by Mark B. Miller

The need to develop a practical and sustainable approach to water management is rapidly becoming a priority in many communities. Global economic growth and population pressures have driven water usage to unprecedented levels. Recent droughts in the southeastern states have accentuated the necessity to implement effective water conservation programs. Implementation of stormwater quality and conservation technologies can assist communities to achieve environmental standards while preparing for future potable water shortages.

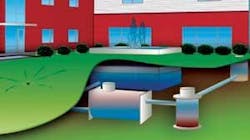

The integrated technologies described herein are designed to capture, treat, harvest and reuse rainwater that would otherwise have been lost. The application of this sustainable approach to stormwater management addresses environmental health, efficient land use, and return on investment when compared to traditional stormwater management plans.

Integrated Technologies

Integrated stormwater management technologies have been implemented for a LEED inspired corporate headquarters building in Chattanooga, TN. Constructed in 2008, the two-story 12,500 square foot office and warehouse building is located on 1.2 acres within a small industrial/office park where conventional public domain stormwater management practices are employed. The technologies implemented at this site serve to reduce pollution from stormwater runoff, limit the disruption to the natural site hydrology by reducing impervious cover, increase infiltration, and allow for the reuse of water to reduce potable water demand and costs.

Figure 1. Process flow for integration of water quality treatment, harvesting and reuse.

The process flow begins with the collection of both stormwater and roof runoff into a junction manhole (see Fig. 1). From there, water is plumbed to an underground manufactured water quality treatment device that utilizes a treatment train approach. The first component of the treatment train employs a hydrodynamic separator (swirl concentrator), while the secondary component uses a filtration chamber. The treatment train is constructed entirely of high-density polyethylene (HDPE) and contains no moving parts. The system is sized to treat a water quality flow rate of one cubic foot per second (448.8 gallons per minute).

The swirl chamber measures three feet in diameter and 5.5 feet in height. The unit is designed for pretreatment by removing coarse-grained sediment, floating debris, and free-floating oil. Operations begin when stormwater enters the swirl concentrator by means of a tangential inlet pipe, which induces a circular (swirl or vortex) flow pattern. A combination of gravitational and hydrodynamic drag forces results in solids dropping out of the flow and migrating to the center of the swirl chamber where velocities are the lowest. The treated flow exits the swirl chamber behind an arched inner baffle. The top of the baffle is sealed across the treatment channel to eliminate floatable pollutants from escaping the system. A vent pipe is extended up the riser to expose the backside of the baffle to atmospheric conditions, preventing a siphon from forming at the bottom of the baffle.

Once pretreated water leaves the swirl chamber, water enters the filtration chamber which is designed to remove oils, fine-grained sediments, and heavy metals (as particulate). Perlite filter media is installed in this system. The filtration chamber measures 10 feet in length and seven feet in diameter. A total of 24 square feet and 24 cubic feet of perlite filter media are inserted in individual containers which are secured and layered in rows patterned to minimize short-circuiting. Water entering the filtration chamber is evenly distributed across the filter bed and allowed to permeate downward under gravity flow conditions through the filter media. Sediment is trapped within the interstitial spaces throughout the porous perlite media.

The perlite filter media used in this filtration chamber also provides for the removal of waterborne pathogens. A proprietary EPA-registered organosilane antimicrobial agent is applied to the perlite filter media, which provides long-term treatment in an environmentally neutral manner. The mode of action for the filter media is an instantaneous process that physically kills gram positive and negative bacteria, viruses, fungi, yeast, molds and spores on contact. The destroyed pathogens then easily pass through the filter media without clogging. The filter material does not rely on physical trapping and leaves no chemical or environmental residue. No external energy source is needed, there are no moving parts, and the filter media is safe to handle. The antimicrobial agent is not consumed and does not dissipate. Effluent water has been determined to be non-toxic through the completion of an acute toxicity testing program following EPA protocols. Since the antimicrobial agent effectively inhibits further growth of microorganisms, the treatment process does not allow for the mutation of microorganisms to occur over time.

Figure 2. Water fountain uses water harvested from stormwater and roof runoff. The fountain sets directly above the underground modular storage unit.

Water harvesting provides for the operation of property and building processes that commonly have relied on the use of potable water. Water conservation is achieved through the use of an underground modular polypropylene storage unit. The harvested water is used for an outdoor fountain, irrigation and toilets (see Fig. 2).

Based on a roof collection surface area of 7,500 ft2 receiving an average annual rainfall of 54 inches, approximately 250,000 gallons of rainwater runoff per year alone would be treated and harvested. The storage tank was sized to store approximately 13,000 gallons of water according to water supply from runoff and anticipated process water usage. The tank design required five individual modules, each having 95% void space, to be vertically stacked to a height of seven feet from the base of the excavation. A total of 85 modules stacked five high were used in 17 adjoining columns. The storage tank occupies an area of 51 ft2 and a volume of 1,820 ft3. The water storage unit is encapsulated with an impermeable geotextile liner. No infiltration from the storage tank occurs. The water fountain feature was constructed directly above the underground storage system and has an estimated operating weight of 30,000 pounds. The load supporting capacity of the modular storage system is not exceeded by the fountain design.

Land Use Benefits

A challenge to site development existed due to the presence of a sanitary sewer line that traverses the property such that it was divided in half with respect to potential building locations (see Fig. 3). A conventional, lower cost approach to stormwater management included the use of an open detention pond. While detention ponds are well documented for their water quality and quantity benefits, their installation occupies land that could be used for other purposes. Figure 3 illustrates a site development plan using a detention pond (left), the office/warehouse (lower right), and a future facility (upper left). If this approach were followed, 11% of the available land use area would have been lost, and plans for the future facility would be reduced by one half the projected size (when using the integrated technologies).

Land use area was increased to 100% by utilizing the underground water storage system instead of the detention pond. Through the use of the integrated technologies, a larger future commercial facility (3,250 ft2) could be constructed and additional parking spaces could be located in place of the detention pond (see Fig. 4). Thus, efficient land use was realized through the use of the integrated stormwater management technologies.

Figure 4. Integrated stormwater management technologies allow 100% land use and larger future facility than allowed by detention pond design scenario.

A unique approach to parking space utilization was achieved through the combination of load-supporting drivable grass and gravel paving technologies. Two parking areas utilize grass and gravel methods while one parking area relies on gravel paving. Vehicles access the property from the street via an asphalt driveway and enter the parking areas on the drivable grass (Figure 5). Parking occurs in gravel strips positioned on each side of the drivable grass.

Both the grass and gravel areas are underlain with load supporting polypropylene cell panels that prevent rutting from traffic, protect turf roots, promote grass growth and enhance infiltration. Harvested water can be used to irrigate the drivable grass. These paving technologies are capable of safely consuming moderate engine oil drippings. All parking areas are ADA compliant.

While the paving technologies enhance the viewscape, they also reduce hot surface temperatures and, in turn, the urban heat island effect caused by traditional paving materials.

Return on Investment

Through effective integration of the water management technologies allowing for 100% land use, an increase in equitable position was achieved leading to an almost immediate return on investment. For example, a larger commercial building space and additional parking space is now available that otherwise would not have been realized with the detention pond development plan. Thus, additional options for future development are now available through the efficient land use planning.

The upfront cost of the underground storage unit exceeded the cost of a detention pond by $17,400. When additional expenditures associated with irrigation and toilet plumbing are considered, the sustainable technology implementation expenses increased to approximately $21,700 over that of the detention pond costs. Using harvested rainwater for property process water, however, is projected to result in a reduction of potable water usage by 51% based on the number of building occupants and usage levels. A reduction in potable water use will lead directly to a reduction in water utility expenditures.

A return on investment is correlated to be less than six months for the underground storage system, and less than seven months for its installation inclusive of irrigation and toilet plumbing. By comparing the increased cost for the conservation technology with the additional revenue (equity) generated from rental income from the future facility, and once the return on investment is reached, the ongoing revenue stream generated leads to an additional increase in equitable position.

Conclusions

The incorporation of the water quality and water quantity technologies into a sustainable integrated use system requires advanced design planning compared to traditional water management practices. The benefits of their implementation can be realized in terms of practical uses and operational costs of water usage. These technologies also enable a greater percentage of land use, increasing the equity position of the owner. Ongoing cost savings will also be realized due to a decrease in potable water use through the implementation of these systems.

About the Author:

Mark B. Miller is a research scientist with AquaShield (Chattanooga, TN).