Process Automation Enhances BNR in Aerated-Anoxic Systems

By John Sheridan

Effective process control automation for biological treatment systems must control aeration, solids inventory and process configuration simultaneously. This is especially true with biological nutrient removal (BNR) to very low levels.

The majority of new NPDES permits require biological nutrient removal, including total nitrogen and/or phosphorus removal. While the BNR process can reliably remove both nitrogen and phosphorus, it requires precise control of reactor conditions. Effective automation can help reduce operating costs (power and labor) while increasing reliability.

USFilter Envirex Products combines oxidation-reduction potential (ORP) and dissolved oxygen (DO) control to optimize oxygen delivery to aerated-anoxic reactors in BNR applications. Compared to conventional BNR methods, ORP control using an aerated-anoxic reactor system is a more efficient and more reliable means of removing phosphorus and reducing nitrogen to very low levels. Control systems that pair ORP with DO can produce higher quality effluent and reduce operating costs. This is especially true for multi-stage aeration systems that use aerated-anoxic reactors for simultaneous BNR.

USFilter's SmartBNR™ process control system optimizes oxygen delivery to a process using aerated-anoxic reactors. It also maintains precise reactor conditions to remove both nitrogen and phosphorus, and provides selection of microorganisms to minimize the chance of bulking and other process problems.

To develop the system, USFilter's process engineers studied reactor conditions using ORP and DO trends that signal process changes and potential degradation before it occurs. The result: a responsive system that predicts reactor behavior and changes conditions in advance.

The principle features of the process control system are:

• Precise control of simultaneous nutrient removal in the aerated-anoxic reactor;

• Predictive aerator response to reactor conditions and oxygen demand;

• Integrated control strategy using both ORP and DO in reactors in series;

• Automated sludge wasting to control to an optimum sludge age; and

• Automated response to stormflow conditions.

The system's automated SRT controls and stormflow modes allow for hands-free operation. The SRT control system measures the solids inventory in the process and wastes sludge to maintain a constant target sludge age while the stormflow mode automatically ensures solids do not wash out of the plant during a heavy rainstorm. Such automated features spare operators from having to be onsite or available 24/7. The system performs control functions, even without constant supervision.

The SmartBNR™ process control system can operate simultaneously an unlimited variety of plant control functions. For example, in a plant with an equalization basin, the controller can measure the basin's level and adjust pump speed to meet process goals.

The system can be retrofitted into existing plants, ranging from use of PLCs and equipment compatible with existing automation to simplified human/machine interface (HMI) for plants with little or no automation. The system uses a panel PC running specialized software for the HMI. The software automatically shares all graphics and control points with the same brand of SCADA software, reducing the cost of the SCADA system. The SmartBNR™ system is also capable of communicating with other standard SCADA systems.

The process control system is compatible with other aerated-anoxic processes from USFilter Envirex Products, such as the Orbal™, Vertical Loop Reactor (VLR®), VertiCel™, Cannibal™ and BioNutre™ processes. It is also effective in providing control for any activated sludge process.

Lifecycle Costs

For aeration control, DO control significantly reduces power consumption in actual operation. To illustrate, a manually operated, single-stage oxidation ditch plant uses almost 40 percent more power than the same size three-channel Orbal™ plant using the SmartBNR™ system.

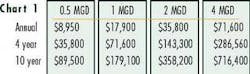

Matching the oxygen delivery rate to the oxygen demand will reduce power costs, providing savings. See Chart 1.

In the above example, the system is estimated to save at least four hours per week in labor for monitoring and controlling DO. Assuming a total labor cost of $55 per hour, this represents additional savings of at least $11,400 per year. A 0.5-MGD plant can recoup its initial investment in the SmartBNR™ process control system in less than four years. Larger facilities will see a quicker return on investment.

Additional power savings are gained through effective solids management in a plant. Labor savings provide the greatest cost savings for the system's sludge age control module. Effective process control is labor-intensive.

About the Author

John Sheridan is process engineer for the biological nutrient removal processes and smart controls at USFilter Envirex Products in Waukesha, WI. Sheridan joined USFilter in 1995, and has more than 10 years of experience in the water treatment industry. He has a M.S. degree in Environmental Engineering from Marquette University in Milwaukee, WI.