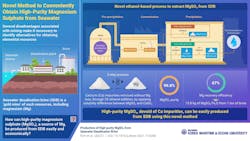

New method to extract magnesium sulfate from desalination

A group of Korean researchers, led by Professor Myoung-Jin Kim, from Korea Maritime and Ocean University, have succeeded in extracting 99.8 percent pure magnesium sulfate (MgSO4) from just seawater desalination brine.

Speaking about the motivation behind the study, Prof. Kim exclaims, “Since we have already developed a sophisticated seawater desalination process to address the world’s water needs, why not couple it with the beneficial process of mineral extraction! In this way, we believe that such extraction can be performed in an energy-efficient, sustainable, and environment-friendly manner.” The team’s findings have been published online, in Volume 518 of the journal Desalination.

The team has not only coupled the two processes of desalination and mineral extraction, but has also developed a novel and subtle ethanol-based process to extract the MgSO4. Initially, the researchers followed steps such as alkali-based magnesium hydroxide pre-precipitation from brine, and sulfuric acid-based magnesium concentration. Finally, they treated the magnesium eluate, twice, with ethanol—the first time to remove calcium impurities, and the second time to precipitate the high-purity MgSO4.This final two-step process used the difference in solubility between magnesium and calcium sulfates in ethanol, to achieve up to 67 percent magnesium recovery efficiency.

Owing to the cost-effectiveness of mineral extraction from desalination brine, the researchers hope that the obtained MgSO4 may not only be used for re-mineralizing desalinated fresh water, but also find potential applications in the pharmaceutical and food industry. Prof. Kim adds, “We hope that our study encourages further research on alternative mineral extraction processes.”