Ultrafiltration membranes offer alternative ways to comply with future discharge standards

Several ultrafiltration membrane processes offer engineers alternative ways to enhance or upgrade existing treatment systems to ensure effective and economical compliance with future discharge requirements. Jack Noble and Stuart Barefield of Zenon Environmental (UK) Limited explain the ways in which UF membrane processes are used to improve effluent quality.

Enhanced effluent quality requirements are being increasingly specified including lower BOD, suspended solids and ammonia concentrations in addition to improved phosphorus removal efficiency. To meet these challenges, ultrafiltration (UF) membranes can be used to upgrade conventional activated sludge (CAS) systems to enhance performance and throughput. They can also provide a tertiary process for treating a variety of final effluents. Additionally, new MBR applications can be installed in wastewater treatment projects.

The Zenon ZeeWeed® process is a patented low-pressure immersed membrane technology using hollow-fiber UF membranes operating in an outside-in flow direction. A vacuum of 0.2-0.3 bar is generated by permeate withdrawal pumps. In some applications, gravity withdrawal can be used providing site conditions allow sufficient differential head across the membrane.

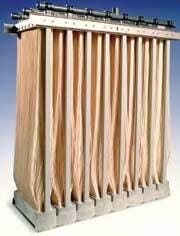

The membrane is chemical and oxidant resistant and tolerant of variations in pH, and it is compatible with powdered activated carbon and a variety of coagulants. With an absolute pore size of 0.1 µm, membranes are contained in bundles called modules, which are then assembled into cassettes. The cassettes are directly immersed in the medium to be separated. As permeate is withdrawn, solids are rejected at the membrane surface.

ZeeWeed membranes can be automatically backpulsed using collected permeate. The airflow generated by coarse bubble air diffusers, located at the base of each membrane cassette, scours the external membrane surface and removes the rejected solids. The airflow also supplements oxygen requirements in a biological system. The membrane air scour typically provides 30 percent to 50 percent of the total oxygen requirements in municipal MBR applications.

Two cassette designs, ZeeWeed® 500 and ZeeWeed® 1000, have been developed for high and low solids applications. The ZW500 membrane cassette operates with cyclic aeration, which lowers energy consumption and keeps air diffusers clear of sludge fouling. The ZW1000 cassette is only air scoured during an intermittent back pulse and cleaning cycle.

ZeeWeed 500 membranes use reinforced fibers to provide greater mechanical strength when used to separate permeate from mixed liquor suspended solids (MLSS) in MBR or high solids tertiary applications. ZeeWeed 1000 membranes are non-reinforced and are used in low solids separation processes such as in tertiary treatment. The packing density of the membranes reflects the application. ZeeWeed 500 cassettes have greater spacing between the modules to allow solids to be more easily removed from the fiber bundle.

Depending upon the nature of medium, the rejected solids are either returned back to the process (as in MBR applications) or displaced through the use of backpulsing (as typically in tertiary applications).

Zenon membrane cassettes are generally immersed in a separate tank from the bioreactor or process, resulting in a number of advantages including simplified construction when considering retrofit applications. Also, easier isolation of membranes is achieved for cleaning, and reduction of energy consumption at smaller sites is possible where periods of no flow may occur. Optimum conditions are achieved within separate biological treatment and solids separation stages, and reduction of costs is possible with existing structures retained or adapted.

Tolerance to solids loadings is conditional on filterability. In low solids filtration, coagulation or flocculation may be required depending on the nature of the process.

MBR upgrade enhances asset

New regulations are requiring wastewater treatment facilities to achieve lower concentrations of effluent nutrients, nitrogen, and phosphorus. Also, where the number of intermittent discharges is being rationalized within a water catchment, the hydraulic load on existing processes may be expected to increase.

An existing CAS process may be retrofitted with a membrane separation stage as a replacement of the existing clarification process. The membranes offer a physical barrier to suspended solids, which permits the process to be operated for maximum biological and hydraulic performance rather than settling conditions. As volumetric loading rates are high, systems are compact, which gives membrane technology a significant advantage in new locations where space is at a premium or increased capacity is required.

If phosphorus levels need to be reduced, coagulants may be added directly to the aeration process. The majority of phosphorus discharged from a CAS process is particulate. Effluent soluble phosphorus concentrations can be reduced to less than 0.05 mg/l through the aeration process, rather than prior to primary settlement, therefore reducing the quantity of primary sludge generated. Due to the small membrane pore size, the discharge of particulate material is virtually eliminated allowing for consistent achievement of < 0.1 mg/l effluent phosphorus. For larger systems, it may be economical to include biological phosphorus removal in the design.

The Zenon membrane can remove bacteria as well as most viruses at > 4 log removal. This capability has particular benefits for discharges at coastal locations.

Tertiary treatment of final effluent

The use of membrane systems for tertiary filtration of final effluent will ensure low solids and subsequent reduction of particulate BOD. Membrane filtration systems can be used for effluent polishing of most biological processes such as trickling filters or rotating biological contactors.

Whilst the ZeeWeed 500 would be used exclusively for high solids wastewater applications, the ZeeWeed 1000 is suitable for tertiary applications when the solids loading is consistently less than 30 mg/l.

Two basic alternatives for tertiary treatment in municipal applications are:

1. Solids removal: Removal of suspended solids has a significant effect on the concentration of associated BOD. Typically, tertiary membrane systems operate with recoveries between 90-95% depending on solids load and characteristics.

2. Phosphorus removal: When used with coagulation, the risk of coagulant floc carryover is minimized due to the physical barrier provided by the membranes. This opens possibilities for coagulant dosing after the biological process or reducing the initial coagulant dose prior to primary settlement.

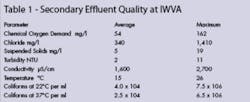

In 2002, at IWVA, the Belgian Intermunicipal Water Company of the Veurne Area, Zenon commissioned a membrane system that provides UF pre-treatment of municipal secondary effluent (see Table 1) prior to reverse osmosis (RO). Treated water from the RO is injected into the aquifer to act as a barrier to sea water contamination, and this provides a raw water source for potable use following an underground retention period of 40 days. The facility indirectly meets around 40 percent of the region’s drinking water needs, producing 2,500,000 m3/year.

Effluent is treated by a 1-mm pre-screen before chlorine dosing prior to storage in a reservoir. Chlorinated water then flows into the UF process tanks from where permeate is extracted from the membranes. The UF system is designed for a maximum flow of 450 m3/h. The facility consists of five UF trains, each with five ZW500 membrane cassettes.

Post-chlorination and ammonia dosing are used to form monochloramines prior to storage in the UF reservoir. Prior to RO treatment, dosing of anti-scalant, sulphuric acid and sodium bisulphite (for dechlorination) is undertaken before the UF permeate passes through 15 µm-rated cartridge filters.

RO permeate flows into the treated water reservoir where 90% RO permeate is blended with 10% UF filtrate. The blend is treated by UV prior to pumping into the ground. Extracted groundwater is treated by aeration and sand filtration.

New MBR systems

Membrane technology is becoming the preferred solution where the choice exists to install MBR systems in new wastewater treatment works. In May 2005, the first full-scale MBR system in the Netherlands began operating. The Varsseveld MBR project includes Zenon membranes. The project involved extensive on-site pilot studies over a five-year period. The selection of Zenon technology was based on results from the demonstration program and positive experiences with hollow fiber membranes in several Dutch treatment plants.

The Varsseveld plant was designed for 755 m3/h of wastewater projected in 2015, relating to 23,150 population equivalents. The design was based on stricter effluent requirements than stipulated by Dutch law: < 5 mg/l total nitrogen and < 0.15 mg/l total phosphorus. The design features needed to accommodate the presence of a nearby cheese factory and a maximum hydraulic load of three times the average supply due to high rain drainage.

Significant attention was paid to pre-treatment, with leaves and other components removed through a screen, an aerated sand and grease trap, and perforated microsieves. Membranes were installed in four separate compartments, specially designed to ensure uniform distribution of the wastewater loading. The division into compartments made it possible to take membranes out of service in case of low supply levels.

Conclusions

MBR systems have been successfully employed in the enhancement of biological processes, in making best use of existing equipment, and in new-build situations. A number of different scenarios are possible for upgrading CAS processes to nitrifying, de-nitrifying or phosphorous removal processes.

The use of UF membranes in tertiary applications can reliably produce effluents with minimal solids and particulate BOD. Coagulation may also be employed to reduce effluent phosphorus concentrations. The membrane acts as an effective barrier to particulates, ensuring that coagulant flocs are retained within the system. Footprint and land availability issues are minimized due to the compact nature of Zenon membrane systems.

Authors’ Note

Jack Noble is managing director and Stuart Barefield is sales manager at Zenon Environmental (UK) Limited. Contact Jennie Peace for further information at Zenon’s offices in Sheffield on +44 1226 760600 or email [email protected].