is evident.

Municipalities typically use one of two options to clean water mains: flushing the main with large quantities of clean water through unidirectional flushing (UDF), or physically passing a "pig" or "swab" through the main.

Air Scouring, a patented method of water line cleaning available from Severn Trent, can be a more cost-effective solution – generally, about one third the cost of pigging or swabbing. By isolating a section of the water main between an entry point and exit point — typically fire hydrants — the section is purged of standing water with high-volume, high-velocity and low-pressure air. Slugs of water are then produced when the valve upstream of the entry point is opened slightly, allowing the passage of controlled amounts of water into the section. The compressed air, mixing with the water slugs, creates a vortex that travels through the isolated section removing sediment, biofilm and soft mineral scale. When water exiting the line is clear, service is restored to the section.

The primary benefit of Air Scouring is the removal of sediment, thus improving water quality. But often, flow capacity also can be increased.

Hazen-Williams

Prior to Air Scouring, loss-of-head tests may be performed using the Hazen-Williams "C" value test, an empirical formula used extensively in the United States in the design of water supply systems. The test determines the coefficient "C" that represents the internal friction of the pipe. As water flows through a pipe, head losses (i.e., pressure losses) occur due to friction. The amount of head loss will vary depending on the diameter of the pipe, the rate of flow and the roughness of the pipe wall.

The roughness coefficient is a function of the condition of the inside of the pipe. Values range from 140 for very smooth pipe, down to 80 or less for old, unlined and tuberculated pipe.

Case Study

Like the water main systems of many municipalities in the East and Midwest, the age of portions of the system in the Village of Ripley, OH, caused occasional flow capacity and water quality problems. With sections of the system more than 100 years old, the roughness of the inside of the pipes slowed the flow of water and contributed to water quality issues.

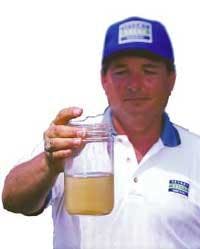

The village's water comes from a groundwater source containing manganese, which would slowly precipitate out in a black sediment. During times of peak loading – such as when the fire department was fighting a fire – sediment in the distribution system would be disturbed and appear at points-of-use. This is not an uncommon situation, particularly in older water main systems. The water quality was in compliance with local regulations. But a municipality's reputation is built on more than just "meeting code." So the village decided to investigate options for cleaning the water main system as an alternative to replacing entire sections of the system.

An initial Hazen-Williams "C" test prior to cleaning showed a coefficient of 67 for the chosen section of 8'' pipe. During the Air Scouring procedure a scouring velocity of approximately 20 feet per second was achieved – far greater than typical flushing velocities (The key to Air Scouring is the high velocity of the water used to clear the pipe, not higher pressure.) The scouring process removed manganese build-up along with other loose tuberculation inside the pipe throughout the 15,000 feet of water main.

Immediately following the procedure, a second head loss test was performed. The Hazen-Williams value was 96 – a significant improvement.

About the author:

Robert Grob is Business Development Manager, Pipeline Services, at Severn Trent Services.

Depending on site-specific details, municipalities can realize one or more of the following benefits through Air Scouring:

• Eliminates the need for temporary ground piping to provide service water, reducing costs.

• Provides cleaner mains allowing better flow, reducing pumping costs, eliminating discolored water, and improving disinfection control.

• Uses less water than Unidirectional Flushing.

• Cleans all wetted parts of each valve, allowing for ease of future operation.

• Requires operation of valves and curb stops, helping to identify poorly functioning components so that they may be scheduled for repair or replacement.