Custom Pumps Guard New Orleans Against Flooding

The City of New Orleans and surrounding area are well below sea level - and sinking. Controlling flood waters is a serious business, especially when you're bordered by the mighty Mississippi and threatened by Gulf Coast Hurricanes. Huge flood control pumps from ITT Industries' A-C Custom pump unit are standing guard, protecting this region from flooding.

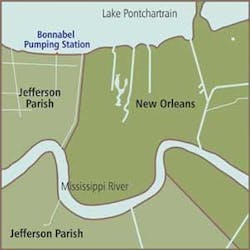

The entire New Orleans area, including adjacent Jefferson Parish, has a topography much like a saucer. This area is surrounded by levies, so every drop of water that comes into this "saucer" - by any means — including rainwater, by infiltration under the Mississippi levee, or through the sand strata from Lake Pontchartrain — has to be mechanically lifted out.

"Because the city is built on a swamp, the soil dries out, decomposes and subsides, increasing our drainage problems," said G. Joseph Sullivan, General Superintendent of the Sewerage and Water Board of New Orleans. "There are now sections of New Orleans that are 8 feet below sea level and sinking."

Moving water out of this topographic saucer requires a complex system of open and below-ground canals. These canals end at a series of very large capacity pumping stations housing enormous horizontal and vertical pumps from ITT Industries.

In New Orleans, the total capacity of these pump stations is approximately 42,000 cubic feet per second (CFS) or a little over a billion gallons an hour during rain load.

"It's not unusual that we'd have a full house at almost every station in the system," Sullivan said.

The horizontal and vertical pumps installed in New Orleans' pumping stations run anywhere from 50 to 100 hours per year. During some wet years, however, the pumps have run up to 200 hours. Most of these stations have redundant, ancillary equipment to ensure that the pumps will run during power loss.

"We have about 28 horizontal pumps in the system and we've only taken the cover off of one of them," Sullivan said. "The first large ones were installed back in 1912."

Ali Pirsalehy, P.E., Director of Pumping Stations for Jefferson Parish, says that. "Presently we have a pumping capacity in terms of CFS per acre of about .5 CFS per acre on the east bank of the Parish."

"With planned improvements, we should have something close to .75 CFS per acre, which is equivalent to pumping out about .75 inches an hour of rain," Pirsalehy said.

In Jefferson Parish, the capacity of the major pump stations vary from 2,000 CFS to 5,000 CFS. In the east bank of Jefferson Parish there are five major pump stations while in the west bank, there are about 14 major pump stations.

One such station is the Bonnabel Pumping Station on Lake Pontchartrain where there are three horizontal and two vertical A-C Custom pumps. The vertical pumps have a capacity of 135,000 gpm. The higher volume horizontal pumps have a capacity of 500,000 gpm.

ITT Industries currently has in excess of 50 pumps operating in Jefferson Parish and New Orleans and is now working on a project for Jefferson Parish that will include up to 11 horizontal pumps.

Custom Pumps

Each pump manufactured by ITT Industries' A-C Custom Pump unit is custom-made and meets the specific hydraulic requirements of each station. The size and capacity of the pumps dictate the size of the station as well as the total desired pumping capacity based on the drainage area served by that station.

Jerome Pepper, President of Pepper & Associates, an engineering firm that has designed and built pump stations for New Orleans, notes that, "First we develop a preliminary plan for the layout of the station, the discharge basin, and the intake basin.

"Based on the theoretical layout, we provide these plans to an independent model testing laboratory, who then constructs a model to maybe 1/10 or 1/9 the size. They then perform a series of tests to see if our design is hydraulically efficient."

Once a design is selected, it's up to A-C Custom Pump to furnish a pump that meets the engineer's design criteria, both for the head conditions and the CFS capacity it's required to deliver.

Billy Blackwell, Director of Construction Programs for Brown Cunningham Gannuch, an engineering firm that has designed and built pump stations in Jefferson Parish, says that, "We're concerned about pumping capacity as well as the maintenance, operation and longevity of the stations."

The horizontal pumps are 11 feet in diameter. Because they cannot be shipped whole, they are brought to the site in a number of pieces. All of these pieces have to be aligned, fitted and assembled. A-C Custom Pump provides an erection engineer who has all of the technical knowledge to assist the contractor in assembling these pumps.

"Because of their size, they can't be taken out for repair, so the design and manufacture of the pump requires them to be built to last a lifetime," Blackwell said.

The horizontal pumps have a low head, high capacity - moving large volumes of water a short distance. The rotating assembly of the horizontal pumps are installed above the water level and therefore, are protected from rusting as well as making them very easy to maintain.

"A-C, from our experience, has always had a very large technical staff who could address any questions that we posed to them," Pepper said. "They come down and work with you when you're installing the pumps, supervise the installation and answer any assembly problems and address all questions."