In an effort to tap into the enormous potential of osmotic power, two innovative European pilot plants are currently in the pipeline in Norway and Italy. With biofouling and membrane performance cited as challenges to commercialising this technology, how are these projects progressing? Andrew Williams reports.

In the quest to reduce carbon emissions, osmotic power is beginning to emerge as a very promising new source of clean renewable energy. According to the Norwegian Centre for Renewable Energy (SFFE), the total global potential for osmotic power has been calculated as laying somewhere in the region of 1370 TWh per year - equivalent to the annual electricity consumption of 520 million people.

Salt and Shake

At its most basic, osmotic power is generated by the extraction of 'useful' energy (mostly in the form of electricity) from the differences in salt concentration of two separate solutions. The most obvious example is when a river empties into the sea - mixing large quantities of fresh and salt water and releasing energy in the form of heat.

According to Friso Sikkema, senior specialist in power generation and renewables at DNV Kema, the amount of potential energy contained in such processes is 'substantial'. The osmotic energy contained in 1 m³ of seawater amounts to around 0.75 kWh.

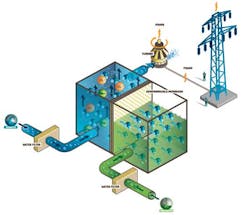

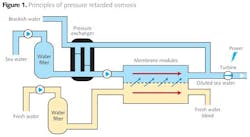

There are several ways to capture osmotic power. The two most successful approaches are pressure retarded osmosis (PRO) and reverse electrodialysis (RED). In PRO, which can be regarded as the opposite of Reverse Osmosis (RO), low salinity water is allowed to permeate through membranes into a higher salinity solution, pressurizing it in the process - and generating power when this pressure is released through a turbine.

"Using special valves and thick rubber sheets, the pressure exchanger allows the use of the pressure - which is built up in the membrane module. Otherwise, the brackish water would just flow away, releasing its pressure into the surroundings," says Sikkema.

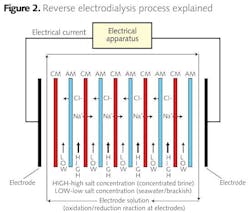

Meanwhile, in RED based processes, the ions contained in the water, and not the water itself, move from salty to less salty water - in the process creating an electrical current. As Sikkema explains, the RED method of generating osmotic power is "more counterintuitive" than PRO.

"It uses the same salt concentration difference as PRO but it uses the migration of charged ions instead of water to extract electrical energy directly from the solutions," he says.

In RED processes, cation and anion conductive membranes are placed in an alternating layers in order to produce diluate and concentrate compartments. The combination of a cation conductive membrane (CM), an anion conductive membrane (AM) and the two corresponding compartments is called a cell pair. The concentrate compartment (HIGH) is then filled with the high concentration salt solution while the diluate compartment (LOW) is filled with the low concentration salt solution. The salt concentration difference, or salt gradient, between both compartments in the cell pair invokes an electrochemical potential across the cell pair. In turn this causes an electrical current to flow through the electrical load connected to the electrodes.

Scaling up the Sunndalsøra Pilot Plant

Norwegian energy company Statkraft has been developing osmotic power, based on the PRO method, for more than a decade. In 2009 the firm started operation of the world's first osmotic power prototype. The facility, located on the premises of the Södra Cell cellulose factory at Tofte in Hurum on the remote southern coast of Norway, is also used for the testing of components, processes and membranes.

As Stein Erik Skilhagen, head of osmotic power at Statkraft explains, the prototype process "combines 10 litres of fresh water and 20 litres of salt water per second". At present, he says the facility is only capable of attaining a modest power output of between 2-4 kW, but with 'better membranes' he claims the power output can be increased to about 10 kW.

The prototype is based on six racks, each consisting of a total of eleven parallel pressure vessels containing specially designed spiral wound membrane elements. In order to ensure a steady supply of clean fresh water, the facility also features a pre-treatment plant, which filters water through a series of membranes made from cellulose acetate. Meanwhile, seawater is drawn through a series of water pipes placed just outside the local harbour.

Statkraft says that the installation of the membrane treatment plant for the fresh water has turned out to be "very useful" for testing various types of cleaning recipes - both for facilitating the operation of the plant itself, but also for finding new alternative ways to clean the PRO membranes.

The company's experiences at the Tofte plant have enabled it to prove the viability of the PRO process, as well as to carry out ongoing improvements to the technology. Following the favourable results at the prototype facility, the company announced in February 2013 that it intends to co-operate with leading Israel-based desalination company IDE Technologies in the construction of a 2 mega-watt pilot osmotic power plant in Sunndalsøra at the mouth of the river Driva in western Norway.

According to Skilhagen, the Sunndalsøra pilot plant will represent a 'significant step' on the road towards scaling up the technology, as well as for the involvement of 'leading suppliers.'

"The construction of the facility will entail the installation of some 400,000 m2 of osmotic power membranes, in addition to the related processes and systems," he says. "The reasons for choosing Sunndalsøra are at least threefold. The water quality available is very good, the site is already dedicated to osmotic power development and Statkraft have a large hydro power plant - Aura - next to the site," he adds.

Under the agreement, the Israeli outfit will use its desalination expertise to design, and later purchase and construct, the pilot plant - including a planned energy recovery system and fresh water and seawater pre-treatment facility.

Blue Energy Initiative

Elsewhere, the Blue Energy Initiative, consisting of a consortium of organisations, including DNV Kema and REAPower, and led by German company WIP Renewable Energies, is currently developing an osmotic power pilot plant, based on an innovative variant of the RED process, in Trapani, Italy.

"We are currently working to realize a pilot plant of the RED variant in Italy, using more energy dense brine - a highly concentrated saline solution - and seawater as the sources," says Sikkema, who is the project leader for the DNV KEMA part of the Trapani plant.

The technology under development is aimed at the production of osmotic energy by using a combination of two salt solutions with large differences in salt concentration - in a process called Salinity Gradient Power - Reverse Electrodialysis (SGP-RE). As Sikkema explains, previous SGP research has been primarily based on techniques that combine fresh water and seawater - but he points out that this approach has "important disadvantages", mainly because the low salinity fresh water increases the levels of electrical resistance.

As an alternative, one of the main objectives of the Trapani pilot plant team is to prove the concept of SGP-RE based energy production by using brine and sea, or brackish, water - as well as to develop the "necessary materials, components and processes".

"This is an exceptionally clean technology, which is still challenging to commercialize with current state of the art materials. However, it possesses enormous potential when material developments come through," says Sikkema. "The pilot plant will be the first of its kind. We are currently in the designing and definition stage, where we define things like how large the ducts and the stack must be," he adds.

Also during this stage, the consortium will work on optimising materials and components designed to enable SGP-RE technology operating with high salinity brine and seawater. This is as well as develop and verify a simulation model based on a series of tests on stacks in the laboratory. Sikkema says the team members will also 'evaluate and improve the performance of the overall system' via tests on a prototype system using real brine from a salt pond.

Based on the assumption of conditions similar to those found in this salt pond, where the first RE stack for brine and seawater reverse electrodialysis will be installed, Sikkema says that the consortium has calculated a theoretical osmotic energy content of 18.8 MJ/m3 of brine - which could result in a power output of 450 kWe.

The Scaling Up Challenge

Although the existing prototype facilities provide growing evidence that osmotic power has a great deal of potential as a future source of renewable energy, the general consensus is that a number of hurdles still need to be overcome before it can become a viable commercial proposition.

In moving towards this goal, Skilhagen believes that the involvement of large technology manufacturers will be "critical", particularly in relation to the development of "good and cost-efficient technology". He also stresses the importance of ensuring that the commercial opportunities and challenges in osmotic power are 'well communicated' and that the challenges are prioritized and resolved in the 'right order.'

"First we started with the membrane technology, then pre-treatment for fresh water and seawater and currently there are activities also to further improve technology for energy recovery to suit the needs in osmotic power," he says.

According to osmotic power expert Prof. Bruce Logan, director of the Hydrogen Energy (H2E) Center & Engineering Energy & Environmental Institute (E3I) at Penn State University in the US, it is also likely that a number of technological and process improvements will need to be made before commercial scale-up is possible.

To begin with, he explains that there is a pressing need for the design and development of "inexpensive and efficient" membranes. He also warns that the problems of fouling from biofouling, or the growth of microbes on the membranes, needs to be avoided.

"Anytime you put a material in water it would grow a biofilm. So you need to pre-treat the water to remove organic matter and microbes as much as possible," says Logan.

Sikkema agrees that biofouling and membrane performance are listed among "several problems" faced in the commercialization of both PRO and RED osmotic power technologies. In addition, he highlights the fact that several "general design issues" – such as stack layout, problems with leakage and shunt current control "have not yet been finished".

"The membranes for both technologies are not yet fully developed [and] the full prices for the membranes cannot be too high for economical reasons," he says. "The large quantities of water that enter the membrane module must [also] be purified to a certain extent - otherwise the membranes will quickly foul up."

Future Prospects

Looking ahead, DNV Kema's Sikkema believes that there is a "huge theoretical potential" for the development of osmotic power - across both Europe and the wider world. In the future, he estimates that up to 15% of all European electrical energy could be made 'using osmotic power across the globe.'

"The challenge is, as with all types of renewable energy, the low energy concentration. It is unclear at this point how fast this technology will develop," he says.

In terms of the areas that might be most promising for development, any country with a coastline can theoretically exploit the opportunity of producing green energy generated with osmotic power at locations where rivers meet the sea. Logan's view is that, in addition to the existing locations along the fjords of Norway and in Italy, larger-scale growth will "probably be restricted in the immediate future to where there is high water flow into the ocean, so for example in the Netherlands".

Although still at a very early stage of development, it is difficult to deny that high profile investments like the joint Statkraft - IDE Technologies and the REAPower Blue Energy Initiative point to growing confidence in the technology. Skilhagen for one, is upbeat about future market prospects.

"In regards to the future of osmotic power, it will definitely be a commercial and competitive part of the renewable energy mix," he says.

Author's note: Andrew Williams is a freelance correspondent for WWi magazine. For more information, please email: [email protected].