Media Expansion Monitoring Improves Filter Performance

By Dan Tumis

Optimum filter performance is a critical component of surface water treatment. And backwashing is the primary means to keep filters functioning properly to produce safe drinking water. One company has introduced a new system that monitors filter media expansion to help ensure that filters are adequately cleaned during backwashing and that media loss is minimized.

Monitoring backwash expansion can help optimize filter performance. Optimal expansion produces two key process effects: It fully fluidizes media grains allowing impurities deep in the filter to release, and promotes aggressive particle agitation which is required to remove sticky floc and dislodge material attached to media grains.

The backwash cycle typically begins with a low, sub-fluidized flow rate that produces little or no expansion but prepares the bed for the shock of higher flows. The high flow rate that follows fluidizes and expands the media grains. The desired effect is to expand the media grains to a point that the bed is fully fluidized (particles deep in the filter are suspended) and the rate of particle collisions produces an aggressive scrubbing effect.

Failure to secure vigorous media scrubbing will diminish the overall wash effect and can contribute to harmful mud-ball formation and sand binding.

The rate of expansion is determined by the rate of flow after consideration is given to: (1) type of media, (2) size of media grains, (3) uniformity of media grain size, and (4) water temperature. The number of variables involved, frequency of change in water temperature and complexity of the required calculation can result in undesirable and unknown rates of expansion at even the most conscientious filtration plants. The true wash effect is often unknown, and it is difficult to achieve consistency in backwashes.

A healthy, well operated and properly maintained filter is not only conducive to producing high quality water but is also more likely to have longer filter run times and reduced annual backwash cycles. Since plants use their product (treated water) in backwashing, this calculates directly into significant annual savings. Plants typically report expending 2.5% to 3.0% of annual production in filter backwashing - a cost of more than 200 million gallons of production in a 20 mgd plant.

Engineers, filter manufacturers and environmental regulators typically want backwash expansion (depending on variations in media type and characteristics discussed above) in the range of 25% to 50% of the media bed depth. However, experience with dozens of filter plants across the country illustrates frequent instances of actual expansion that are well below this level.

Direct, online measurement takes the guesswork out of this important process variable and supports operator efforts to optimize filter backwashing and secure consistent wash results.

Expansion Monitor

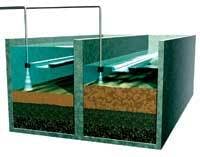

Entech Design offers the Expansion Pro Analyzer 2000TM, an application specific instrument designed to measure media expansion in granular media filters. The instrument employs the same underwater acoustic sensing technology that the company applies in sludge blanket and other industrial interface level analyzers. The device also provides a measurement of media depth and cumulative loss of media to give operators a quick reference to the status of each filter.

The system consists of an analyzer that is capable of operating from one to four sensors or transducers. Each sensor can be located up to 1,000 feet from the analyzer. The sensor is located just below the top of the wash trough so that it will be submerged when the filter is online and during backwash. An optional self-cleaning wiper sensor is available for applications where gas bubbles are known to percolate out of the media bed and could impede the signal if allowed to remain on the face of the sensor.

Measurements are made by transmitting a high frequency sound wave and measuring the interval between origin and reflection from the filter media below. Since the transmit speed is known, elapsed time can be converted to the distance between the sensor and the media. In combination with the known depth of media at initialization, the measurement is used to calculate Media Depth, Loss of Media and Expansion during backwash.

Initialization and ongoing operation of the instrument are simple. On power up, the operator is prompted to enter: (1) Distance from Sensor to Media, and (2) Depth of Media. The instrument then runs through an automatic start-up and calibration routine and is ready for filter backwashing in less than a minute. Orientation to the current depth of the media is automatically maintained.

During backwash, the operator has access to local indications of expansion in engineering units and as a percent of media depth. A separate instrument display view shows the current depth of media and cumulative loss of media in all filters. A 4-20 mA signal is provided to the customer SCADA or other control system for process monitoring and control.

Field Experience

The Entech system is currently in operation in dozens of filters across the US ranging from small plants with several filters to a 150 mgd plant with 56 filters. Instruments are used for both process monitoring and active process control. Mono-media, dual media and mixed-media filters are appropriate for the instrument. Recent installations have included ground water pressure filters.

A 20 mgd Ohio plant uses the instrument for direct process control by varying its wash water rate to secure the desired amount of expansion rather than using a stipulated rate of flow. One plant recently identified a faulty backwash pump check valve and another found a faulty flow meter by observing unexpected reductions in expansion.

A plant in the US Northwest is working with the manufacturer to study the relation between backwash turbidity and the duration of the high rate wash. Early data suggests that correlating media expansion with backwash turbidity may support a reduction in high rate wash duration with the consequent reduction in wash water expenditure. An integrated turbidity meter has been developed by the manufacturer and will soon be available to provide an inexpensive dual measurement capability.

About the Author:

Dan Tumis is a Regional Manager for Entech Design, based in Denton, TX. The company specializes in interface level analyzers. In addition to filter backwash analyzers, the company manufactures sludge level analyzers for the water and wastewater treatment industries. More information on the company and its products can be found at www.entechdesign.com.