WWTP Chooses Upflow Sludge Blanket Filtration System

Strathmore, Alberta, has experienced rapid population growth in recent years. Due to its proximity to Calgary, the town offers a rural lifestyle, affordable housing and modern conveniences all within a short drive of a major urban center. The increased population was placing infrastructure demands that exceeded existing capabilities. Alberta Environment found it necessary to issue several development moratoriums subsequently restricting local economic growth.

The severe demands being placed on the eight extended-aeration lagoons located on the outskirts of town forced the town to investigate new wastewater treatment options. In order to satisfy the long-term needs of the residents and facilitate growth and economic development, a solution had to be found and implemented quickly. Technology selection criteria required a process that was not only cost-effective for a small community but also environmentally friendly as the treated effluent was to be discharged to a local waterway.

During the final selection process, the consulting engineers evaluated Ecofluid Systems' patented and proprietary USBF (Upflow Sludge Blanket Filtration) process and the widely used SBR (Sequencing Batch Reactor). Both processes are modifications of the activated sludge process and are compact systems compared to conventional activated sludge or oxidation ditch forms of treatment.

The Ecofluid USBF process is the result of over 40 years of research and development, testing and practical experience. The operation of a USBF plant is simple and self-regulating. Wastewater enters the anoxic compartment of the bioreactor where it mixes with activated sludge recycled from the bottom of the clarifier. Agitated and moved in a plug flow manner, the mixed liquor eventually underflows into the bioreactor's aerobic compartment. After aeration, a stream of the mixed liquor enters the bottom of the clarifier where sludge flocs and water are separated by upflow sludge blanket filtration. After separation, clear water overflows into a collection trough and is discharged from the system. To complete the internal circulation loop, activated sludge collecting at the bottom of the clarifier is recycled back into the bioreactor's anoxic compartment.

The USBF technology was ultimately selected as the best solution partly based on the summary analysis of the USBF and SBR processes listed below*. The plant is designed to produce effluent with concentrations no greater than 15 mg/l BOD5 and TSS plus 1 mg/l Total Phosphorus. Due to the modular design of the USBF system, the plant can be readily expanded to meet future growth in a cost-effective manner.

USBF and SBR processes have been proven in the U. S. and throughout Europe to reliably meet all current standards for BOD removal, nitrification and denitrification standards down to an effluent BOD5 level of <5.0 mg/l, TSS of 5-10 mg/l, NH4-N of 1.0 mg/l and a total nitrogen of less than 1.5 mg/l.

The installed power requirements for the USBF process are 30 to 50 percent less than for the SBR process since the SBR process must provide the same amount of oxygen in a shorter period of time, i.e. during the aerated fill cycle and the aerated react cycle.

The USBF process has fewer mechanical components than SBR and therefore is a much simpler process. The only mechanical equipment required is a blower for aeration and the return sludge air-lift pump (in larger plants, a low horsepower axial pump is used for sludge return). Additionally, air-lift pumps rarely fail compared to mechanical pumping systems.

The USBF process with anoxic zone treatment of mixed liquor produces an inherently more stable mixed liquor, lower operating SVI's and a slightly higher removal efficiency for TSS.

The USBF system is more flexible in retrofitting existing plants than the SBR because of the unique single tank upflow clarifier concept and design of the USBF.

The USBF has a 20 to 40 percent smaller land area requirement ("footprint") than the SBR. Both systems are much more compact than conventional activated sludge.

The total electrical and mechanical requirements are much less (20-40 percent) for the USBF than for the SBR form of treatment.

Based on total process requirements including tanks (equal), mechanical support equipment, power requirements, electrical, controls, site work and land area required, it would appear that the USBF system would have a significant cost advantage over conventional activated sludge, the oxidation ditch form of activated sludge and SBRs.

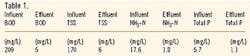

The Strathmore plant was started up July 23, 2001, and the average results of analysis of composite samples for the first week of operation are listed see Table 1. The phosphorus reduction is achieved by biological uptake and alum dosing has not been used.

(*The original texts of the Process Description and SBR Comparison were prepared by John M. Smith of J.M. Smith & Associates of Cincinnati, OH. Mr. Smith has 17 years experience in wastewater treatment research and process design for the USEPA office of Research and Development plus 18 years as an independent consultant.) WW/