By Lisa Woolard, P.E. and Michael Sparks

A tourist lodge on the Kenai Peninsula in the US state of Alaska replaced its septic tank and a mound leach field system with a membrane bioreactor system that provides flexibility to accommodate seasonal changes and an anticipated increase in wastewater flow, and continue the option for subsurface discharge.

Alaska's growing tourism industry has fuelled the construction of facilities to serve the lodging and entertainment needs of seasonal visitors. As the size of these facilities expand from small lodges and bed and breakfast type businesses to larger full service resorts, more sophisticated wastewater treatment facilities are required.

The Kenai lodge faced a number of constraints in the selection of a wastewater treatment system. Perhaps the most important constraint was to maintain the option for subsurface discharge into the existing mound system at the increased wastewater flow rates anticipated for the expanded facility. The State of Alaska requires that sufficient area be set aside for a replacement system if subsurface discharge is used for wastewater disposal. The lodge had adequate replacement area set aside for the existing mound adsorption system. Construction of additional mounds (and associated replacement area) to accommodate increased wastewater flows would occupy a significant portion of the available property. Use of the existing adsorption system was complicated by observations of ponded water in monitoring tubes, which indicated that discharge from existing septic tanks had compromised the adsorptive capacity of the mounds.

To maximise the potential for long-term use, the lodge required a wastewater treatment system that would minimise the soluble organic and particulate load to the subsurface adsorption system. The lodge also required a system that could be operated by the maintenance staff with limited prior wastewater treatment training and experience. The treatment system needed to operate throughout the peak and shoulder seasons and be shut down during the off-season. Finally, the treatment system needed to blend unobtrusively into the lodge complex. Consequently, project engineers selected an Ionics submersed membrane bioreactor (MBR) system. The Ionics MBR uses Sterapor™ hollow fibre membranes with a 0.4 micron nominal pore size placed directly into the aeration tank.

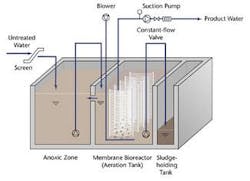

Ionics provides course bubble aeration to create a continuous flow of mixed liquor around the membrane module and the oxygen required for microbial degradation of waste components. The fibres in the Sterapore module are horizontally aligned, which allows for sufficient contact of air and membrane fibres. The system is operated on an 8-minutes-on and 2-minutes-off schedule. The filtrate pump pulls a vacuum on the membranes with the blower operating for 8 minutes at which time the pump turns off and the blower continues to run. This 2-minute period allows for the membranes to relax, which improves air-scouring efficiency.

Figure 1 - MBR Process Schematic

To provide flexibility in operation, the MBR tank at the lodge was divided into four separate aerated tanks each with a working volume of approximately 1,800 gallons. Each aeration tank is large enough to fit one membrane module. Three modules were initially installed to provide a treatment capacity of 20,800 gallons per day (gpd). The fourth compartment was provided for a future upgrade if necessary. The four aeration tanks share a common anoxic zone with a working volume of up to 8,600 gallons for equalisation and denitrification of the wastewater. All wastewater passes through 1/16- inch wedge-wire rotary drum screen before entering the membrane tanks. A schematic of the MBR System is shown in Figure 1.

Operational issues and system performance

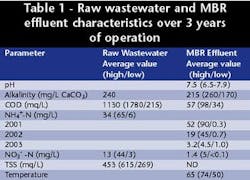

The facility started with raw wastewater in May 2001 and has continually operated for more than two years. The lodge generates a particularly strong waste stream with chemical oxygen demand (COD) values typically in excess of 1,000 mg/L. Effluent COD falls consistently below 60 mg/L since start-up, regardless of waste strength.

Nitrogen removal results were less consistent. Limited nitrification was observed during the 2001 season. Since the MBR was started from only raw wastewater, much of the first season was likely required to develop an active culture of nitrifiers. In addition, the high waste strength generated by the lodge exceeded the design waste strength. As a result, the aeration capacity initially provided was inadequate to consistently meet oxygen demand. Based on the results of the first season of operation, additional blower capacity was installed in 2002 and an aeration header added to one end of the anoxic tank to provide more aerobic detention time during peak months. These modifications improved nitrification during the second and third year of operation, resulting in consistently low levels of effluent nitrate since start-up.

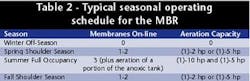

One unique aspect of this installation is the need to accommodate distinct wastewater flow characteristics that result from seasonal operation. By varying the number of membranes on line, MBR capacity can be matched with the wastewater flow rates that range from less than 500 gpd to over 13,000 gpd. The aeration system was designed so that aeration capacity could be matched to number of membranes on line. Table 2 summarises a typical seasonal operation schedule.

The membranes have performed well throughout both seasons of operation, producing an effluent with no detectable suspended solids. A consistent operational issue since start-up has been clogging of the membrane unit course bubble aeration headers with a hard, fibrous substance. Accumulation of this substance in the headers causes an increase in blower backpressure and a reduction in membrane agitation/aeration efficiency. Despite regular purging of the aeration header using blower air, by August 2001 the membrane aeration headers were plugged to the extent that membrane modules were removed and aeration headers were manually cleaned.

Manual ball valves were installed on the membrane aeration header to facilitate frequent header purging with blower air for the 2002 season. Weekly header purging kept fouling under control; however when system MLSS concentrations approached 20,000 mg/L late in the season, rapid aeration header plugging occurred that could not be mitigated by purging the aeration header with blower air. Consequently, the membranes were removed and the headers manually cleaned. In 2003, aeration header plugging has been successfully managed by maintaining MLSS concentration at 15,000 mg/L or less and purging the air header several times per week.

Significant foaming was observed during start-up in 2001 until a stable culture of biomass was established. Foaming also occurred for approximately one week after the MBR was placed back on-line in 2002 and 2003. No foaming occurs once this seasonal start-up period is completed. Although short in duration, this annual foaming event is problematic unless foam control is provided. Operating experience indicates that tap water supplied through low volume spray nozzles will provide effective foaming control.

MBR effluent discharge improved the performance of the mound adsorption system. No standing water has been observed in the monitoring tubes since the MBR has come on line and the existing adsorption field easily accepts the increased effluent generated by the expanded lodge facility.

Lodge staff with general electrical and mechanical skills, but limited formal training in wastewater treatment, routinely conduct MBR system operations. Main operational duties include routine system checks and removal of screened solids and sludge wasting. Waste solids are trucked off-site approximately one each week during the season peak. Operators only routinely collect the MLSS and flow data necessary for operation of the facility because effluent is discharged to a subsurface adsorption system. On average, the lodge staff spends less than two hours per day at the facility. Approximately three- to five-person days each spring are required to bring the system back on line. Approximately four- to seven-person days are required each fall to drain, clean and prepare the system for off-season storage.

Implementing MBR treatment has allowed the lodge to continue to use the existing mound systems thus preserving site acreage for guest units and support structures. With its four separate aeration tanks, the MBR provides the flexibility to match system capacity with the variable flows that occur during seasonal operation. Other than a period of brief foaming during start-up in the spring, storing the membranes in chlorinated clean water during the off-season has caused no operational problems.

Authors' NoteLisa Woolard, P.E. is a partner in GV Jones & Associates, Inc., based in Anchorage, Alaska. For more information, contact her by email at [email protected]. Michael Sparks is an engineer at Ionics, Incorporated, located in Watertown, Massachusetts, USA, Website: www.ionics.com.