Reverse Osmosis technology may be gathering momentum but other membrane technologies are being proven with products coming to the market. Dr Graeme Pearce looks at the potential behind Forward Osmosis and Pressure Retarded Osmosis. Could a combination of the two be the answer to brine disposal challenges?

In 2005, 99.5% of water abstracted was from freshwater sources, with the balance coming from seawater desalination or wastewater reuse [1]. Surface water provided the majority of the water resource, but 36% came from groundwater sources. Groundwater is under increasing threat since it is effectively a non-renewable source, taking millennia to accumulate, but just a few years or decades to deplete. Also, groundwater is deteriorating in quality due to human activity, becoming polluted from agricultural residuals, and in some areas by saline intrusion.

The development of new resources is therefore critical. Ultimately, alternative resources will need to displace a significant proportion of groundwater sources. Indeed, it is predicted that reuse levels of 20% or 30% will become common for many developed areas [2] and that water scarce areas may need to provide more than 70% of their water resource from alternative sources. In addition, economic development is normally accompanied by increasing water use, though there are indications that this trend will eventually reverse due to better management of resources and conservation at the point of use.

Two options for alternative water resources are desalination of seawater and wastewater reuse. The former is too energy intensive for widespread adoption, but may be seen as the only choice in dry climates. Wastewater reuse makes more sense in terms of energy use, but has been slow to gain public acceptance.

Direct Osmosis

There is another approach to water resource development with the potential for lower energy use and better public acceptability. This approach is based on the principle of direct osmosis. Depending on how the osmotic principle is applied, osmotic processes also offer the potential for energy generation. Although direct osmosis processes have been around since the 1960's [3], commercialisation is relatively recent.

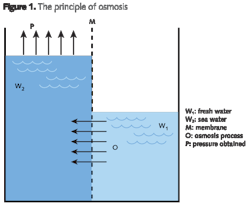

Osmosis is a process in which water is transported through a semi-permeable membrane due to a difference in chemical potential between the solutions. Figure 1 shows freshwater (W1) separated from seawater (W2), by a membrane. Water has a tendency to diffuse through the membrane from the freshwater side to dilute the higher salinity solution, generating a head of pressure which is dependent on the salinity difference of the two solutions.

At first glance, this does not seem to be useful from a water resource standpoint. The process provides a smaller quantity of freshwater and a larger quantity of a less saline saltwater, an inevitable consequence of the second law of thermodynamics. The more normal way to exploit the osmotic principle for water resource development is to operate the process in reverse, ie apply pressure to the saltwater side to initially overcome the osmotic pressure and then drive water from the saline to the freshwater side, ie reverse osmosis (RO). However, the energy cost of RO is considerable.

Direct osmosis processes offer a novel approach to water resource development and the potential for harnessing energy through different system designs by exploiting the osmotic principle. Various embodiments of the concept exist. Systems which are designed to produce water are normally called Forward Osmosis (FO) systems, though the term Manipulated Osmosis Desalination (MOD) is also used by one supplier.

Energy recovery schemes are normally termed Pressure Retarded Osmosis (PRO). A number of variants and combinations of these process schemes are being investigated, together with the combination of FO and PRO with other membrane technologies such as RO and membrane distillation.

Forward Osmosis (FO)

In the FO process, a draw solution is used to create a driving force for freshwater to pass through the membrane. An early commercial application for this idea was in the development of a sweetened drinking beverage for the US army. An impaired freshwater source such as a contaminated pond or brackish supply can provide the low salinity water source while a concentrated sugar solution provides the draw solution.

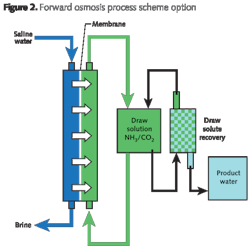

Normal drinking water can also be produced by using a process scheme as illustrated in Figure 2, in which the draw solution can be separated from the freshwater drawn through the membrane [3, 4]. In this example, an ammonium bicarbonate solution is used as the draw. The solution is diluted by freshwater. Applying heat separates the ammonium carbonate into ammonia and carbon dioxide which can be recycled. The energy use of this type of scheme is claimed to use only 20% of the energy of RO desalination schemes [5]. Clearly a low grade waste heat source could improve the economics of energy use further.

FO schemes are not able to use standard commercial RO membranes due to polarisation effects, but instead have reverted to cellulose acetate based membranes, similar to the original RO products [3]. First generation FO products have recently been introduced to the market from several suppliers.

Pressure Retarded Osmosis (PRO)

The concept behind PRO is to focus on using osmotic pressure to generate energy. PRO can provide a combined water production and energy recovery scheme. Wherever freshwater meets the ocean, there is an opportunity to recover the energy released by freshwater mixing with saltwater.

WWi Market Watch: The Forward Osmosis Race- October 2010 saw Chinese company Tri-Tech Holding sign an international distribution, services and cooperation agreement with forward osmosis membranes, modules and systems manufacturer Hydration Technology Innovations (HTI), based in Oregon. As part of the contract, Tri-Tech will sell HTI forward osmosis technology in the People's Republic of China. It was back in August 2010 that HTI launched its brand of OsMem FO membranes.

- Cambridge, Massachusetts-based Oasys Water has started commercialisation of a new, thin-film compostite (TFC) polyamide membrane developed for forward osmosis. The company officially opened a new development facility in Boston at the end of December, 2010. It claims the FO process only uses one tenth of the fuel compared to conventional desalination processes.

- Across the Atlantic UK-headquartered Modern Water, a firm behind Manipulated Osmosis (MO) technology said in June 2010 that it had agreed an extension to a trial of its desalination facility in the Middle East with Omani Public Authority for Electricity and Water (PAEW). A further six-month term was agreed. To date two plants are using the company's MO desalination technology, including Gibraltar and Oman.

The potential for energy recovery is substantial. For example, presenters at a recent meeting estimated that 20% of the power needs of the Netherlands [6] and at least 15% of the requirements of Canada [7] could be met by PRO schemes. Canada, which relies heavily on renewable sources for its electricity supply, is keen to investigate PRO since it has a much lower embedded carbon footprint than hydro-electric power. PRO has a similar carbon footprint to wind power (though it is higher than Solar Photovoltaic). An advantage of PRO over other alternative energy sources is that it would be continuous and virtually independent of weather, season, or time of day. However, technical challenges are significant.

Each 1¢/m3 spent of pre-treating the feed adds 10¢/kWhr to the electricity cost [8]. Pre-treatment costs would be expected to be at least at the 1¢/m3 level and could easily be higher.

Combining Forward Osmosis with Reverse Osmosis

An important recent development is to combine FO with RO [9, 10]. A perfect opportunity for this occurs at the coast where an impaired freshwater stream, such as a wastewater discharge, can provide the feed for the FO unit and seawater can provide the draw solution. The FO process dilutes the seawater, producing a lower salinity feed for the RO stage. The RO concentrates the low salinity feed back up to the natural seawater concentration. The seawater reject can either be discharged back to the sea or partially recycled.

This scheme avoids the problem of concentrate disposal, which creates a permitting problem for many desalination schemes. It also helps avoid the negative public perception issue surrounding wastewater reuse, since the wastewater feed has to be pre-treated prior to the FO stage, probably by a UF pre-treatment, and then passes through a double FO/RO membrane barrier.

Conclusions

Direct osmosis schemes offer enormous potential as an alternative water resource with a low energy requirement. Also, these schemes could be used for power generation. Combined with existing membrane technologies such as RO, Forward Osmosis could provide freshwater from wastewater with less public resistance and a much reduced environmental impact. Products are now just being introduced to the market, though the commercial status of the technology is still in its infancy.

References

[1] Global Water Intelligence Wastewater Reuse Report, 2005

[2] Reuse or Run Out, S Milmo, The Chemical Engineer, 20-22, April 2009

[3] A Novel Ammonia Carbon Dioxide Forward Osmosis Desalination Process J. R. McCutcheon, R L McGinnis, M Elimelech, Desalination 174 (2005) 1-11

[4] Energy Issues in Desalination R Semiat, D Hassan, 1st UK-Israeli Workshop & Research Event, Oxford June 2008

[5] Add salt as required: the recipe for fresh water K Ravilious, New Scientist, 207 (2773) 14 Aug, pages 39-41

[6] Performance Evaluation of Pressure Retarded Osmosis S van der Zwan, Proceedings of the 2nd FO Summit at AMTA, San Diego, July 2010

[7] The Development of Alternative and Renewable Sources of Energy and the Role of Osmotic Power in this Context C B Laflamme, Proceedings of the 2nd FO Summit at AMTA, San Diego, July 2010

[8] Introduction to Osmosis Summit S E Skilhagen, Proceedings of the 2nd FO Summit at AMTA, San Diego, July 2010

[9] Combining Forward Osmosis with Reverse Osmosis J Jangbarwala, Desalination & Wastewater Reuse vol 19/1 (2009), 34-36

[10] Reality vs Perception: An HTI perspective K Lampi, Proceedings of the 2nd FO Summit at AMTA, San Diego, July 2010

Author's note: Dr Graeme Pearce is a membrane technologist with 25 years experience in the membrane industry. He is principal at Membrane Consultancy Associates - a consultancy providing advice and guidance in membrane technology for liquid separators, founded in Sept 2005. For more information please email: [email protected].

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles