Managing High Wet Weather Flows with MBRs and High-Rate Clarification

To counter wet weather flow or significant amounts of infiltration/inflow (I/I) an MBR system can be coupled with a biological contactor followed by the high-rate microsand ballasted clarification process. Both processes have a compact footprint and can be on-line and producing treated effluent within 20 to 30 minutes. The combination of these technologies allows for a cost-effective solution for wastewater treatment plants that require the high quality effluent that MBR provides, but experience high wet weather flows.

By Hong Zhao and Chinh Hoang

Around the world, membrane bioreactors (MBR) are attracting increased attention in terms of commercial applications and technology research. Once a wastewater treatment technology that was not considered for applications above 5 million gallons per day (mgd), MBRs are now being installed for capacities in excess of 40 mgd.

MBRs combine, in one stage, biological treatment with membrane separation that, in concept, is essentially an activated sludge plant with the final clarification stage replaced by a membrane filtration system. The rapid growth of MBR use can be attributed to advantages such as compact footprint, minimum operator attention required, and a tertiary effluent ready for re-use. Plus, the membrane eliminates the need to rely on the settleability characteristics of the sludge.

The activated sludge process for the MBR system can be configured in a multitude of ways depending on the effluent requirements of the plant. Configurations will depend on whether the plant needs to achieve biological oxygen demand (BOD) removal and nitrification, nitrification/denitrification, phosphorus removal, or denitrification and phosphorus removal.

In addition to the design flexibility and performance advantages of MBRs, the rapid growth in the use of this technology at higher flows has also resulted from recent reductions in membrane costs and steady increases in commodity costs such as steel and concrete. Also, MBRs require smaller tank volumes, allowing for the technology to be applied to larger applications more economically than in the past.

MBR’s Former Nemesis: High Weather Flows

MBRs tend to lose their economical advantage when a wastewater treatment plant has high wet weather flows or significant amounts of infiltration/inflow (I/I). The membrane provides an absolute barrier, which can be both a blessing and a curse during wet weather flows.

The absolute barrier allows for the combined activated sludge (CAS) process to operate at mixed-liquor suspended solids concentrations 3 to 4 times higher because the settleability characteristics of the activated sludge are no longer a concern. The high mixed-liquor concentration also allows for the footprint of the biological plant to be a third to a fourth that of a conventional plant. However, the absolute barrier also limits the flow volume that can pass through the membranes.

This is unlike a conventional plant, which uses a clarifier to handle the liquid/solid separation. A clarifier will allow effluent to pass through during high peak flows, although the resulting effluent quality diminishes because solids are washed out.

In order to handle high wet weather flows, MBRs had traditionally required either additional installed membrane areas (to provide additional capacity) or a large equalization volume, or a combination of both. Large equalization tanks take away from the small footprint advantages of the MBR. Increasing the membrane capacity boosts capital costs due to the cost for the additional installed membrane area. Also, larger tanks are required to house the additional membrane modules. Operating costs also increase because there is more membrane area that requires air scouring, scheduled chemical cleanings, and replacement at the end of its design life.

Combining Technologies to Solve the Problem

Innovative technologies have recently provided a solution to this dilemma. To counter wet weather flow or significant I/I, the MBR system can be coupled with a sidestream biological contact process followed by the high-rate microsand-ballasted clarification process, ACTIFLO® (see Fig. 1.) The combined biological contact and high-rate clarification treatment has a compact footprint and can be on-line and producing secondary effluent in 20 to 30 minutes. This provides for a cost-effective solution for treatment plants requiring the high-quality effluent MBR provides but that also experience high wet weather flows or high I/I.

Sidestream Processing

The sidestream process of a biological contact followed by ACTIFLO clarification is called BioACTIFLO®. As the flow increases beyond the MBR system’s designed capacity, the additional flows are diverted, after screening, to the sidestream biological contact chamber. The chamber uses mixed liquor suspended solids (MLSS) from the existing activated sludge system along with the introduction of diffused air to absorb soluble BOD as these contents contact with MLSS. The oxygen requirement in the contact tank is 0.04 lbs O2/lb total suspended solids (TSS), versus the 1.42 lbs O2/lb TSS that would be required in a suspended solids growth activated sludge treatment process. In addition, influent particulate BOD is incorporated into flocs inside the sidestream contact chamber.

Once the soluble BOD is absorbed by the MLSS in the reaction chamber, the flows pass into the ACTIFLO System where the MLSS are coagulated, flocculated, and settled out, resulting in total BOD removals greater than 75%. Microsand, used as a ballast site for the solids to adhere to, is sent to a hydrocyclone that separates the solids from the sand. The solids are returned to the MBR and the microsand is returned to the flocculation tank.

Following BioACTIFLO treatment, the effluent is then combined with the MBR effluent, resulting in a total influent flow that has achieved secondary treatment prior to discharge. Typical hydraulic retention time for the sidestream treatment system is approximately 45 minutes.

Successful Trials

Much testing has been performed with the BioACTIFLO process to determine proper hydraulic retention time (HRT) for the contact tank; proper MLSS level in contact tank; the required oxygen supply and rise rate for the ACTIFLO.

During testing on a unit in Fort Smith, AR, for example, several combinations of MLSS and contact times were evaluated for soluble BOD absorption, including 250, 400, 600, 800, 1,000, and 1,200 mg/L. MLSS concentrations were calculated based on flow rates / TSS concentrations of primary effluent and return activated sludge (RAS).

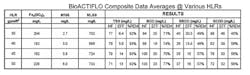

Due to variations in primary effluent and RAS concentrations, grab samples were taken throughout the Fort Smith pilot study to verify the actual MLSS concentration for each extended run. The blend basin was operated at three different volumes to yield a high, middle, and low retention time. In addition, ACTIFLO was operated at 30, 40, 45, and 50 gpm/ft2, and contact times were calculated using equalization basin volume and ACTIFLO’s rise rate. Table 1 summarizes the results of BOD removal at the various contact tank mixed-liquor concentrations.

Full-scale testing of BioACTIFLO was also performed at the Milwaukee Metropolitan Sewage District. The trial demonstrated that the system delivers a treated effluent of similar quality to that of a secondary treatment process while satisfying the requirement of providing a cost-effective, technology-viable method for gaining very large additional biological processing capabilities that would typically be utilized only a few times during the year during high wet water flows.

Handling Peak Flows Above 2x

Combining MBRs with BioACTIFLO provides a unique solution for the treatment of wet weather flow and high I/I. Handling peak flows above 2x (two times design flow) has always been a difficult and costly proposition for membrane bioreactors. Combining the two treatment technologies provides a compact and cost effective way to handle wet weather flows above and beyond 2x.

WW

About the Authors: Hong Zhao is Process & Technology Leader – Wastewater for I. Kruger Inc., a Veolia Water Solutions & Technologies company. He can be reached via email at [email protected]. Chinh Hoang is MBR Group Process Manager for I. Kruger Inc., a Veolia Water Solutions & Technologies company. He can be reached via email at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles