A State of 'Non-Emergency' Tier 4 Emissions Regulations and Their Impact on the Water Industry

By Ken Box

Nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO) and hydrocarbons (HC) all are harmful emissions produced by diesel-powered engines. Since the inception of the Clean Air Act in 1970, the Environmental Protection Agency (EPA) has sought to reduce them. While the concept of emissions-reduction regulations may not be a pressing concern to many water treatment plant operators, the need for reliable emergency standby power is still essential to a plant's successful uptime strategy.

Bridging these two seemingly competing interests, the EPA's Tier 4 interim emissions-reduction regulation will have growing importance throughout the water and wastewater industry.

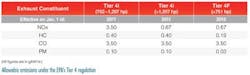

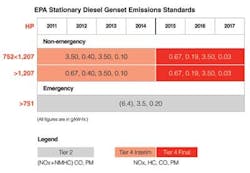

Now well into year two of its implementation, EPA's Tier 4 clean air initiative for high-horsepower non-road engines is being enforced in two phases: Tier 4 interim (or Tier 4i), effective Jan. 1, 2011; and Tier 4 Final (Tier 4F), effective Jan. 1, 2015. Water treatment utilities often require generator sets greater than 751 hp to ensure available power supply under any circumstance. Engines in this mission-critical power range fall within the EPA's Tier 4 jurisdiction and are subject to the enforcement of its two-phased emissions reductions.

Tier 4i requires significant reductions of NOx and PM emissions while maintaining operational flexibility for non-emergency use, and Tier 4F graduates these reductions to even stricter levels for high-horsepower generator sets. Since 4F certification cannot take place until one year prior to its effective date in 2015, all generator sets that currently meet 4F's stricter requirements are classified as "4F-capable" or "4F-ready."

Non-emergency Operation

At the end of the day, providing access to safe drinking water and basic sanitation is still the primary concern for water and wastewater treatment plant operators — and high-horsepower, diesel-powered generators are the preferred insurance against loss of utility power. But for those plant operators who seek to produce power for reasons beyond emergency standby purposes, they must be aware that all non-emergency operation is subject to the EPA's strictest emissions-reduction mandates.

The Tier 4i requirements set forth by the EPA's New Source Performance Standards (NSPS) are comprehensive, complex and at times confusing to most operators in the water industry. For some, the threat of fines for non-compliance has muddied the waters and given them a reason to re-think their operating strategies. In instances where local review boards have mandated even stricter requirements than the NSPS (see Non-attainment sidebar), some operators have already been instructed to install Tier 4i-certified generators. Others still have yet to feel the impacts of the EPA's Tier 4i regulations and continue to operate their existing Tier 2-certified generator sets for both emergency and non-emergency purposes. Regardless of where you fall in this spectrum, the time is coming where much of the water industry will be forced to address the Tier 4 standards in one way or another.

Like many roads that seem impassible from a distance, once one takes the time to fully investigate the path, many of the obstacles quickly disappear. The confusion around Tier 4 is no different. In fact, the question "Do I need a Tier 4i-certified generator set?" can usually be answered by simply considering the following two scenarios:

1) Does the plant I operate need to replace an existing or add a new generator set?

2) Do I plan on self-generating power for purposes other than emergency standby?

If the answer to both of these questions is "yes," then you should consider moving to a Tier 4i-certified generator set. In short, Tier 4i certification is needed if you plan on investing in a new generator set that will be used for non-emergency purposes.

Tier 4i certification gives plant operators the flexibility to fully explore non-emergency, self-generated power options, including the following common applications:

Prime power. Prime power refers to the option for plant operators to self-generate power in order to maintain uptime, improve reliability or augment utility power as needed. One example would be to self-generate power during anticipated periods of high demand to improve performance and increase stability.

Peak shaving. Peak shaving (or rate curtailment) is a process through which water treatment operators can participate in an arrangement with local power utilities, allowing the operator to produce self-generated power during the utility's peak demand periods and avoid incurring peak utility rates. This is particularly cost-effective in regions of the country where utility rates are well above the national average.

Storm avoidance. The practice of storm avoidance gives plant operators the flexibility to stabilize utility power in anticipation of power disruptions due to incoming storms. If utility power is lost, operators will have effectively avoided any service outage. In addition, the operator may also elect to self-generate power after utility power has been restored to allow time for a return to normal, stabilized power supply.

All generator sets built after Jan. 1, 2011, must be Tier 4i-certified to enable unlimited non-emergency operation. Plant operators must understand that the EPA considers all run time usage other than exercising and emergency purposes as "non-emergency" usage. For all generator sets that are not Tier 4i-certified, the EPA allows only a combined 100 hours per year of exercising, maintenance and non-emergency operation.

Aftertreatment Technology

Whether self-generating power for non-emergency scenarios, complying with non-attainment area regulations or responding to constituents that seek to reduce environmental impacts, plant operators who move to Tier 4i-certified generator sets all have one thing in common: They all rely on the best available control technology (BACT) to achieve EPA compliance.

High-horsepower generator set manufacturers have engineered emissions controls capable of meeting Tier 4F regulatory levels today, most notably by providing a dramatic reduction in HC and PM well below Tier 4i levels. These additional reductions are achieved by enhancing the add-on controls — or exhaust aftertreatment systems — required by the EPA to meet the 2011 Tier 4i regulation.

Emissions reduction on high-horsepower stationary diesel generator sets is achieved through a combination of existing selective catalytic reduction (SCR) technology and engineering innovations that reduce exhaust constituents to acceptable Tier 4i-certified (even Tier 4F-capable) levels.

Selective Catalytic Reduction (SCR) — To remove the NOx and PM required to achieve Tier 4i certification, generator set manufacturers have adapted this proven on-road, emissions-reduction technology for high-horsepower stationary applications. SCR works in combination with a diesel exhaust fluid (DEF) injection system to introduce DEF into the exhaust stream, monitor NOx surrounding the catalyst, and reduce it to Tier 4i-compliant levels.

Exhaust Pre-heater and Diesel Particulate Filter (DPF) — The additions of an exhaust pre-heater and DPF are required on larger stationary generator sets to reduce PM and NOx emissions levels. Pre-heaters are designed to rapidly heat exhaust to 450 degrees Fahrenheit, beginning the NOx conversion process in as little as nine minutes. In addition, DPF technology reduces PM up to 94 percent, bringing PM into Tier 4F-capable levels.

Tier 4i Certification Gaining Appeal

For all new generator sets built since 2011, only Tier 4i-certified systems provide the flexibility to operate during both emergency and non-emergency applications, with no limitations or concerns about allowable run time. While the Tier 4 watershed may not have occurred for many plant operators across the U.S., the advantages of Tier 4i-certification are quite apparent to those who choose to self-generate power for non-emergency purposes. And with regional ERBs dictating ever stricter standards, some operators may have no choice than to pursue the best available control technologies today.

About the author: Ken Box is employed by Cummins Power Generation as the southeast regional manager for Power Electronics. His current responsibilities include providing application engineering support for power generation products to customers in the healthcare, wastewater and data center industries. He is a published author, an active IEEE member and a licensed professional engineer. Box can be reached at [email protected].

Non-attainment Areas Make Tier 4 Compliance Mandatory

Regions throughout the U.S. where pollution reduces air quality below the EPA's current air quality standards are known as non-attainment areas. Typically governed by local environmental regulations boards (ERBs), these regions enforce more stringent emissions requirements than the EPA's national standards. Atlanta and Los Angeles are two regions where non-attainment areas have been established, though more and more cities throughout the U.S. are enforcing non-attainment standards (see Non-attainment regional map).

In many regions, Tier 4i certification is required to comply with these stringent regulations and may even be mandated for both emergency and non-emergency applications. Some ERBs enforce the use of Tier 4F-capable generators as the only technologically viable system capable of providing the necessary emissions scrubbing. Finally, it's important for water treatment plant operators to understand that these ERBs have authority to enforce compliance — and issue EPA penalties — to the fullest extent.