Selecting the Right Mechanical Seal Housing can Increase Seal Life

By Allan R. Budris

As pointed out in the July 2011 Pump Tips Column, on Mechanical Seals, the housing design around the mechanical seal can have a large impact on the life of the mechanical seal and the types of mechanical seals that can be installed in a pump.

When mechanical seals were first developed, most pump shafts were sealed with packing, so the mechanical seal designs were required to fit into a packing stuffing box. However, over the years, pump users and manufacturers came to realize that the tight confines of a stuffing box did not allow enough liquid circulation around the mechanical seal to remove sufficient heat and/or to keep solids in the pumped liquid away from the seal faces, to achieve desired seal life. This has lead to the development of various dedicated “mechanical seal housings” that provide more space around the mechanical seal, which can promote circulation to expel solids and air/vapors from around the mechanical seal faces, and/or reduce seal face temperatures, thus increasing seal life.

The mechanical seal housing types available today are:

- Standard Stuffing Box

- Cylindrical Large Bore Seal Chamber

- Enlarged Tapered Bore Seal Chamber

- Enlarged Tapered Bore w/ Stop Rib Seal Chamber

- Enlarged Bore / Special Particle Removing Throat Bushing

- Enlarged Tapered Bore, Cyclone Seal Chamber

Each of these mechanical seal housings has its advantages and limitations, depending on the liquid / solids/ vapors handled.

Standard Stuffing Box:

The advantages of a standard stuffing box is that it is probably the lowest cost design, plus the mechanical seal can be replaced by packing rings in an emergency. However, for good mechanical seal life, this type of housing should be limited to clean, ambient water, with a stuffing box flush off of the pump discharge.

Cylindrical Large Bore Seal Chamber:

The advantages of a Big Bore Cylindrical Seal Chamber is that it provides more space for the seal, for solids to be centrifuged away from the seal faces, and for a greater liquid volume that will remove friction heat away from the seal faces. As a result, this seal chamber provides a measurable extension of the mechanical seal life, and can fit all standard o-ring mounted seals (single or double). Some of these housing designs even have an internal bypass to flush solids from the seal chamber.

Cylindrical large bore seal chambers should not, however, be used when solids are present in the pumped liquid, without a seal flush, for high boiling point liquids, or for applications requiring self-venting and draining.

Enlarged Taper Bore Seal Chamber:

Large Bore seal chambers are also offered in “Taper” construction (see figure 1), to increase cooling liquid circulation to the seal. This construction can, however, cause problems when handling solids, due to abrasive wear that can penetrate the bottom of the box, unless it is modified for abrasive handling, such as by adding axial ribs. The advantage of a pure enlarged taper bore seal chamber, over a cylindrical enlarged bore, is some improvement in self-venting and draining. However, this comes with inferior solids handling, even with a seal flush.

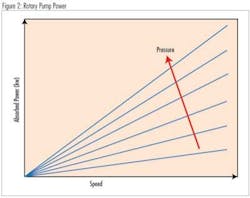

Enlarged Tapered Bore w/ Stop Rib Seal Chamber

Fortunately, simple axial “stop” ribs (see figure 2) have been found to prevent the abrasive wear problem with the pure enlarged tapered bore seal chamber, by generating an axial flow in and out of the seal chamber. This improves both solids and vapor handling. Up to 10% solids can be handled with an external clean flush. Liquids close to their boiling point can be handled with no flush, because these housings have improved self-venting and draining.

Enlarged Bore/with Special Particle Removing Throat Bushing

Special throat bushings containing a ring of vanes or spiral tracks have been found to further improve the removal of both solids and vapors from the seal chamber, even without a liquid flush. Large amounts of money are spent on pump flushing water and seal maintenance, an often surprisingly high expense for wastewater operation management.

The writer is aware of two such seal housing devices, each offering a sealing arrangement that requires little or no flush water, which can save substantially on maintenance and seal flush water costs. ITT Goulds offers a “Vane Particle Ejector Ring” (see figure 3) for their ANSI B73 Chemical pump line (Model 3196), which can also be used for general water service applications, as discussed in the writer’s August 2011 Pump Tips column. This zero flush technology feature is also available from EnviroSeals, in the form of their patented SpiralTrac throat-bushings. The Patterson Pump Co. uses this SpiralTrac device on their Type “F” sewage and Forceline NCS non-clogging series pumps.

These stationary devices are pressed into the pump backplate, just behind the impeller, and essentially replace the throat bushing. They take advantage of the natural circulation of process fluid inside a stuffing box, since the fluid in the stuffing box spins with shaft rotation. Fluid acceleration and the accompanying centrifuge effect separate solids for expulsion with the exiting flow. This high operating flow also assists in removing heat from the seal faces. By modifying the flows that exist inside rotating processing equipment, these two devices allow particulate to be removed from the stuffing box and away from the mechanical seals, it permits air to evacuate the stuffing box on flooding, and minimizes heat buildup in the stuffing box by creating circulation around the seal faces.

Entrained air can collect in a stuffing box or seal housing, either from start-up as the pump is flooded or over time from the liquid being pumped. This air will surround the mechanical seal during equipment operation as the heavier liquid centrifuges to the mechanical seal housing wall, resulting in higher seal heat and wear. These devices release this potentially damaging entrained air out of the stuffing box / mechanical seal housing.

Even though these inexpensive add-ons can eliminate, or as a minimum reduce, the flush quantities required to prevent particulate from overwhelming the seal, there are applications involving fluids at or near the vapor point where flashing concerns mandate caution. Also, different applications may require somewhat different versions or contours, and these are stocked by EnviroSeals and its distributors. By being able to operate successfully with no flush water, the operator can save on the initial installation cost, in addition to long-term costs associated with having to flush the stuffing box. Ultimately these devices increase seal life by leaving a cleaner fluid in the stuffing box for the mechanical seal.

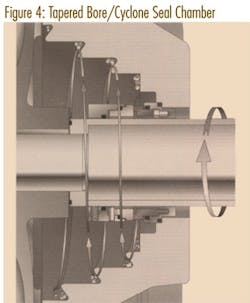

Enlarged Tapered Bore, Cyclone Seal Chamber:

Another very effective seal chamber design is the Enlarged Tapered Bore, Cyclone Seal Chamber (see figure 4). It was originally developed by ITT Flygt for their submersible sewage pump lines. Subsequently the writer also included this seal chamber design in an ITT Goulds ISO Chemical pump line. This taper bore construction uses an internal housing spiral groove to pump abrasives out of the seal chamber. The writer personally tested this device in the laboratory, where it demonstrated a great ability to remove solids from the seal chamber, away from the seal. It operates in much the same manner as the SpiralTrac throat bushing, but with the spiral track being on the inner surface of the entire seal housing, not just in a throat bushing.

Conclusion

As can be seen above, mechanical seal housing designs have come a long way since the early days, with many devices to choose from. The optimum seal housing design selection should be based on the specific requirements of the service conditions. Selecting the best seal housing, and/or seal flush for the application can have a very large impact on the life of the mechanical seal and the total life cycle cost of the pump installation.

WW

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles