In recent years, a growing number of water utilities have installed fuel cell technology at water and wastewater treatment facilities. So, how does the technology work? What are the key technological and operational advantages, as well as the financial benefits? Andrew Williams investigates.

Scottish Water has recently installed fuel cell technology at several drinking water storage sites on the Isle of Lewis, in the northern part of Lewis and Harris, the largest island of the Outer Hebrides of Scotland.

As a result of the facility's remote location, the utility had found it difficult to secure a reliable source of power to ensure its telemetry equipment, which provides accurate data for recording the levels of drinking water contained in the tanks, remained fully functional at all times.

In previous years, extremely high winds had dislodged solar photovoltaic (PV) panels and caused wind turbines to either burn out or seize up - and the isolated location of each 50 m3 water storage tank, located on the side of mountains at Meavaig and Marivaig, meant that connecting to the National Grid for electrical power was not financially viable.

After discussions with UK-based company Fuel Cell Systems, Scottish Water finally decided that fuel cell technology was the most suitable alternative source of portable power to ensure the 18,500 islanders were provided with a constant supply of drinking water.

Technology explained

As Tom Sperrey, CEO of Fuel Cell Systems, explains, there are two main groups of fuel cell technologies, high and low temperature.

High temperature technology is mainly used for larger applications, while lower temperature technologies, such as Proton Exchange Membrane (PEM) fuel cells and Direct Methanol fuel cells (DMFCs), tend to be used for smaller scale projects.

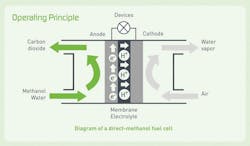

Lower-temperature fuel cells work by ionising a hydrogen-rich fuel by passed it though a semi-permeable membrane, and combining it with oxygen to create pure water - and to provide a flow of free electrons between an anode and cathode - producing an electrical current. This process creates a small voltage of around one volt - which can be easily increased by 'stacking' membranes alongside or above one another.

Sperrey says that, with DMFC systems, the company has achieved an output of 2.5kW 'quite comfortably' and with PEMs up to 200kW. However, beyond these levels high temperature systems would typically be used.

A key application of low temperature technologies is as a source of standby electrical power – and the company turned to these for the Isle of Lewis project, as well as for other similar schemes at Severn Trent and Dwr Cymru Welsh Water sites.

In applications of this type, the system works by continuously monitoring battery voltage - and as soon as the load has reduced the voltage to a pre-set figure, typically around 12.2V, the fuel cell automatically starts re-charging the battery to 14.4V, before shutting down again.

The Lewis project uses Direct Methanol (DMFC) technology. Here, Hydrogen-rich Methanol is mixed with water - produced as a result of the reaction in the fuel cell - and reacts at both the anode and the cathode side of the cell. This reaction produces more water, which is largely re-used, a small amount of CO2 - which Sperrey says is often described as 'equivalent to that in a baby's breath' - as well as heat and electricity. In simple chemical terms, the combined two-stage reaction is: CH3OH + 3/2O2 -> 2H2O + CO2.

"The small amount of condensate that is produced is pure water and is drained off to ground, not being in large enough volumes to justify capture. All of our water company customers to date have, after initial trials, integrated the fuel cell's digital status outputs into their own data capture systems," says Sperrey.

In Sperrey's view, when utilities decide to embark on fuel cell installations of this type, the savings realised are primarily related to saved manpower and transport mileage as a result of not having to replace discharged batteries on a regular basis. With current models, he says that a fuel cell system can provide up to 124 kilowatt-hours (kWh) of continuous power between visits.

"When you consider that a 12V 100AH battery with a typical lower discharge limit of 50% provides only 0.6kWh of autonomy, you can begin to see how amazing savings can be made," he says.

As well as the financial savings gained from a vastly reduced recharge and refuel schedule, Sperrey also points out that there are "obvious" carbon savings as a result of the much reduced mileage involved in supporting remote sites.

"If you start to add in the administration support behind the 'man in the van' it really builds up enormous savings," he adds.

Moreover, because fuel cells use a chemical process rather than moving parts, Sperrey highlights the fact that their servicing requirements are low - and adds that they also make "very efficient" use of fuel.

"Diesel generators are at best 30% efficient, but PEM fuel cells are 60% efficient," he says. "They are also very quiet, which generators generally are not, and do not require a great deal of additional infrastructure to install."

In other developments, both Bristol Water and United Utilities are also currently implementing a pilot system using the technology - and Sperrey is keen to stress that Fuel Cell Systems are now in discussion "with the majority of the UK's water companies."

"Meanwhile, the Environment Agency, having rolled out a couple of projects with us, has recently carried out a board-level presentation of our technology and has plans for much wider implementation in the coming months," he adds.

Fuel cells in Orange County

Meanwhile, another fuel cell technology project, this time at a wastewater treatment plant in the US, has also resulted in a number of key benefits.

The scheme was established at the Inland Empire Utilities Agency's (IEUA) RP-1 wastewater treatment facility in Ontario, California - which is designed to treat some 44 million gallons of wastewater per day. The facility uses anaerobic digestion to treat the biosolids from the wastewater process, which produces renewable digester gas that can be used to generate combined heat and power on site.

According to Jesse Pompa, environmental compliance officer at Inland Empire Utilities Agency, the facility had previously operated co-generation engines to combust the digester gas but, in 2008, IEUA evaluated potential alternatives that could produce renewable energy while also helping to reduce process emissions.

The Agency developed a Request for Proposals and selected Ontario, Canada based anaerobic digestion company Anaergia to install and operate a 2.8-megawatt fuel cell that uses biogas as its main fuel source.

"Although the technology has previously been employed at other treatment plants, the RP-1 fuel cell is the largest fuel cell operated on biogas in the country," says Pompa.

The unit is a molten carbonate fuel cell that reacts with the methane in the digester gas to generate electricity and heat, with water - in the form of steam - and carbon dioxide as the main reaction products.

Before being introduced to the fuel cell, the biogas is sent from the anaerobic digesters to a three stage gas conditioning system that is designed to remove hydrogen sulphide, siloxanes, and Volatile Organic Compounds (VOC) from the gas, all of which Pompa says "pose potential threats to the fuel cell catalyst".

The RP-1 fuel cell is part of a Power Purchase Agreement (PPA), whereby Anaergia owns and operates the equipment while IEUA hosts the unit on site and purchases all of the electricity that is generated at an agreed contracted price.

As Pompa explains, the agreement "has a 20-year duration with low fixed annual escalation to compete with grid pricing". For him, a key benefit of this PPA structure is that it contributes "inherent risk mitigation" for IEUA, since the amount of revenue that Anaergia receives "is tied to the run time and efficiency of the equipment".

He adds: "Moreover, Anaergia is the sole point of contact for both the fuel cell and gas conditioning system, so any equipment deficiencies or breakdowns are managed swiftly under one roof."

In Pompa's view, the financial benefits are "a little difficult to predict" because IEUA is still only in the first year of the 20-year agreement. He does stress that the electricity purchase price is competitive with current electrical utility costs.

Since the fuel cell PPA contract has a fixed escalation rate of 2.5%, and IEUA's local utility has historically increased fees at a rate of approximately 6%, he points out that IEUA "is confident that the PPA price will drop below grid pricing in short order".

"In addition, the fuel cell's baseload operation allows for reduced reliance on the grid during peak periods, when utility tariffs are highest - which increases cost savings. The fuel cell's heat recovery process results in further savings achieved from reduced natural gas usage that would be needed to generate heat for the anaerobic digestion process," he says.

"While the actual financial savings will be dependent on future utility costs, forecasting grid pricing at the historical average would save IEUA approximately $21 million in electricity costs over the life of the 20-year agreement," he adds.

Pompa has no hesitation in recommending projects of this type to other utilities. He stresses the fact that IEUA has found that the PPA structure "not only reduces the risk involved in this type of technology, but reduces the significant capital and ongoing maintenance costs that often serve as a roadblock to implementing a project of this magnitude".

However, he points out that the establishment of a public-private partnership was "essential" in successfully developing and executing the project - as well as in "creating the economic blueprint to ensure long-term financial benefits for both parties".

In total, IEUA operates four wastewater treatment facilities within a service area of approximately 240 square miles. According to Pompa, only two of these facilities treat biosolids through anaerobic digestion, so his view is that the Agency's opportunities for another fuel cell project of this type are "limited".

"The technology is subject to economies of scale, so there are several factors that the Agency will need to consider before determining whether a similar project can be undertaken at another treatment plant," he says.

Microbial Fuel Cell Research

In another development, a research team at Oregon State University is developing a microbial fuel cell (MFC) that uses microorganisms to break down organic matter and generate electricity simultaneously.

As Hong Liu, associate professor at the Department of Biological and Ecological Engineering, Oregon State University, explains, the approach has emerged as a potential clean technology to harvest energy from wastewater. He expects that it will eventually replace existing biological treatment processes, such as activated sludge, trickling filter and anaerobic bioreactors in wastewater treatment systems across the globe.

"The electricity generated can reduce the energy cost and enhance the sustainability of wastewater treatment," says Liu.

According to the associate professor, the treatment of organic-rich wastewater currently consumes about 3% of all electrical power produced in the US.

In his view, capturing a part of the energy stored in wastewater would provide a new source of electrical power "that would also avoid the consumption of energy for wastewater treatment".

For Liu, a key benefit of the new approach for utilities is the fact that it consumes less energy - with a possible net energy gain - than activated sludge processes. He also points out that "less sludge is generated" than during activated sludge processes - and that there is a faster Biological Oxygen Demand (BOD) removal rate than "typical anaerobic processes".

"We are developing an MFC based decentralized wastewater treatment system [and] are working on a pilot project locally and hoping to get some preliminary results by next year," he says.

Andrew Williams is a freelance contributor to WWi magazine. For more information on this article, please email: [email protected].