Worms offer sustainable waste processing solution

Dr. Jörg Hardege

A pilot scheme demonstrates the capability of worm bioreactors to reduce solid waste volume up to 60 percent and decrease toxicity up to 90 percent.

The Environmental Technologies Centre for Industrial Collaboration (ETCIC) is harnessing a natural phenomenon hidden in estuaries - a ragworm that thrives on liquid organic waste such as sewage sludge. A test programme piloted in collaboration with the UK company Yorkshire Water demonstrated incredible results using a “worm bioreactor” at the company’s sewage treatment works.

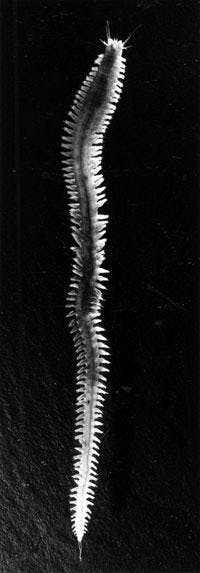

The worm bioreactor relies on the digestive properties of a common ragworm, known as Neresis diversicolor, and is the brainchild of the ETCIC biological science research group at Hull University. The group spotted the worms’ potential when studying their natural presence in estuaries. The worms’ abundance and size increased astonishingly the closer they were to sewage outfalls in comparison to so-called “clean environments.”

Taking the worms into the laboratory, the group quickly discovered that these worms not only survived such stressful conditions, but they also significantly reduced the quantities of organic material and reduced toxicity. The group has spent almost 10 years researching the worms’ culture, growth, microbiology of pathogens, eco-toxicology and potential capacity of dealing with a variety of food sources ranging from aquaculture sludge in eel farms to sewage.

Once revealing the unique capabilities of the worms, the group decided to replicate optimal conditions by developing a special bioreactor to treat sewage sludge and other liquid organic wastes. Working alongside Yorkshire Water, the group erected a pilot plant consisting of three tanks of two to three square meters at Bridlington sewage works. Sand beds with a lining and drainage system were established in the tanks and brackish water of a salinity of eight to ten percent used. Water was circulated and sprinkled over the worm bed (for aeration) and fresh surplus sludge applied with the recycled water.

Layers of gravel and sand allowed percolation and enabled the ragworms to dig dwelling tubes from which they initially filtered suspended particles by spinning a mucus net in front of the tube. Pumping water through the net, the worms actively aerated the surrounding soil. In addition to organic sewage bulk, the worms offered further benefits by digesting bacteria (E. coli, coliforms, enterecocci), cysts of parasites (Giardia, Chryptosporidia) and eggs of round worms. Digested bacteria biomass was defecated, increasing the soil level of the sand bed, then once all the suspended material was filtered, the ragworms switched to surface grazing. This process was repeated as the worms worked through the waste.

Sewage sludge with high content of bacteria and organic material is an excellent food for ragworms and at a density of 3,000 worms per m2. Water that contains organic particles was filtered at an incredible rate of 9.8-13.5 m3 per square meter of worms per day. Worm densities in the pilot bioreactor system are typically around 10,000 per m2, resulting in the ingestion of waste mass (dry weight) at 80 to 144 kg m-2 p.a.

The pilot scheme has demonstrated that the worm bioreactor can reduce solid waste volume up to 60 percent and decrease toxicity up to 90 percent. A further bonus is that the system actually generates, as a by-product, near pure water that can be recirculated. While the initial pilot programme has revealed dramatic results, the research group is already working on modifications that will bring an even greater level of optimisation.

Initial data from the two-year trials show that the process is inexpensive and sustainable. It requires low energy unlike conventional systems, and offers water companies an alternative to incineration and landfill with waste being made less toxic and the waste volume dramatically reduced. The system can be used at a local community level in addition to having potential applications in larger centralised, processing facilities making it attractive for small treatment works or enterprises and potentially also for land-based aquaculture. Capital expenses for companies to establish the worm bioreactor are also conservative compared to a conventional plant. In terms of technical expertise requirements, the main input would be from biological engineers in order to oversee the plant’s biological conditions such as oxygen and water flow.

Following the success of the pilot scheme, ETCIC plans to demonstrate the potential of the approach in full-scale applications for treatment of sewage and animal wastes of liquid state. It seeks to develop working relationships with other organisations as part of the way forward to join a team of international experts in the UK, Germany, Spain, and Portugal, who are keen to further develop the technique for commercial use.

Author’s Note

Dr. Jörg Hardege is head of the Biological Sciences Department at Hull University, UK, and works at the Environmental Technologies Centre for Industrial Collaboration. The ETCIC is funded by Yorkshire Forward as part of its network of Centres of Industrial Collaboration, and is managed by The University of Hull under the supervision of Prof. Lynne Frostick. Email: [email protected]@hull.ac.uk. Web: www.etcic.com.