The Simul-Wash� system incorporates a baffled trough that is a low profile design allowing installation into shallow filters. The media-retaining design assures less than 1" per year media loss under collapse-pulsing backwash conditions.

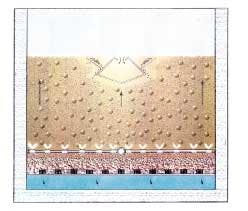

Click here to enlarge imageJust prior to collapsing, high local water velocities occur at the perimeter of the bubble. Simultaneous to bubble collapse, media particles rush together and collide in a violent scouring action. This creates a "pulsation" in the bed. The bubble travels on upward, expands, collapses and re-forms again, and repeats the process several times as it passes through the bed. Eventually the bubble reaches the surface and bursts to atmosphere. This collapse-pulsing action was verified using endoscopic video cameras during the latter stages of the research, and appears as a violent pulsation throughout the depth of the media.

Filter Geometry

The only limitation of the AWWARF research was that the time of the backwash was assumed to be limited by filter geometry. Most existing rapid sand gravity filters are designed for water only backwash with maximum 50% allowable room for media expansion below the backwash troughs. This means that to practice simultaneous air and water backwash, water needs to be drained down to 6'' above the surface of the media, air scour applied, and then water introduced simultaneously until the water surface rises to the bottom of the backwash trough. At this point the air must be turned off and water only backwash must commence. If the air is not turned off, media loss will occur. Collapse-pulsing action is so violent that it expands media all the way to the water surface.

Sustained Simultaneous Air/Water Backwash

In the late 1970s research was begun on baffled backwash trough technology suitable for sustained simultaneous air and water backwash. That research led to the development of the baffled trough design offered by Tonka.

The Simul-Wash™ system incorporates a baffled trough that is a low profile design allowing installation into shallow filters. The media-retaining design assures less than 1'' per year media loss under collapse-pulsing backwash conditions.

The trough is fabricated from stainless steel, providing corrosion resistance. Added characteristics of the system include a high moment of inertia for the baffled trough, with the ability to span approximately 23' without requiring intermediate support. This is a key advantage in retrofitting large shallow filter cells with the system..Conclusions

Typical backwash rates include 3 to 5 GPM/sq.ft. of water with air at 2 to 3 SCFM/sq.ft. applied simultaneously. This sub-fluidized water flow rate reduces backwash volume by up to 50% versus conventional backwash systems. Because a re-stratification step is required, a dual rate or variable rate backwash control must be furnished. PLC controls are required to ensure that each filter is backwashed exactly the same way each time backwash is initiated. Maximum water conservation is only attainable when collapse-pulsing action can be sustained.

The Tonka technology also has been incorporated in new pressure filters, and it includes all necessary features of a properly designed sustained simultaneous air/water backwash system for potable water applications.

About the Author:

Thomas D. Davis is President of Tonka Equipment Co., Plymouth, MN. He has over 25 years of professional experience in the potable water treatment industry. A registered professional engineer, Davis holds membership in the American Society of Civil Engineers; the American Waterworks Association; and the Water Environment Federation. For more information, contact Davis via e-mail at [email protected].