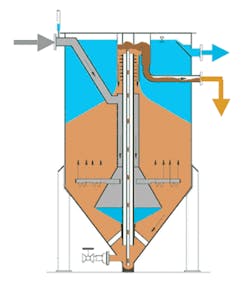

Click here to enlarge imageIn the system, feed is introduced at the bottom of the filter and flows upward through the sand bed bottom. Solids are trapped in the sand bed and the filtrate exits over an effluent weir. The sand bed, along with the accumulated solids, is drawn downward into an airlift pipe. Compressed air, introduced at the bottom of the airlift, draws the sand into the airlift. As the sand is airlifted, rigorous scouring actions removes the impurities which are then separated in the washbox chamber. The cleaned sand is redistributed on top of the sand bed, allowing for an uninterrupted flow of filtrate and reject (backwash) water.

The continuous operational design results in a relatively stable hydraulic headloss, making it an excellent choice for upgrading existing systems and lends itself well to gravity flow situations. The continuous nature of the filter also eliminates process interruptions and results in constant filtrate quantity and quality.

The Centra-flo design allows for physical-chemical and biological treatment or a combination.

With continuous backwash moving bed filters the simplicity of design results in minimal operational and maintenance requirements. There are no moving parts so maintenance and wear is minimized. There is no need for flow control valves, splitter/boxes, or backwash controls. The design also reduces plugging and does not short-circuit or clog.

Additionally, unlike batch processes, pre-treatment requirements are not necessary (settling, air-flotation, etc.) as the system can accept higher-than-normal suspended solids loading rates.

Upflow sand filtration has been used successfully in a variety of applications in the wastewater industry, including turbidity reduction, algae removal, denitrification, phosphorus removal, and treatment tertiary treatment for wastewater reuse.