Mexico Pumps Down the Pressure

Two large combined wastewater pump stations fitted with high-performance submersible motor pumps are to provide relief for hundreds of thousands of people in Mexico City from the dangers of flooding during the rainy season. Jens Mielke explains how this project forms part of the millennium infrastructure project in the Mexico City Valley.

The Mexico City Valley is experiencing increased population growth and rapid urbanization, creating a constant rise in demands for water supply and sanitation provision. This demand has been largely met by an enlarging system of wells drilled into the soft aquifer beneath the region. This intense exploitation has resulted in a significant lowering of the ground — up to 50 cm/year in some areas.

In addition, spreading urbanisation is causing a loss of forests in the surrounding mountains, leading to decreasing rates of storm water percolation, as well as ever rising amounts of wastewater that need to be handled. Soil subsidence and storm water surges are threatening to make the existing infrastructure collapse and cause flooding after heavy rainfalls.

The National Water Commission CONAGUA is combating the devastating consequences by implementing a number of major infrastructure upgrade measures. The pump station La Caldera forms an essential part of the deep tunnel project which will help to avoid floods in the eastern part of Mexico City Valley.

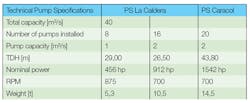

Inaugurated by President Felipe Calderón Hinojosa, the pumping station is lifting the waste and storm water arriving through a huge tunnel some 30m below the surface and discharging into an open drainage channel. The pumping plant itself basically consists of one sump in which mechanical screens are installed and two sumps, each accommodating 12 KSB KRT Series pumps, inside a 20m diameter cylinder and around 35m deep. The pumping station is designed to handle a total flowrate of 40 cubic metres per second (m³/s).

A similar design concept has been applied to a second pump station, which is presently under construction. Called the Caracol pump station, it is being constructed in the federal zone of the Lake Texcoco and is projected to discharge 40m³/s combined sewage from the Emisor Oriente Tunnel to the Gran Canal open sewer channel. In total, 20 Series submersible pumps will lift the fluid more than 43m in height.

In the La Caldera plant each of the eight KSB Amarex KRT submersible motor pumps (four pumps per sump) have a flow of 1m³/s of municipal sewage, totaling the 8 m³/s which the system designers consider being the maximum dry weather flow. The remaining 16 pumps, each with a capacity of 2 m³/s, are designed to come into operation during storm water conditions, raising the total pump capacity up to a 40m³/s. In the Caracol pump station each of the 20 pumps is capable of pumping 2m³/s. The dry weather flow will be handled by four pumps per sump, with 12 pumps taking care of peak flows during rainy season.

When it came to the pump design, KSB's engineers faced a couple of challenges. The huge medium voltage motors had to develop up to 1600 hp — one of the highest nominal powers KSB had ever built - while still fitting into the general series design concept.

Moreover, the standard guide system for lowering and lifting the pumps in and out of the sump had to be adapted to site conditions. The solution devised was a device that allows automatic connection/disconnection of the lifting crane hook from the pump motor unit.

The biggest challenge though was to find a sump design that would allow the end user to operate the both plants in an efficient and reliable way. KSB was contracted to prepare a design that would fit the given dimensions and optimize this using computational fluid dynamic (CFD) simulations as well as a physical model test.

The overall aim was to reduce the energy of the incoming flow and to provide the pumps with favorable suction conditions. The flow had to approach to each pump with limited and equally distributed velocities and be free of pre-swirls. Surface as well as submerged vortices could not occur in any part of the sump and air entrainment had to be avoided by any means possible.

Furthermore, several specific wastewater issues had to be observed. These included flow velocities, which could not fall below a certain value in order to prevent sedimentation of the solid parts in the pumped medium; no dead zones were desired. All this had to be combined with the demand for separation between dry weather and storm weather pumps.

Numerical flow simulation/CFD is an important and effective instrument that allows relatively precise predictions of the flow conditions. Figure 1 shows the optimized pump station designs elaborated through multiple simulation turns. In both pumping stations the incoming flow will lose much of its energy in a pre-chamber, from where the flow is directed to the dry weather pumps. By starting from a certain water level, the incoming flow can spill over to the rain weather sump section. The heavier polluted wastewater stream will therefore remain in the dry weather part of the sump and will not enter the whole sump.

A protective wall guarantees that approaching velocities remain in acceptable limits (in respect of absolute values as well as distribution profiles close to the pump´s suction inlets). This is despite the fact that 20m³/s mean a huge amount of kinetic energy.

On the other hand it was achievable to maintain reasonable velocities close to the sump bottom even during low flow periods, which is important in view of undesirable build-up of sediments in the sump. Dead zones could be completely eliminated.

Additional design features included preventing pumps influencing themselves and preventing the formation of air entraining surface vortices. The design that was found to be most suitable after CFD simulation was then converted to a geometrically corresponding scale model made of transparent materials and tested in the a hydraulic laboratory.

Using the observations made possible by the model, engineers could verify if the concept they had elaborated in the computer model really worked out as it was supposed to.

In fact a physical model test still is the most reliable instrument to identify precisely where particular problematic conditions might arise and how to tackle these. To judge vortex development for example, the fluid surface as well as walls and floor areas are observed. Vortex intensity in a given is revealed by means of dyes that are injected into certain sump areas.

The flow velocities are measured at reference points across the model's entire suction cross section via Pitot tube. Mean flow velocities should not deviate more than 10% from pre-defined values. The pre-swirl angle with which the suction flow approaches the pump is measured by a vortometer. Variations of +/- 5º are acceptable.

The application of dimensionless coefficients enable the engineers to transfer the results to the full-size structure. However, events that have a minor effect in the model may be considerably more significant in the full-scale structure.

The pumps supplied to the La Caldera pumping station showed excellent performance during field tests and have been working satisfactory since March 2010.

The Caracol pumping station will be commissioned in spring 2012 and KSB's engineers are convinced that the pump station design and pump performance will meet client's expectations.

Author's note: Jens Mielke is from KSB's department for wastewater applications. For more information, please email: [email protected].

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles