Ultrasound enhances sludge digestion

By Fiona Hogan

The patented technology sonix™, developed by the UK company Sonico, uses high frequency ultrasound to destroy cell walls in secondary sludge, which improves downstream sludge processing. Sonico is a joint venture formed by two UK companies Atkins Consultants and Purac Ltd.

Although the application of sonix is novel, the use of ultrasound is not new. Ultrasound is sound energy at frequencies above 20 kHz and is typically generated using a transducer.

The novelty of sonix is the radial horn, the part that vibrates and emits ultrasound energy into the fluid. In most systems, the ultrasonic horn is a probe or block horn. The intensity of the ultrasound emitted from these common devices decreases rapidly as the sound waves radiate away from the horn, which limits the effective zone of cavitation. Sonix, however, differs from the typical block or probe-type horns by its unique radial horn that is designed to focus the sound waves as they are emitted from outer surfaces. This control creates a known zone of intense cavitation, which is very effective at enhancing cell lysis.

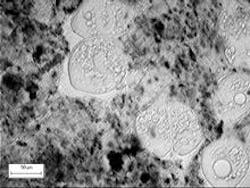

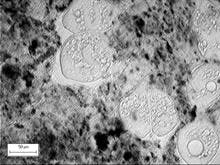

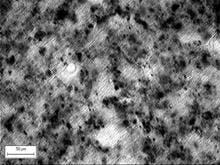

Cavitation is the formation, growth and collapse (or implosion) of micro bubbles within a liquid, which generates high temperature and pressure "hotspots." Understanding, quantifying and controlling the effects of cavitation is an important factor in determining the successful use of high power ultrasound.

Cell lysis is often the rate-limiting step in conventional anaerobic digestion. It prevents the complete release of intracellular organics for consumption and conversion to biogas by microbes; however the shock waves produced during ultrasonic cavitation enhance the rate of cell disruption/lysis. This reaction increases the substrate material (otherwise unavailable) for complete digestion. The physical action caused by cavitation also reduces particle size distribution of the sludge, therefore increasing the number of sites available for microbial action.

Full-scale demonstration trials using sonix technology have been completed within the UK and the USA with major water companies such as Thames Water, Severn Trent Water, Wessex Water, Anglian Water, Yorkshire Water, North West Water and the Orange County Sanitation District in the USA. These trials demonstrated conclusively that sonix enhances sludge digestion. A trial at Orange County Sanitation District, California showed an increase in biogas production and corresponding enhanced solids destruction resulting from sonix operation. The digester-feeding regime decreased from 60% secondary sludge to only 20% of total feed volume upon trial completion.

An additional benefit of sonix includes better de-waterability of the final sludge cake. Typical improvements at Orange County, for example, ranged between 1.2 - 2.6 percentage points higher solids for the test digester compared to the control, using identical dose rates of polymer.

Tests proved that sonix enhances digester operation and stability at high secondary sludge loading rates, including the control of filamentous outburst and any problems associated with digester foaming. The process also facilitates increases of soluble COD (chemical oxygen demand) and release of VFAs (volatile fatty acids); therefore its application can enhance the BNR process, which is often carbon limited.

In summary, the application of sonix in sludge treatment can increase gas production, solids destruction reducing the volume for disposal, and solids content in cake; improve digester stability; and reduce foaming and disposal costs.

Author's noteFiona Hogan, a scientist involved in research and technology development in Atkins Water, currently works at Atkins' Epsom, Surrey office in the UK; otherwise she is based in California, USA. For more information, send requests to Email: [email protected] is an independent multi-disciplined engineering consultancy, based in the UK. Purac Ltd, a division of the Anglian Water Group, is a process contracting business working in the water and wastewater industries.