WAO treats spent caustic liquor in Asia and Brazil

By Claude Ellis, Clayton B. Maugans, Ph.D.

Spent caustic liquors from ethylene production and oil refining are "real stinkers" in the world of industrial wastewater.

In ethylene production, spent caustic liquors typically come from the scrubbing of cracked gas with aqueous sodium hydroxide. In oil refining, the liquors emanate from caustic washing, which is practiced to improve the quality of the product and to aid in the refining process.

Photo by USFilter Zimpro Systems

Conventional biological processes cannot effectively treat these odorous liquors, high in chemical oxygen demand (COD) and contaminants, such as sodium sulphides, mercaptans, phenols, and emulsified hydrocarbons. In many cases, they must be hauled away to costly off-site treatment and disposal.

Wet air oxidation (WAO), a process developed by USFilter Zimpro Systems in Rothschild, Wisconsin, USA, is being used more and more to treat and neutralise these streams on-site. WAO wipes out the odours, destroys contaminants, significantly reduces COD levels, and produces a benign effluent that can be treated in a plant's conventional biological wastewater treatment facilities.

WAO is an aqueous phase process using oxygen contained in air (or any other oxygen-containing gas) as an oxidant. The process operates at elevated temperatures and pressures ranging from 120°C to 320°C and 760 kPa to 21000 kPa, respectively.

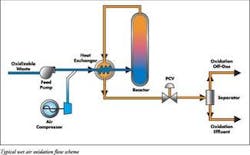

In the basic WAO flow scheme (see diagram), wastewater or feed liquor is pumped up to pressure by a high pressure feed pump. A gas stream containing sufficient oxygen to meet the oxygen demand requirements of the waste stream, in this case air, is injected into the pressurised waste stream, and the air/liquid mixture is preheated to the required reactor inlet temperature.

The mixture is held in the reactor for sufficient time to allow the oxidation to approach the design reduction in COD. Oxidation reactions, being exothermic, produce a temperature rise in the reactor, making the reactor outlet temperature higher than the inlet temperature. This temperature differential allows for the recovery of heat from the hot reactor effluent by preheating the feed to the reactor.

In most cases, more thermal energy is available than required for preheating the reactor feed. After heating the reactor feed, the reactor effluent usually requires further cooling before discharge. The final step is to reduce the pressure of the reactor effluent stream and separate the vapour and liquid, which is typically discharged to a biological treatment plant for final polishing.

Temperature is the most critical variable to be considered in WAO system design. A higher degree of oxidation can be achieved as the temperature is increased.

WAO of sulphide spent caustic is practiced generally at the lower end of the temperature scale. Conventional ethylene spent caustic is usually oxidised at temperatures between 130°C and 220°C. Higher temperature systems, operating from 240°C to 260°C, are usually applied to the naphthalenic and cresylic spent caustic found in refineries.

Ethylene spent caustic

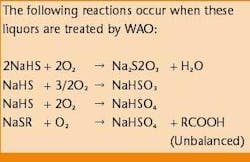

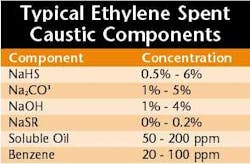

Spent caustic derived from scrubbing ethylene gas typically contains a range of various components, shown in the table below. The exact composition of the spent caustic liquor will depend on the contaminants in the ethylene gas being scrubbed, which of course is dependent upon a number of factors including feed stock and furnace operating conditions.

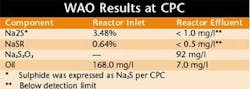

At the Chinese Petroleum Corporation (CPC) in Kaohsiung, Taiwan, three WAO trains treat spent caustic from CPC's number 2 and number 5 naphtha crackers. The system operates at a temperature of 200°C and a pressure of 2760 kPa. Each system has the capacity to treat 5.67 m3/hr of spent caustic.

The system went on-line in late November 1990, and has been in continuous operation ever since. The elimination of sulphide odours associated with the ethylene spent caustic is critical to the plant's continuing operation. Since start-up, the sulphide content of the oxidised liquor has always been below 1 mg/l. In addition, the system oxidises more than 90% of the spent caustic's soluble oil content, producing an effluent that is clear as water. The treated liquor is pumped to conventional biotreatment.

Refinery Spent Caustic

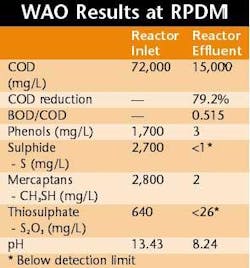

In 1995, a WAO system was put into operation to pre-treat refinery spent caustic for discharge to the existing biological treatment facilities at the Refinaria de Petroleos de Manguinhos, S.A. (RPDM) in Rio de Janeiro, Brazil. The liquors emanate from gasoline sweetening, gasoline and LPG prewashing and from gasoline and LPG mercaptans extraction.

While the WAO process is similar to ethylene spent caustic applications, higher temperatures are required to meet treatment objectives for refinery spent caustics containing cresylic and naphthenic compounds, and control foaming in the reactor.

Provided by USFilter Zimpro Systems

Prior to the installation of the WAO unit, the spent caustic was stored on-site and periodically trucked to a nearby Petrobras refinery for disposal by incineration. However, rising waste disposal costs, odours from the stored spent caustic, and the development of housing near the refinery were grow-ing concerns. The refinery selected on-site treatment of the spent caustic to eliminate these issues.

Performance and overall reliability since start-up has been good. Approxi-mately 80% destruction of COD is achieved, with near complete phenols (cresylic) destruction and sulphide levels reduced to below detection limits, at temperatures of around 250°C.

The unit was run continuously for the first years of operation in order to treat production as well as stockpiled spent caustic. Now the unit is operated every other week to treat production spent caustic as it accumulates. No dedicated operators are assigned to the WAO unit. Operation is performed as necessary by RPDM refinery staff.

Conclusion

These successful applications demonstrate that refineries and ethylene producers continue to look to wet air oxidation as a solution for spent caustic liquors. Currently, USFilter Zimpro Systems is supplying WAO systems to Fujian Petrochemical and Shanghai SECCO Petrochemical Co.

Overall, since introducing WAO to the wastewater treatment market in the early 1960s, USFilter Zimpro Systems has designed, manufactured and installed more than 150 systems for such wide-ranging applications as sludge conditioning and disposal, black liquor recovery, toxic waste destruction, and industrial resource recovery and pollution control.

Authors' Note

Claude Ellis, the director of marketing for wet air oxidation products at USFilter Zimpro Systems in Rothschild, Wisconsin, USA, has worked on WAO technology at USFilter for 31 years. Clayton (Clay) B. Maugans, Ph.D. is a hydrothermal research specialist at USFilter Zimpro Systems, who specialises in wet air oxidation. Visit the website www.zimpro.com/wetox for more information.

Fujian Petrochemical, a petrochemical refinery in the Fujian Province of the People's Republic of China, is a joint venture between the provincial government and Sinopec. As part of an environmental upgrade to the facility, USFilter Zimpro Systems is supplying an on-site WAO system. The system is designed to treat refinery spent caustic and produce an effluent that can be treated by conventional biological processes.

USFilter Zimpro Systems is supplying a WAO unit for ethylene spent caustic treatment at the Shanghai SECCO Petrochemical Company's industrial wastewater treatment plant in Caojing, People's Republic of China. The technology will help SECCO alleviate two problems frequently associated with ethylene spent caustic: disposal and odour. ABB Lummus Global and Sinopec Engineering are providing engineering and procurement services for the new complex.