Reducing Middle East water and power stations' costs

By Daniel Hoffman, Amnon Zfati

Some of the largest seawater desalination plants in the world are operating today in the Middle East along the Gulf and Red Sea coasts within dual-purpose water and power stations.

Desalinated water costs from these stations, despite their economies of scale, low OPEC countries' internal fuel costs and the benefits of cogeneration, are US$1 to US$1.4 per cubic metre (m3). Desalinated seawater costs elsewhere in the world, with smaller plants and almost three-fold higher, non-OPEC countries' energy costs, range between 65 to 95 US¢/m3, and the recently bid water sale prices for large-scale plants to be installed within BOOT and BOO schemes, are only 50-60 US¢/m3.

The causes for these disparities in water production costs, and the benefits that may be gained if hybrid membrane and/or thermal desalination plant schemes based on advanced, but currently available technologies and designs are adopted, have been analysed and discussed in a study prepared under the sponsorship of the Middle East Desalination Research Center (MEDRC) in Muscat, Oman.

The study's objective, as defined by MEDRC, was "to reduce the cost of seawater desalination and electrical power production through the innovative combination and integration of membrane desalination, thermal desalination and power generation technologies."

To establish the economic basis and the framework for the study, existing Middle East dual purpose stations' types of plants, capacities and performance figures and the regional water and power demands they serve were surveyed and their production costs quantified at both OPEC and non-OPEC fuel prices. It was upon these costs that the study's proposed and/or examined plant designs and schemes had to improve.

In 1997 about 330 seawater distillation units were operating throughout the world on co-generated steam. The total water production capability of these distillation units was roughly 6,900,000 m3/day. About 88% of the units and 95% of total capacity were installed in oil-producing Middle Eastern countries within large regional water and power dual-purpose stations.

By 2002 the number of seawater distillation units operating world-wide within water and power cogeneration stations increased to about 420 and their total capacity grew to about 9,400,000 m3/day. Middle East plants still account for about 95% of this capacity.

Multi-Stage Flash (MSF) type distillation plants predominate in Middle East oil-producing countries, accounting in 1997 for about 91.6% and in 2002 for about 80% of total installed desalination plants capacity. The most common dual-purpose power plants supplying co-generated steam to these plants were extraction/condensing steam turbines (E/CSTs), gas turbines with heat recovery boilers (GT/HRBs) and, to a lesser extent, back-pressure steam turbines (BPSTs).

The top brine temperatures (TBTs) and gained output ratios (GORs) of most of the MSF plants are relatively low, 90ºC to 1100C and 6:1 to 9:1, respectively. Their electrical energy consumptions are on the order of 3.5 to 4.5 kwh/m3. Power plant co-generated steam pressures were, typically, 2 to 3 bar absolute.

The cost of generating power from these stations was calculated on the basis of world prices for equipment and typical heat rates of the most efficient single-purpose power plants corresponding to each type of dual-purpose power plant - condensing steam turbines (CSTs) representing BPSTs and E/CSTs and combined cycle GT/HRB/CSTs representing GT/HRBs. The added power production costs due to dual-purpose power plant operation, i.e. lower power outputs and higher heat rates resulting from steam extraction or backpressure in E/CSTs and BPSTs or non-use of co-generated steam to produce additional power in GT/HRBs, served as the basis for calculating co-generated steam and, eventually, thermal desalination plants' heat input costs.

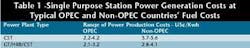

At typical OPEC and non-OPEC fuel prices (1.2 and 2.7 US$/GJ, respectively), power generation costs from single purpose CST and GT/HRB/BPST power plants should be within the ranges shown in Table 1.

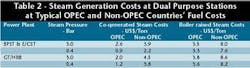

The cost of co-generating steam within the dual purpose stations, as a function of power plant type and steam pressure at typical OPEC and non-OPEC countries fuel prices, should be as shown in Table 2. For comparison, and to demonstrate the benefits of co-generation, or vice versa the penalty for non-co-generation due to water and power demand mismatches, boiler raised steam costs are also presented in Table 2. The benefits of using lower pressure co-generated steam (significantly lower costs due to the much smaller loss of power production output and efficiency) are clearly seen.

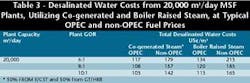

The current costs of producing desalinated water from typical large Middle East countries' MSF plants, at typical OPEC and non-OPEC fuel costs as a function of GOR and source of 3.0 bar steam, are shown in Table 3.

Table 3 figures show that:

• At the low OPEC internal fuel costs the difference in desalinated water costs when using co-generated and when using boiler raised steam is only 10-15%.

• If the external world-wide fuel costs were used as a basis, desalinated water costs in the OPEC countries dual-purpose stations would be not on the order of 1-1.2 US$/m3, but in the range of 1.4-1.8 US$/m3.

• Specifying and installing higher GOR plants will reduce desalinated water costs at all fuel cost situations and, more importantly for minimising the effect of water and power demand mismatches, increase the station's water to power ratio.

The power costs presented above are based on annual utilization factors (50-70%) typical for single-purpose stations throughout the world and on the continuous use of co-generated steam by the MSF desalination plants. In fact, due to large fluctuations in power demand in many Middle East countries (peak to minimum demand ratios on the order of 4:1 to 5:1), the annual utilizations of their power plants are low (on the order of 40%), thereby penalising power production costs.

Furthermore, water to power demand ratios (W/P) during low power demand periods are 700 to 1,600 m3/day/MW, whereas the W/P output ratios of the existing dual-purpose stations are only 400 to 900 m3/day/MW. As a result of this disparity, water and power supply and demand mismatch situations occur, requiring the operation of the desalination plants, partially with steam raised directly by fuel-fired boilers, thereby increasing water production costs.

The economic consequences of these mismatch situations were found to be:

• An increase of up to 0.5 US¢/KWh in power production costs vis-à-vis well used power plants.

• An increase of up to 4 US¢/m3 in water production costs at OPEC fuel costs, or up to 12 US¢/m3 at non-OPEC fuel costs, if desalination plants are operated for 30% of the time without the benefits of co-generated steam.

The key causes for the mismatch problems, besides the large periodic variations in power demand, are:

• Low internal fuel costs in most Middle East countries that encourage use of low-efficiency, low-GOR distillation plants and reduce the economic significance of the mismatch problem and the entire benefits of cogeneration.

• An almost exclusive dependence on MSF plants and a conservative attitude regarding the adoption of other, more efficient, higher GOR distillation processes that allow higher W/P ratios.

• Insufficient use of BPST power plants that offer the highest W/P ratios, for base load operation with high efficiency distillation plants.

• Water and power are priced by social rather than economical considerations and not on the basis of actual production costs and/or profitability targets. Subsidies are common and there are no consumer incentives to reduce water consumption. As a result per capita water consumptions are high.

• No TOU seasonal and/or hourly power tariffs to discourage use during peak demand periods and encourage use during valley demand periods.

The approach adopted for achieving the study's objective is to analyse, quantify and compare cost reductions that may be achieved, in six basic sets of situations and conditions - existing or new, small-medium or large dual-purpose stations, at OPEC or non-OPEC countries fuel prices - through:

• More economical and flexible desalination plant designs;

• More economical and flexible mixes and combinations of power plants;

• More efficient steam cogeneration and/or heat recovery from dual-purpose power plants;

• Process benefits and synergetic savings in investments and operating costs due to the combining of desalination and power plants within hybrid cogeneration schemes;

• Increasing the annual use of power plant equipment by adding power consuming desalination plants.

The various hybrid, thermal and membrane desalination plant schemes proposed to date, including a preferred scheme, will be examined in Part 2 of this three-part series. Part 3 will cover the potential benefits of the above cost-reducing solutions.

Authors' noteDaniel Hoffman and Amnon Zfati of ADAN Technical & Economic Services Ltd., Tel Aviv highlight the main points of their MEDRC-sponsored study in a three-part series. Part 2 and 3 will follow in the May and June 2003 issues of WWI. The full study may be downloaded from MEDRC's web site: www.medrc.org.om, by clicking on "Research Program", then on "Final Reports", and on Project No. 97-AS-008a.