Reducing Middle East water and power stations' costs

By Daniel Hoffman, Amnon Zfati

Process benefits and synergetic savings in capital and operating costs are possible by combining thermal and membrane seawater desalination plants within hybrid schemes. This has been known since 1970 when the first seawater reverse osmosis (SWRO) and thermal desalination plant hybrid scheme was suggested. Since then this concept has been examined by numerous investigators, who have proposed four additional schemes.

Cost reductions are due to the:

• Use of a common and smaller seawater supply system;

• Ability to extend membrane lifetime (beyond the normal cut-off point due to increased salt passage) by blending SWRO and distillation plant products;

• Ability to increase and control SWRO plant feed water temperature and membrane performance; and

• Ability to integrate seawater pretreatment and product post-treatment systems.

In Middle East dual-purpose water and power stations, water and power demand mismatches are frequent, requiring partial use of direct fuel-fired boiler steam as heat input to thermal desalination plants during low power demand periods, in lieu of lower cost cogenerated steam only. The addition of a power-consuming SWRO plant provides for these stations an additional benefit - a higher water to power ratio (W/P), i.e. increased cogenerated steam output.

All five potential hybrid desalination plant schemes proposed to date were reviewed within a study sponsored by the Middle East Desalination Research Center (MEDRC) in Muscat, Oman, and the cost savings resulting from one preferred scheme, operating within a typical Middle East dual purpose station, were quantified at OPEC and non-OPEC countries' fuel prices.

The hybrid scheme selected is the most common and straightforward scheme of all. It uses part of the thermal desalination plant's heated coolant reject as the feed to the SWRO plant and both plants' products are blended.

The potential cost savings from this selected hybrid scheme, not taking into account (yet) the benefits of increased co-generated steam output due to the power consuming SWRO plant's load, are a function of SWRO and distillation plant output ratio. This ratio, in turn, depends on thermal plant gained output ratio (GOR) and resultant seawater coolant requirements. For a typical Middle East thermal desalination plant, an MSF plant with a GOR of 7.6:1, the optimal SWRO to thermal plants' output ratios were found in the study to be in the range of 1.5-3.0, the peak being at a ratio of about 2:1.

The total savings for a 150,000 m3/day capacity hybrid plant at the peak 2:1 ratio (100,000 m3/day SWRO and 50,000 m3/day thermal) were calculated as 4.8 US¢/m3, or about US$ 2.4 million annually. The present value of this annual saving, at 7% interest and a 20-year depreciation period, is about US$ 25.3 million.

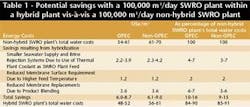

To put these savings in a better perspective, all the process and common infrastructure, labour and services benefits were credited to SWRO plant water production costs, and all the benefits due to increased co-generated steam output (to be presented below) to the thermal desalination plant's water costs. The magnitudes of these savings, absolutely and relative to desalinated water costs from an equal-sized 100,000 m3/day stand-alone, non-hybrid SWRO plant, at both OPEC and non-OPEC countries' fuel prices are presented in Table 1.

Two facts are brought out by Table 1 figures. First, desalinated water costs from current stand-alone, non-hybrid SWRO plants are considerably lower than those of even the most efficient, 10:1 GOR MSF plants operating in the region. Second, if the savings derived from the SWRO/MSF hybrid plant scheme are all assigned to the SWRO plants' product costs, these relatively low figures will even be reduced further by 6 to 9 US¢/m3.

The optimal modes of operating SWRO plants (in stand-alone or hybrid plant schemes) within dual-purpose stations plagued with water and power demand mismatch problems were analysed in the MEDRC study and their benefits quantified by calculating and comparing five points:

• The effect of the additional electrical load imposed by SWRO plants' operation on the availability of co-generated steam and resultant thermal desalination plants' water production;

• The corresponding credit due to SWRO plant economics from savings in thermal desalination plants' steam supply costs during low power demand periods;

• The SWRO plants' capital recovery and total water costs as a function of annual use, i.e. the effect of operating only on existing-system available (idle) power generation capacity, without addition of any power generation capacity, and assuming that some of the SWRO plants' capacity may have to be idled during peak power demand periods;

• The SWRO plants' energy cost component if only idle power capacity is used and this power is charged at valley Time of Use (TOU) power tariff rates based on marginal operating costs with various percentages of fixed costs;

• The economics of intermittent power production if an optimal power plant, sized to meet the SWRO plant's power requirements, is added to enable operating the SWRO plant continuously, also during peak demand periods.

Due to the continuous reductions in SWRO plants' specific energy consumptions over the past five to ten years, these plants' potential contribution of a welcome additional load during low power demand periods has been significantly diminished. Each 1 m3 of SWRO product will cogenerate an additional amount of steam sufficient to produce only about 0.2 m3 of product from existing 6:1 to 10:1 GOR MSF plants where a high W/P ratio back-pressure steam turbine (BPST) is used and as little as 0.04 m3 to 0.08 m3 where gas turbines with heat recovery boilers (GT/HRBs) are used.

The resultant savings in the cost of steam supply to these thermal plants, per 1 m3 of SWRO product, are about 2 US¢/m3 for the BPST and 1.5 US¢/m3 for the GT/HRB, at OPEC countries' fuel costs, and 4.3 US¢/m3 and 3 US¢/m3, respectively, at non-OPEC countries' fuel costs.

Comparing these steam cost savings with the increases in SWRO plants' capital recovery and total water costs if the plants are idled during peak power demand periods, i.e. no additional power generation capacity is added, shows that the installation of SWRO plants to create an electrical load, where mismatch problems exist, is justified only in non-OPEC countries whose power supply can meet peak demand plus SWRO plant load for at least 80% of the time.

However, if reasonable seasonal and hourly TOU power tariff rates are introduced, the resultant reductions in SWRO water costs will justify the installation of SWRO plants in non-OPEC countries (only) also where power supply can meet peak demand plus SWRO plant load for only 70% of the time.

Auxiliary gas turbine (GT) plants, without HRBs, are the simplest and most economical power plants for supplying power to the hybrid SWRO plants where their continuous operation, even during peak power demand periods is warranted.

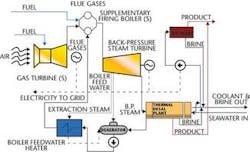

The study's preferred system for supplying heat and power continuously to all hybrid desalination plant schemes uses a combined-cycle GT/HRB/BPST power plant, consisting of several GTs coupled to supplementary firing HRBs that supply steam, via a common header, to one or two BPSTs (see Figure 1).

Main elements of scheme: The sizes and numbers of GTs operating in parallel will allow for equipment economies of scale, but will take into account operation at partial outputs within a reasonable range from their design points.

The number of operating GTs and their load distribution will be controlled according to non-desalination plant (i.e. external) power demand. They may all be shut down during low power demand periods.

The HRBs will use GT exhaust gases at all times and be supplementary fired only during shutdown of some or all of the GTs, as required to supply the thermal plants steam consumption.

The BPSTs operating on HRB steam will be sized so that their steam flows and backpressures match the requirements of the thermal desalination plant(s). They will be operated continuously, i.e. base-loaded.

The thermal desalination plant will be sized and designed to a GOR that maximises the benefits of cogeneration and hybridisation.

The SWRO plant will be combined with the thermal plant in the preferred hybrid scheme and sized to meet the balance of water demand, and, if possible, create the optimal SWRO to thermal plants output ratios in the range of 2:1 to 3:1.

The economic justifications for this scheme will be presented in Part 3 of this article series that will be published in the June 2003 issue of WWI.

Authors' noteDaniel Hoffman and Amnon Zfati of ADAN Technical & Economic Services Ltd., Tel Aviv, Israel, highlight the main points of their MEDRC-sponsored study in this three-part series published in WWI. Part 1 (WWI April) analysed the reasons for high desalinated water costs in Middle East countries' dual-purpose stations. The full study may be downloaded from MEDRC's web site: www.medrc.org.om, by clicking on "Research Program", then on "Final Reports", and, finally, on Project No. 97-AS-008a.