Resource Recovery in Wastewater Treatment

By Thacher Worthen

In light of the increase in water and energy demands and their associated cost, public attitude toward wastewater is changing from "out-of-sight, out-of-mind" to being viewed as a valuable resource. From this resource, water can be reused to minimize impacts of exploiting new sources of supply. Nutrients, such as phosphorus, can be recovered in various forms for use in agricultural fertilizers. Energy, in the form of heat and electricity, can be extracted from organics to offset power demands of the facility.

That said, there are many barriers that need to be overcome in order for these positive outcomes to be realized as beneficial by public utilities. One of the prominent barriers is advancing innovative technologies that can be used reliably and economically for resource recovery. Traditionally, wastewater treatment plants have been publicly owned entities, and the adoption of new technologies has been viewed with skepticism because of a fear of failure resulting in a loss of trust by ratepayers.

To overcome the slow adoption of new treatment technologies for resource recovery, utilities need to collaborate with equipment manufacturers, consultants and academia in evaluating, testing and implementing technologies. All parties benefit when technologies are assessed in a transparent and thorough manner. Scientifically defensible assessment of technology readiness and viability can help secure capital investment, minimize risk of failure and achieve successful implementation. In addition, it provides a framework for regulatory agencies to endorse the innovations as part of the permitting process.

This is the same approach taken by the Leaders Innovation Forum for Technology (LIFT) initiative, which was launched jointly by WEF and the Water Environment Research Foundation (WERF). LIFT recently started a program called Intensification of Resource Recovery, or IR2. The program is designed to accelerate innovation in the water sector and to move new technologies more rapidly into practice. IR2 treatment technologies are defined as those that can help municipalities reduce their capital cost by more than 30 percent (e.g., smaller footprint). In addition, these technologies can reduce operations and maintenance costs through resource recovery including water reuse, nutrient recovery and enhanced energy recovery.

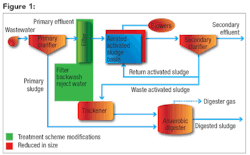

A key example is primary effluent filtration (PEF) for carbon diversion. In this emerging technology, the carbon-rich solids are captured in the filter backwash reject water and then diverted to the anaerobic digester after thickening.

To demonstrate that PEF technology is commercially attractive for carbon diversion, a 2-year demonstration project, funded by a grant from the California Energy Commission, was conducted at the Linda County Wastewater Treatment Plant in Marysville, Calif. Five different types of filters were evaluated for filtration of primary clarifier effluent; however, only two were successfully operated continuously for 24 months: the cloth depth filter and the compressible medium filter.

One of the key features of the PEF technology is energy cost savings as a result of the decrease in required aeration energy in secondary treatment, and the increase in gas energy production in the anaerobic digester due to the high energy content of the captured organic solids in filter backwash water. According to Dr. Onder Caliskaner, the principal investigator of the demonstration project, "Assuming 25% implementation of the emerging technology in California, it is estimated that the annual energy cost savings would be approximately $29 million per year."

The formation of partnerships between utility owners, their consulting engineers and technology providers (i.e., equipment manufacturers) through implementation of full-scale installation will help share the cost and risk of moving PEF technology into practice.

About the Author: Thacher Worthen is President of Schreiber Corporation Inc., Trussville, Alabama, and is a member of the Board of Directors of the Water and Wastewater Equipment Manufacturers Association.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles