By Everett J. Nichols, Ph D

The complex challenges of stormwater treatment often create a financial and environmental catch-22 for construction and industrial companies, forcing them to choose between expensive and potentially ecologically harmful clean-up procedures or stiff penalties if they fail to meet state and federal regulations.

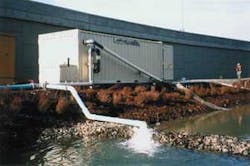

700,000 gallons of untreated water from a construction site settling pond was pumped through a sand filtration process and into a holding pond using Storm-Klear Liqui-Floc to remove fine sediment, phosphorus, oil and minerals. The water was then safe for release into public water sources.

Recent recognition of a new water treatment technology, chitosan-enhanced sand filtration (CESF), by the Washington State Department of Ecology (Ecology) eliminates this difficult decision by offering a cost-effective and environmentally sound solution for contractors in the US state of Washington, and shows promise for applications in many countries.

In October 2003, CESF, which uses chitosan-based water clarifier Storm-Klear™ Liqui-Floc™, became the first technology to meet stringent new environmental regulations and receive conditional-use designation from Ecology. This regulatory milestone opens the door for companies to use CESF technology for stormwater treatment and enables them to meet or exceed Washington state water quality standards using an environmentally friendly system.

A high level of state and local enforcement and Washington's culture of environmental preservation make it a challenge to gain approval for stormwater treatment systems. In October 2002, Ecology created its Chemical Technology Assessment Protocol, a new programme to determine the efficacy and toxicity impact, with an eye toward salmon and other wildlife, of commercial water treatment methods used by contractors and industrial companies.

To earn Ecology approval, Natural Site Solutions, the exclusive distributor of Vanson HaloSource's Storm-Klear products and creator of the CESF process, completed a series of tests using state and federal Environmental Protection Agency (EPA) protocols to measure the impact of the technology on aquatic organisms, with particular attention to endangered salmon species, and to validate claims of treatment effectiveness.

According to the Ecology report, CESF technology used in tandem with Storm-Klear is unique among water treatment methods for being virtually non-toxic to humans and other mammals, and when used in properly engineered water treatment systems, poses no threat to fish and aquatic organisms.

Not only is stormwater filtration crucial in the effort to protect and preserve aquatic species, it is also essential for public safety purposes. Water that runs through these construction sites is released into public outlets, including sanitary and storm sewers and surface waters.

"Washington has the most stringent water quality standards in the United States and other state ecology departments look to it for leadership in the stormwater management arena," said Sean Manne, marketing director at Vanson HaloSource, the manufacturer of Storm-Klear. "Ecology's acknowledgement of CESF used with Storm-Klear not only underscores the efficacy and safety of the system, it opens the door for companies throughout the United States to begin employing this technology as a feasible storm water management tool."

Karl Bruegeman, president of Natural Site Solutions commented, "Prior to this regulatory recognition, companies have had limited options in the stormwater arena: purify water incompletely and undertake expensive clean-up operations, or pay exorbitant penalties. Contractors now have a natural, cost-effective alternative."

Prior to CESF technology, the primary alternatives were basic sand filtration; moderately effective erosion control measures, which employ artificial barriers, such as plastic or straw to trap sediment; water transport to treatment facilities or holding tanks; or discharge into sanitary sewer systems, which is very costly.

Basic sand filtration operates on a series of pods filled with layers of rock and sand. Water is pumped through vessels and with the assistance of a flocculant, the rock and sand barriers capture contaminants while pumps carry the treated water back into the water source.

Before the introduction of chitosan into sand filtration, companies had limited flocculant options — polyacrylamide and other synthetic, petroleum-based products that raised environ- mental concerns about potential toxicity and long-term impact.

Although sand filtration itself is not a new technology, incorporating chitosan significantly improves filtration results. According to Vanson HaloSource, CESF with Storm-Klear Liqui-Floc outperforms traditional sand filtration by enhancing the system's ability to remove suspended solids, some heavy metals, and other pollutants from stormwater runoff.

Clear Water Compliance Services of Lynnwood, Washington, used the CESF treatment system at a resort on a high-risk site, where the contractor had to prevent stormwater runoff from flowing into Hood Canal.

By forming long chains of molecules with cationic, or positive charges, chitosan acts like a hook to bind particles and floc negatively charged organic and inorganic materials, such as clays and other contaminants suspended in water. In addition to sand filtration, the process increases the effectiveness of other traditional treatment methods, including gravity settling tanks, biofiltration, cartridge filtration, or pond re-circulation, at removing contaminants.

CESF enables companies to work year-round, which results in significant time and cost savings. During major construction projects, contractors can face a host of fines and work is often delayed or shut down because site water runoff does not meet environmental standards.

CESF with Storm-Klear has been used on construction projects throughout the Northwest, including the 2001 cleanup of toxic substances at Cascade Pole Company's wood-treatment facility at the Port of Olympia, Washington. Studies showed that the technology removed 99% of suspended sediments, and dramatically reduced other pollutants of concern, producing water clean enough to be discharged directly back into Puget Sound.

Polynuclear aromatic hydrocarbons (PAHs), petachlorophenol (PCP), volatile hydrocarbons and dioxins were among the toxic substances found in the soil, groundwater, surface water, intertidal sediments, and marine organisms at this site. Some 40,000 cubic yards of contaminated sediments were removed and stored in a containment cell on the upland Cascade Pole site, and will eventually be capped. Contaminated dredge water and sediment dewatering was directed to a temporary holding pond and treated to remove PCP, total suspended solids (TSS) and turbidity.

One common water treatment methodology to remove PCP, TSS and turbidity involves three basic steps:

• Gravity settling for solid-liquid separation;

• Particulate filtration for suspended particle removal;

• Carbon absorption for organic contaminant removal.

The overall effectiveness of this approach is largely dependent on the ability of the treatment system to remove suspended fine particulate (colloidal particles). In most cases, a portion of the total concentration of the organic pollutants within water is bound to the surface of colloidal particles. In addition, colloidal particle removal improves the efficiency of carbon absorption units. Since treated water at the Cascade Pole site was to discharge into Bud Inlet and not a sanitary sewer system, Ecology required the complete removal of all pollutants of concern.

To comply with Ecology regulations, the site remediation contractor implemented Storm-Klear products to enhance sediment and turbidity removal in the gravity settling and filtration portion of the water treatment system. Removal of these constituents also reduced levels of PCP and other organic compounds associated with suspended particles allowing the carbon absorption unit to operate at peak efficiency.

Storm-Klear Gel-Floc was deployed inline between the stormwater collection pond and the treatment system settling tanks. The Gel-Floc dissolves when water is passed over it, releasing a micro-quantity into the water, which coagulates fine suspended particles. Coagulation makes suspended particles much larger and denser, resulting in accelerated settling rates. The addition of Gel-Floc enhanced the gravity-settling process and reduced turbidity by more than 90%.

Settled stormwater was treated with an inline injection of Storm-Klear Liqui-Floc to coagulate suspended particles as it was transferred from the settling tanks to a sand filtration unit. Once coagulated, the suspended particles can be removed with sand filtration. The Liqui-Floc treatment enhanced the sand filtration system's TSS and turbidity removal efficiency by more than 99%.

Larry Darnell of Lakeside Develop-ment in Redmond, Washington, has used CESF with Storm-Klear on his 90-acre residential development complex for two years. "It's been nothing short of phenomenal," Darnell said. "Lakeside Development was in a high-risk location, adjacent to a sensitive wetland, so I was under intense scrutiny from state and local regulators. CESF enabled me to continue working in the wet season, which saved me hundreds of thousands of dollars over the course of the project."

Prior to the Ecology announcement, select job sites throughout the county used the system through a special permitting process. State tests illustrated the technology's viability in the field and after an additional round of field tests, CESF with Storm-Klear will be considered for general-use designation.

Author's NoteEverett J. Nichols, Ph.D., M.S.P.H., is the vice president of research and development for Vanson HaloSource, based in Redmond, Washington, USA. One of the foremost authorities on chitin and chitosan, Dr. Nichols has spent 23 years studying the structural and functional properties of biological carbohydrate biopolymers, including chitin and chitosan.

Vanson HaloSource employs bioscience technologies to create solutions for customers in water treatment and purification, biomedical, healthcare, manufacturing and consumer markets. Visit www.vanson.com for more information.