Pilot plant with ceramic flat membranes on a golf course in St. Wendel, Germany.

Membrane technology has gained considerable attention in the wastewater treatment industry during the past decade. Advances in membrane technology continue to improve effluent water quality, reduce investment costs, and increase efficiency in sewage plants upgraded with treatment systems using polymer membranes.

Polymer membranes are well established in the field of wastewater treatment even though disadvantages such as restricted back-flushing behavior and indispensable chemical cleaning to prevent bio-fouling are well known. Until recently, economic alternatives to polymer membranes remained unavailable.

For the first time, the German company ItN Nanovation is testing its ceramic flat membranes, Nanopore®, in a small sewage pilot plant with the intention of developing a stable membrane bioreactor system (MBR), which is easy to operate, clean and maintain.

Ceramic filters offer good back-flushing behavior up to six bar, stability within the complete pH range from 1 to 14, and lifetime stability. Nevertheless, ceramic membranes were never discussed as a serious option to polymer membranes because of their high costs, unfavorable correlation between filter area and volume (weight), and availability of economically interesting sufficient quantities of filter systems.

ItN Nanovation produces Nanopore in its Halberstadt manufacturing facility for ceramic membranes with a capacity of up to 100,000-m2 filter area. The combination of a new fabrication technology with this capacity enables the company to reduce the price of ceramic membranes and produce them in sufficient quantity for large-scale wastewater applications.

The pilot plant is located at a golf course with an adjacent restaurant in St. Wendel, situated in southwest Germany. In 2006, a hotel will be built to expand the golf course facility and the pilot plant will treat wastewater from the resort. The pilot plant can be adapted to handle a higher capacity of wastewater (50 to 150 population equivalents (pe)).

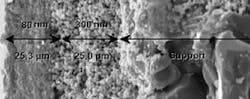

The ceramic flat membrane (width x thickness: 1100mm x 6,5mm) consists of a multi-channel filter element with 21 inner channels (diameter of 3mm). The flat multi-channel element is coated with a 80-nm pore size membrane based on nanotechnology.

Support and membrane are made of alumina, which is inert in a wide pH range between pH of 1 through 14. The bursting pressure of the membrane lies above 10 bar and the top of the hydrophilic membrane is smooth in order to obtain an easy-to-clean membrane surface. This membrane is designed for use in a MBR system that must be easy to clean and maintain. The rigid ceramic body of the membrane ensures that back-flushing can be accomplished without any pressure limitations (up to 6 bar) to remove surface formations (bio fouling). In the pilot plant, the ceramic sheets are potted in the module. The company is designing single flat membranes for future applications to simplify exchanges.

Pilot plant

In March 2005, the pilot plant began operating in St. Wendel. The ceramic filter area of 33m2 cleans the wastewater of 71 pe from the restaurant, located nearby the golf course. The core of the MBR consists of the ceramic flat membrane Nanopore with pore sizes of 80nm. The membranes are arranged in modules with 86 ceramic flat membranes with approximately 11m2 of filter area. The size of the module is 1,200 x 600 x 150mm (length x width x height); the distance between the flat membranes is 7mm. The rack construction allows easy enlargement of the filter area by adding modules to the rack. The aeration tubes for coarse bubble aeration are located below the rack ensuring an efficient aeration at low energy costs because the stack system allows the aeration of all modules above with a constant aeration area. The pretreatment of the MBR step is comparable to conventional sewage plants as a 3-mm screen is used. The activated sludge container contains 20,67m3.

Flat ceramic membrane with 80nm pores on the membrane layer on the outside of the filter.

Engineered with a total solids (TS) content up to 15 g/l, the pilot plant treats 8m3 of wastewater per day. The microbiological parameters of the effluent water remain significantly under the limits required by the EC directive 76/160 for recreational water, so the treatment plant yields process water of extraordinary quality. The German company KEN GmbH of Neunkirchen, Germany, is providing engineering and planning support to the project.

After six months in operation, the small-scale sewage plant continues to produce effluent that complies with EC directives, even though a constant operation modus has not yet been reached. The amount of wastewater averages 2m3 per day with a TS of 7g/l. Both results could increase because the amount of wastewater is low. The pilot plant can be expanded in capacity once the quantity of golfers and hotel guests increases. ItN Nanovations’ engineers expect that long-term operations will change from the current situation once wastewater volume increases and operational parameters change in order to maintain reliability.

Permeation occurs at low pressure (200-250 mbar) and back-flushing is working at a high level with 1 bar for 100 seconds every quarter of an hour. Company engineers determined the operational range of the flat ceramic membrane after conducting long-term tests with a pressure between 125-450 mbar, frequency of back-flushing every 40 minutes for half a minute up to 1,4 bar. These parameters reach a netto-fluxbetween 4 to 27 l/m2h depending on transmembrane pressure (TMP). Consequently ceramic flat membranes achieve flux rates in wastewater that are comparable to polymeric membranes.

Rack of MBR with three modules.

By September 2005 the pilot plant did not need a mechanical on-air or chemical cleaning. The flux ranges from 5 to 10 l/m2 h. Long-term tests in the company’s biological laboratory indicated that average flux rates of 15-20 l/hm2 in the pilot plant can be expected.

Investigations on the quality of the effluent water were conducted, specifically on the presence of faecal streptococci, coliform organisms, faecal coliform organisms and salmonella, according to the EC directive 76/160 for recreational water. None of these organisms have been detected in the effluent water, which will eventually be recycled for use in garden irrigation and toilet flushing.

A scientific research program, carried out by ItN Nanovation, is focusing on different operational parameters. In the following 18 months a systematic investigation of cleaning parameters will take place in which different cleaning methods (in-situ, on-air, ex-situ) will be compared in detail. In this regard, the chemical properties of the ceramic material offer new and improved possibilities with respect to the choice of chemical purification agents, concentrations and processing time.

The microstructure of the flat ceramic membrane shows coarse support, middle and top layer.

So far the membrane unit is working with continuous aeration being responsible for 60 percent of the operational costs. The analysis of air-cycling should reduce these expenses significantly. Scientific studies will further emphasize the system management of the ceramic filter because both laboratory tests and the start-up of the pilot plant have proven that the operation of a ceramic-enhanced MBR differs strongly from a conventional plant. Higher TMP and longer back-flush intervals can be realized, resulting in an increasing netto flux. Further research topics include variation of pore size and its influence on the retention of bacteria. In addition, the optimization of the engineering design is fundamentally important, including the exchange of individual flat membranes in the module.

Authors' Note

Olaf Binkle, PhD, is head of the research and development department of ItN Nanovation in Saarbrücken, Germany. Gerhard Braun and Kay Gabriel are process engineers for ceramic filter systems, and Ralph Nonninger, PhD, is the managing director of ItN.

ItN Nanovation provides nano-engineered solutions applying high quality nanoparticles. The tailor-made particles can be used for innovative ceramic products in the field of catalysis, surface finishing, sensor technology and ceramic tube and flat membranes, and are manufactured in one of the most modern facilities for ceramic filters in Europe. The company maintains its headquarters in Saarbrücken and a production facility in Halberstadt. Website: www.itn-nanovation.com.