By John Civardi and Craig DeWitt

Radon is the second leading cause of lung cancer in the United States. Although not currently regulated, the U.S. Environmental Protection Agency's proposed rule is expected to be made final by the end of 2004 and will likely become effective in 2007. Given that there is relatively little industry experience removing high levels of radon from groundwater supplies and that developing a compliance strategy will require considerable human and capital resources, it is a good idea for municipal water suppliers to start preparing for the new rule now.

Compliance will require water resources agencies that deliver supplies from groundwater sources to understand: (1) the properties and health effects of radon; (2) technologies that are available to remove radon from groundwater supplies; and (3) how to select the optimum treatment equipment and processes that will ensure compliance with these new regulations and safeguard public health from the risks from radon.

Regulatory Update

In 1991, EPA proposed issuing a maximum containment level (MCL) for radon at 300 picocuries per liter ("pCi/L") in groundwater but withdrew its proposal due to inadequate data concerning costs of compliance, radon exposure health effects, and other issues. Nine years later, EPA revised its proposed rule to allow a maximum concentration of 4,000 pCi/L. This revised level — over 13 times higher than originally proposed — was based on a risk assessment undertaken by the National Academy of Sciences.

The proposed regulation provides two options to states and water systems to reduce exposure to radon.

Multimedia Mitigation Measures — States can choose to develop enhanced multimedia mitigation measures ("MMM") programs to address the health risks from radon. MMM programs are intended to reduce overall exposure to radon from both air and water sources and will involve a combination of education and possible funding for installation of household remediation measures. If the state or water supplier have an MMM, radon levels shall not exceed 4,000 pCi/L. EPA is encouraging states to adopt this option because it is the most cost-effective way to achieve the greatest radon risk reduction.

Reduce Actual Radon Levels — If a state chooses not to develop an MMM program, individual water systems would be required to either reduce radon in their system's drinking water to 300 pCi/L or develop individual local MMM programs and reduce levels in drinking water to 4,000 pCi/L. If radon levels exceed 4,000 pCi/L, treatment will be required and the agency or supplier will have to conduct a cost-benefit analysis to determine whether to achieve radon levels of either 300 p/Ci/L or 4,000 p/Ci/L.

Amendments to the Safe Drinking Water Act requiring Consumer Confidence Reports do not obligate water agencies to monitor for radon. However, if a water system does monitor radon in its groundwater supply, the agency must report its findings in the report.

Available Technologies

Municipal water professionals can consider implementing a wide range of technologies to remove radon from drinking water to achieve compliance with EPA's proposed rule. Each technology offers its own unique array of benefits and limitations. For example, although granulated activated carbon is highly effective in removing radon from groundwater, this technology is expensive and may generate radioactive waste as the radon is adsorbed on the carbon bed.

In its proposed rule, EPA ranks high performance aeration as the best available technology. The two most common forms of aeration that provide highly effective removal of radon are Packed Tower Aeration (PTA) and Diffused Bubble Aeration (DBA), both of which have been designated as best available technologies because of their effective and efficient record of removing other volatile contaminants from water, such as trichloroethylene and carbon dioxide.

Case Study

Officials in the Township of Sparta, NJ, were alarmed by the elevated radon levels of its Greentree and Autumn Hill well fields. Given that its radon levels approached 50,000 pCi/L, treatment was to be required, regardless of whether New Jersey adopted an MMM. With this in mind, and also knowing that federal regulations were eventually going to require some kind of action, Sparta officials decided to be proactive and take the initiative to protect human health and reduce radon levels.

Sparta's Greentree site contained three wells each with a capacity of approximately 50 gpm. Radon levels at the Greentree site were at concentrations ranging from 14,000 to 42,000 pCi/L. The Autumn Hill site contained two 50 gpm wells ranging from 20,000 to 50,000 pCi/L. The water from both sites had hardness ranging as high as 350 mg/L as CaCO3.

The first step was to evaluate packed tower aeration ("PTA") and diffused bubble aeration ("DBA") aeration technologies from both cost and operational perspectives.

The conceptual cost of the PTA system was determined to be approximately $130,000. The PTA system was comprised of a 3-foot diameter tower with 20 feet of packing, two highlift pumps, and a 5,000 gallon clearwell.

The conceptual cost of the DBA system was approximately $200,000 and was comprised of two 10' x 7' units located inside a building, two highlift pumps, and a 5,000 gallon clearwell.

The $70,000 difference between the PTA and DBA systems resulted from the need to expand the building to house the diffused bubble units. However, there were also operational concerns about the DBA units. In particular, Township officials were concerned about the potential maintenance issues stemming from carbonate scaling on the DBA diffusers.

Sparta Township selected the PTA systems for both the Greentree and Autumn Hill sites based on anticipated lower capital costs and simpler operation with less potential for fouling. What's more, unlike the DBA system, use of PTA technology did not require physical expansion of any plant facilities, thereby eliminating additional construction, permitting, design, and associated costs.

The township considered achieving radon levels below the 300 pCi/L, which translates to a 99% removal rate. This objective was made even more challenging since radon removal rates above 99% are virtually unprecedented and that little data exists regarding design parameters for such systems.

Hatch Mott MacDonald (formerly Killam Associates) ("HMM") conducted a pilot test to verify the theoretical parameters for PTA to remove nearly 99% of radon from these two well fields.

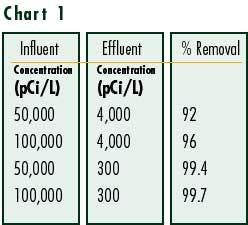

As part of the pilot test, HMM ran 16 trial tests with air to water ("A/W") ratios ranging from 5:1 to 30:1 and liquid loading rates ranging 24 to 34 gpm/sf. The pilot column consisted of 10 feet of 2 inch diameter Jaeger Tripacks®. HMM's testing demonstrated that 99% removal of radon could be achieved with a liquid loading rate of 30 gpm/sf and an A/W ratio of 30:1. With the pilot test data in hand, HMM evaluated the following four removal scenarios during the preliminary design phase of the project, see Chart 1

HMM determined that costs ranged between $32,000 for the tower to achieve 92% radon removal to $50,000 for a tower to achieve 99.7% radon removal. HMM recommended two facilities designed to remove 99.7% of radon from the Greentree and Autumn Hill wells.

HMM's final design parameters for the towers for each site are as follows:

Radon Concentrations: Influent 100,000 pCi/L; Effluent 300 pCi/L

Flowrate: 130 gpm

Tower: 2'-6" diameter stainless steel

Packing: 22 ft of 2" Jaeger Tripacks

Blower: 450 cfm, 1 Hp

The towers, of stainless steel construction, are mounted on a concrete clearwell and booster pumps are located in the existing well houses.

The Greentree and Autumn Hill facilities were completed and placed into service in January 2004. The construction cost for each of the two facilities was approximately $300,000. Testing performed at startup found that the effluent radon concentrations exceeded the design criteria and ranged between 50 and 200 pCi/L.

About the Authors:

John Civardi, P.E., is a project manager with Hatch Mott MacDonald and consults clients on the selection, design, and construction of diverse water treatment processes and systems. He can be contacted by e-mail at [email protected]. Craig DeWitt, P.E., is a senior associate with Hatch Mott MacDonald and consults clients on project implementation and construction of water treatment facilities. He can be contacted by e-mail at [email protected].