RO System Tackles Brackish Water from Aquifer

By Mike Liggins

Bonita Springs, FL, sits on the state's west coast, where the western edge of the Everglades meets the Gulf of Mexico. This proximity to the Everglades; a rapidly growing population with its accompanying demand for water; and competing uses for the limited fresh water supply forced Bonita Springs Utilities Inc. (BSU), a not-for-profit, member-owned utility, to make a change in its water treatment technology.

Population in the Bonita Springs area has grown from 30,000 in 1995 to a 2000 level of 47,000, with a projected 2005 level of 65,000. With this growth in population comes a growth in water demand, from 4.2 mgd in 1995 to 7 mgd in 2000 and 12.6 mgd projected for 2005. Satisfying this demand requires an alternative water source to supplement existing well fields in the more surficial freshwater Tamiami Aquifer.

The South Florida Water Management District's (SFWMD) Lower West Coast Water Supply Plan, part of its efforts to restore water levels in the Everglades, is emphasizing that municipalities switch to brackish water supplies rather than expand freshwater well fields. In its desire to comply with this guideline, Bonita Springs elected to meet all growth in water usage needs with water from the Upper Floridan aquifer system.

This aquifer is an 800 ft. deep source that does not impact the Everglades. This new source has different characteristics than the existing more surficial freshwater aquifer; increased saline level is the most notable of these. The more conventional lime softening method in the existing water treatment plant was not capable of treating this brackish water source, and the utility turned to reverse osmosis (RO) technology.

BSU serves an area of about 60 square miles, containing approximately 20,000 homes and businesses. The existing water treatment plant provides lime softening treatment for a maximum of 8 mgd and remains in operation. The new RO plant was designed for an additional capacity of 12 mgd. Phase one implemented the installation of equipment for half of that capacity. The new plant is served by a field of eight wells drawing from the deeper Floridan aquifer.

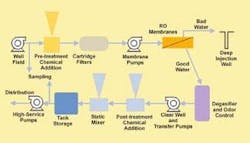

Raw water is sampled and tested, with chemicals being injected as needed to change pH and salt solubility. This protects the RO membranes from crystallization. Cartridge filters then remove suspended solids, such as sand.

After this pretreatment stage, water goes to the separation stage. Here the RO technology uses a combination of pressure differentials and semi permeable membranes to extract good water from the salty water. The membranes, provided by GE Osmonics, are configured in a 24/12 arrangement for each skid, and the system uses four skids to achieve the 6 mgd capacity. The input pressure is 230 psi. The good water exiting the membranes is at 15 psi, and the system has achieved a recovery rate of about 80 percent.

The good water then goes to a degasifer and odor scrubber, which removes and treats hydrogen sulfide from the water, before sending it to a clear well holding tank and transfer pumps. Next is the addition of post treatment chemicals, such as chlorine, that make the water ready for distribution. BSU's distribution system consists of 330 miles of transmission and distribution piping, plus 10 million gallons of above-ground tank storage.

The salt water rejected from the RO process is sent to a deep injection well 3,200 feet below ground to a depth where native water is saltier than the RO reject water. The well is covered by multiple aquacludes (layers of clay) to prevent upward migration of the salt water. Monitoring wells at a depth of 1700 feet test for changes and assure that no impact from the deep injection is taking place.

RO is the heart of the plant, but the brain is the automation and control system, provided by systems integrator Revere Control Systems of Birmingham, AL. The control system is extensive. A well master communicates with seven wells; a membrane train master controls four membrane trains, three chemical feed systems, a degasifier and odor control system, a storm water pump station, and an injection and monitoring well system; and a high-service pump master controls the high-service pump drives. Allen-Bradley PLCs are used exclusively in the system.

All three master programmable logic controllers (PLCs) communicate to the new control room via a fiber optic Ethernet network. In all, more than 55,000 feet of fiber optic cable are used throughout the plant to network the complete control system. Personal computers in the control room provide the operator positions, from which the entire plant is monitored and controlled. From these locations, all of BSU's water and wastewater plants can be monitored.

About the Author:

Mike Liggins is staff engineer for Bonita Springs Utilities, Inc. Brought on board to oversee plant construction, he started in May 2002 during groundbreaking of the RO plant. Currently, Liggins is overseeing the design and construction of the utilities' second wastewater plant. Prior to joining the utility, he worked in private consulting on a variety of projects including general site development and utility expansions.