Energy Efficient Membrane Plant Protects Sensitive River

By Chris Kelsey, Tom Giese, and James Kelly

Rainfall and melted snow from the Cascade Mountain Range feed into the North Fork and South Fork of the Stillaguamish River in northwest Washington. The two forks converge near Arlington to form the river proper, which flows for 45 miles to Puget Sound. The Stillaguamish and its tributaries are home to eight species of salmon that return to their native streams each year to spawn.

The Washington Department of Ecology (Ecology) has established Total Maximum Daily Loads (TMDLs) for the Stillaguamish to protect water quality, the salmon runs, and the tribes and cities downstream that depend on the river. In response to these new standards and projected population growth, the City of Arlington is planning new upgrades to its wastewater treatment plant that not only comply with the new discharge limits but also save energy costs and benefit the environment.

Value Engineering

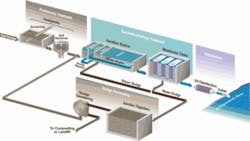

The city’s two major goals are to provide for future growth and to upgrade the treatment process to meet new discharge limits. The city’s population is expected to double by 2025 as the Arlington plant serves a growing number of neighboring communities. To maximize the existing resources and produce the best effluent water quality, the city chose membrane technology to upgrade its wastewater treatment. The design reuses two existing 1.3 million gallon tanks that currently operate as sequencing batch reactors (SBR).

During the membrane selection process, Kennedy/Jenks Consultants studied alternatives that use hollow fiber membranes and flat-plate (sheet) membranes. Although both types of membranes offered significant benefits, the flat-plate membrane system offered the best overall project value. The selected membrane bioreactor (MBR) system eliminated the need for flow equalization by taking advantage of higher allowable peak membrane flux, due to larger pore size of the flat-plate membranes.

With the addition of just five percent more membrane area compared to the initial design value, enough membrane capacity would be provided to treat the peak design flow without flow equalization, as opposed to adding nearly 40% more membrane area with hollow-fiber membranes. This resulted in a more efficient use of existing structures and fewer additional structures.

The initial design had one of the SBR tanks being converted to aeration basins and the other to a flow equalization tank to reduce requirements for membrane area. Eliminating the need for flow equalization allowed the second SBR tank to be converted for aerobic digestion, thereby eliminating the need to construct new digester tanks. Furthermore, the selected flat-plate membranes required 3 mm screening, as opposed to 2 mm screening for the competing hollow-fiber membranes.

The initial design had two-stage screening to reduce loading to the 2 mm fine screens. By changing to 3 mm fine screens, the city felt comfortable with eliminating the coarse screens and having only one stage of 3 mm fine screens. Also, the larger screen openings provide the same hydraulic capacity with fewer screens. All told, the selection of flat-plate membranes translated to an estimated construction cost savings of $5.1 million.

The upgrade will allow expansion of the plant through two construction phases to a capacity to 4 mgd to accommodate growth. It also replaces the SBR system with a more efficient MBR system.

“Kennedy/Jenks solicited input and advice from the operations crew when designing this upgrade,” said former Wastewater Utility Supervisor David Randolph. “This was the proper approach since the crew will be the ones who will ultimately operate the plant, and they need to take ownership of this project during the design phase.”

Energy Savings

Although membrane systems are generally more energy-intensive than conventional systems, the flat plate membrane design offered energy saving opportunities. Because they have a larger pore size, a lower transmembrane pressure was used drive the same volume of water through the membranes. This allowed permeate to flow through the membranes and discharge to the river by gravity within the constraints of the plant’s current hydraulic profile. As a result, the permeate pumps need only run during high-flow or high river level operating conditions.

There was also an opportunity for savings in the aeration system. Because air is used to scour the membranes for cleaning, there is an opportunity to use the oxygen enriched mixed liquor recycled from the membrane tanks to offset the oxygen demand in the biological process. Recycling the oxygenated mixed liquor to the swing zones, rather than the anoxic or anaerobic zones, helps maintain anoxic and anaerobic conditions in those upstream zones for better nutrient removal performance, and reduces the oxygen demand in the aerated zones. This is achieved because much more of the dissolved oxygen in the recycle stream is available for use than if it was recycled to and consumed in the upstream anoxic or anaerobic zones.

Due to the reduced aeration demand for the biological process, the existing blowers had sufficient capacity to meet the peak aeration demands, while still retaining one existing blower as a standby unit. This eliminated the need to add blower capacity and expand the existing blower room. The existing blowers will be reused and retrofitted with adjustable frequency drives to make them more energy efficient.

The aeration basins and digesters will use high-efficiency strip diffusers for fine bubble aeration. Although the cost of the strip diffusers is significantly more compared to tube and disc diffusers, the longer diffuser membrane life and lower energy requirements resulted in a lower projected operation and maintenance cost. The strip diffusers were estimated to reduce energy consumption for aeration by about 10 percent. The 20-year net present values of the different diffuser types were less than 3 percent apart, but the city selected strip diffusers in anticipation of rising energy costs.

Also, the aeration basin diffusers are designed to allow for tapered aeration, with DO concentration highest upstream where oxygen demand is the greatest and lower downstream where there is less demand. Tapered aeration can reduce the air demand by about 20 percent without significantly affecting nitrification or phosphorus removal.

Other energy savings come from using controls that alternate airflow to the digesters, resulting in lower airflow and lower dissolved oxygen. This saves energy by reducing aeration and allows simultaneous nitrification and denitrification, which enhances nitrogen removal and recovers alkalinity necessary to buffer pH levels. Air will be alternated between the two digesters to maintain a low DO of about 0.5 mg/l and maintain solids in suspension. Alternating air to the two digesters also eliminated the need for a third blower, since one blower could serve both digesters.

The city will be able to apply for rebates from their energy utility for some of the equipment retrofits due to expected energy savings.

Wetlands Discharge

As part of this project, the city is constructing a stormwater wetland on the banks of the Stillaguamish next to the plant. The 27-acre site will have walking trails and viewing sites for the citizens of Arlington. The stormwater wetland will take stormwater from the Arlington area and treat it before it reaches the Stillaguamish.

During summer, when the river is low, and DO and temperature levels are most critical, the city will use the wetland as an alternative discharge site for the reclaimed water from the WWTP. The effluent will keep the wetland nourished during dry periods when there is no stormwater runoff and provide an additional measure of nutrient removal and cooling. Other potential uses for plant effluent will be for irrigation in the city cemetery and some farms near the WWTP that grow hay and field corn for cows. As the city updates its comprehensive plan for water, they will be evaluating other potential uses for reclaimed water.

Environmental Benefits

City management has made a commitment to environmental stewardship, as shown in their decision to upgrade the plant using the best technology available – membrane filtration – so that the water discharged to the Stillaguamish is of very high quality. It is also reflected in the city’s plan to treat stormwater runoff before discharging it to the river and to divert plant effluent to the wetlands in the summer. The following table provides an overview of the design effluent values and the plant performance predicted at the design flows and loads from the calibrated process model.

To achieve this level of performance, in addition to membrane filtration, one of the existing SBR tanks will be divided into three aeration basins. Each basin will be subdivided into an anaerobic zone, anoxic zone, swing zone, and two aerobic zones. The anaerobic zone is designed to stimulate the growth of phosphorus accumulating organisms that will store excess phosphorus in the aerobic zones and remove it from the wastewater.

The anoxic zone will provide denitrification for nitrogen removal and alkalinity recovery. The aerobic zones will provide oxidation of carbonaceous biochemical oxygen demand and nitrification of ammonia. The swing zone is designed to be either aerobic or anoxic. During colder winter months when nitrification is slower, the swing zone could be aerobic to provide additional aeration capacity for nitrification. Otherwise, the swing zone would normally be anoxic to enhance denitrification and alkalinity recovery.

The Washington Department of Ecology was primarily concerned about the role of phosphorus when they issued the dissolved oxygen TMDL. When the new plant goes on line, there will be a 75% reduction in phosphorus load. Phosphorus allows algae to form in the river, using up oxygen in the water and impacting fish and aquatic life. The upgraded plant will not only meet the anticipated permit limits but will also support the city’s commitment to be stewards of the environment (particularly the Stillaguamish), and benefit the community and all who use the river for habitat, recreation, and water supply.

About the Authors:

Chris Kelsey is Project Manager for Kennedy/Jenks Consultants, Federal Way, WA, and may be contacted at [email protected]; Tom Giese is Process Lead for Kennedy/Jenks Consultants in the Federal Way office and may be contacted at [email protected]; James Kelly is Public Works Director for the City of Arlington, WA, and may be contacted at [email protected].