The Challenge of Remediating PFAS in Groundwater

About the author:

Ryan Moore, CHMM, is PFAS program manager for REGENESIS. Moore can be reached at [email protected] or 219.286.4838.

By now, you may have heard of PFAS (per- and polyfluoroalkyl substances), a group of chemical compounds numbering in the thousands, detected nearly everywhere anyone has bothered to look, including much of the U.S.’s drinking water. PFAS contaminants found their way into most Americans blood streams largely through drinking PFAS-contaminated water. Exposure to PFAS has been linked to a myriad of severe health problems, including cancer. With growing awareness, many have perceived the regulatory response to PFAS as too slow in relation to the magnitude and effects of PFAS on the U.S. population.

With the change in administration, the U.S. EPA is now directing more of its attention to PFAS. Under the direction of Michael Regan, a veteran PFAS regulatory enforcer (reference), EPA issued its Comprehensive National Strategy to Confront PFAS Pollution on October 18, 2021, with three guiding strategies:

- Increase investments in research;

- Leverage authorities to act now to restrict PFAS from being released into the environment and;

- Accelerate the cleanup of PFAS contamination.

While the first two strategies are relatively straightforward, the cleanup of PFAS contamination is not an easy matter.

RELATED: Talking Under Water Episode 44: How is PFAS a One Water Issue?

Identifying PFAS Sources

“The best way to keep drinking water safe is to protect it at its source.” ~American Water Works Association, 2019 State of the Industry Report (1).

More than 40% of U.S. drinking water is sourced from groundwater. The rest is derived from surface water, which can become contaminated by mixing with PFAS-contaminated groundwater. Therefore, identifying the sources of PFAS-impacted groundwater and remediating these sources is critical to maintaining safe drinking water.

The earliest regulatory attention has focused on PFAS point sources at Department of Defense (DOD) facilities and airports where aqueous film-forming foams (AFFF) were used for routine fire suppression testing and training activities. Overall, however, the PFAS source identification process has only just begun. In June 2021, EPA proposed a rule to require all manufacturers (including importers) of PFAS in any year since 2011 to report PFAS manufacturing, usage and disposal. Once finalized (the statutory deadline is January 1, 2023), the rule will be the first targeted effort under the Toxic Substances Control Act (TSCA) to inventory PFAS manufactured in the U.S., providing EPA with a roadmap of potential PFAS sources. The primary industries that have used PFAS in their manufacturing processes include: pulp and paper mills, textile plants, paint and industrial coating facilities, plastics and specialty chemical producers.

The Nature of PFAS & Cleanup Challenges

Due to their chemistry, there are currently limited options for remediating PFAS in groundwater at the field scale. Born out of the “Better Living through Chemistry” movement dating back to World War II, PFAS were formulated using the strongest bond in organic chemistry — the carbon-fluorine bond — making them essentially indestructible, except under extreme conditions. Unlike other organic groundwater contaminants, such as petroleum hydrocarbons or chlorinated solvents, they are not known to be biologically degradable.

PFAS are polar molecules of carbon-fluorine bond chains with hydrophobic and hydrophilic ends. Their structure gives them surfactant-like properties and makes them excellent, oil, water and stain-repellants. Additionally, PFAS, and especially the longer-chain PFAS molecules (i.e., containing eight or more carbons), tend to stick around (i.e., bioaccumulate) once they enter an animal or human body.

PFAS’s non-degrading, bioaccumulating nature has led to establishing some of the lowest cleanup levels of any groundwater contaminants — less than 10 parts per trillion in some cases — equivalent to one-half-drop in an Olympic pool. Commercial environmental laboratories have only recently evolved their equipment and methods to detect PFAS at these concentrations. Moreover, in the 40-year history of groundwater remediation, most technologies and approaches have not demonstrated the ability to achieve cleanup levels hundreds of times higher (e.g., less than 5 parts per billion) for other contaminants much more easily addressed (e.g., benzene or trichloroethene). For these reasons, PFAS represent perhaps the most significant challenge ever to confront the groundwater remediation industry.

The Interstate Technical and Regulatory Council (ITRC) defines remediation as “a process used to reduce or eliminate the risk for humans and the environment that may result from exposure to harmful chemicals (2).”

Therefore, removing the risk of a potential receptor’s PFAS exposure is the goal of all PFAS remediation. The most common treatment approach for achieving PFAS risk removal is groundwater extraction and filtration. This approach involves interceptor wells that pump groundwater to the surface and filter out the PFAS using granular activated carbon or ion-exchange resins. Pump-and-treat (P&T) has been used for controlling contaminant migration for decades. However, P&T for PFAS remediation is problematic since the treatment can generate many tons of PFAS-contaminated spent carbon and other filtration media. With EPA’s pending hazardous designation for certain PFAS, these spent materials will require them to be managed and disposed of as hazardous waste. This will involve either landfilling or incineration at facilities permitted to handle hazardous wastes.

Landfill disposal of PFAS waste may be viewed as transplanting the problem elsewhere, with potential re-release back into the environment, dependent on how strictly the facility controls leachate. Further, the incineration of PFAS waste has not proved to be effective or safe. According to EPA, “The effectiveness of incineration to destroy PFAS compounds and the tendency for the formation of fluorinated or mixed halogenated organic byproducts is not well understood (3).” In a New York case, incineration of PFAS-containing foams is suspected of having caused soil and water contamination downwind of the facility, leading to a lawsuit against the Department of Defense for allowing the practice (4).

In Situ Treatment of PFAS in Groundwater

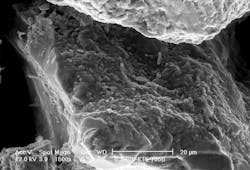

A more recently developed treatment method for removing PFAS from groundwater involves in situ (i.e., in-place) filtration using colloidal activated carbon (CAC). This patented in-ground filtration method works by depositing a permanent carbon coating onto aquifer materials (sands). The result is an immense surface area of activated carbon surface area, transforming the CAC-treated area into a highly efficient in-ground filter. Upon contact, organic contaminants, such as PFAS, are rapidly removed. In situ CAC treatments usually involve permeable reactive barriers (PRBs) placed between a PFAS source area and a potential receptor. Typically, a single PRB is engineered for decades of effective PFAS removal.

By removing PFAS from groundwater, the potential exposure is removed, and the risk to human health and the environment is eliminated. In this sense, the in situ CAC method treats PFAS the same way as its ex situ counterpart, P&T, filtering them out of groundwater. The vital difference between the ex situ and in situ treatment methods is in the filtering system’s location. Since the filtering occurs below ground, there is no generation of hazardous waste and no movement of PFAS from one locale to another, potentially recycling the problem. Further, the passive treatment approach relies on groundwater’s natural movement to bring the contamination into a CAC treatment zone. Thus, pumping infrastructure, long-term operation & maintenance, and fossil fuel usage are eliminated, making it a green and sustainable PFAS remediation technology.

Although the remediation of PFAS is in its infancy, numerous sites in the field have already shown two years of effective PFAS removal to achieve the cleanup goals, the longest-running treatment having demonstrated persistence for five years thus far (5). An independent, contaminant fate and transport modeling expert who has been studying this site has modeled probable longevity of the treatment at greater than 50 years. In addition to PFAS, the in situ CAC treatment approach has successfully treated other organic contaminants in groundwater and protected drinking water sources at hundreds of sites worldwide.

REFERENCES

- 15683PFAS_web.pdf. Accessed Sept. 21, 2021. www.awwa.org/Portals/0/ AWWA/ETS/Resources/15683PFAS_web. pdf?ver=2019-11-12-133836-883

- Interstate Technology and Regulatory Council. PFAS Remediation.; 2020. Accessed Oct. 29, 2021. www.youtube.com/watch?v=2OEeJ9qR9nA

- Tsang W, Burgess DR, Babushok V. On the Incinerability of Highly Fluorinated Organic Compounds. Combustion Science and Technology. 1998;139(1):385-402. doi:10.1080/00102209808952095

- Gribkoff E. Bennington professors say NY incineration caused toxic contamination. VTDigger. Published May 4, 2020. Accessed Oct. 28, 2021. https://vtdigger.org/2020/05/04/bennington-professors-say-ny-incineration-caused-toxic-contamination/

- Carey GR, McGregor R, Pham AL-T, Sleep B, Hakimabadi SG. Evaluating the longevity of a PFAS in situ colloidal activated carbon remedy. Remediation Journal. 2019;29(2):17-31. doi:https://doi.org/10.1002/rem.21593