Pump Slump? Considerations for Upgrading Drive-Ends on Pumps

By Heinz P. Bloch, P.E.

The term "upgraded pump" somewhat unofficially describes a fluid mover designed beyond just soundly engineered hydraulic efficiency and modern metallurgy. An upgraded pump benefits water processors and water consumers alike. Further, upgraded pumps avoid risk areas in the mechanical portion commonly called the drive-end.

Why Some Insist on Better Pumps

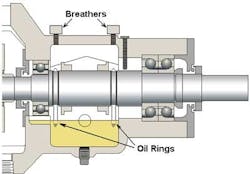

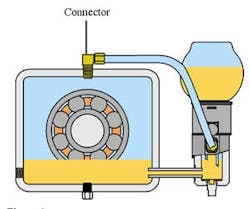

If your facility has pumps that incorporate the drive-end shown in Figure 1, you may be interested in its vulnerabilities or risk areas:

- Oil rings are used to lift oil from the sump into the bearings.

- Back-to-back thrust bearings are not located in a cartridge.<

- Bearing housing protector seals are missing from this picture.

- Although the bottom of the housing bore (at the radial bearing) shows the desired passage, the same type of oil return or pressure equalization passage is not shown near the 6-o'clock position of the thrust bearing.

- There is uncertainty as to the type or style of constant level lubricator that will be provided. Unless users specify the best available product, a pump manufacturer may simply provide the cheapest one.

Our considerations are confined to lubrication issues on process pumps with liquid oil-lubricated rolling element bearings. The great majority of process pumps used worldwide fall into this category. Small pumps with grease-lubricated bearings and large pumps with sleeve bearings and circulating pressure-lube systems are not discussed.

Lubricant Application

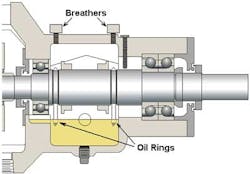

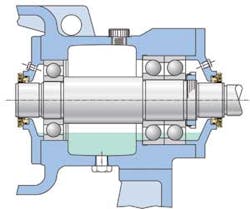

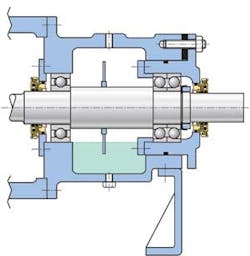

Probably the oldest and simplest method of oil lubrication consists of an oil bath through which the rolling elements pass during a portion of each shaft revolution (see Fig. 2). However, at high speeds, this may cause the lubricant to heat up significantly. Therefore, a widely-used rule-of-thumb calls for oil rings (see Fig. 3) or flinger discs (see Fig. 4) when DN, the product of shaft diameter (inches) multiplied by revolutions-per-minute (N), exceeds 6,000.

Oil Ring Vulnerabilities

Yet oil rings, sometimes called slinger rings, are rarely (if ever) the most reliable choice of lubricant application. They often tend to skip around and even abrade, unless the shaft system is truly horizontal, ring immersion in the lubricant is accurate, and oil-ring concentricity is near-perfect.

That is why reliability-focused purchasers often specify and select pumps with flinger discs. To accommodate flinger discs, bearings need to be cartridge-mounted. Here, the effective bearing housing bore (i.e., the cartridge diameter) must be large enough for insertion of a solid stainless steel flinger disc of appropriate diameter.

Bearings and Bearing Housing Protector Seals

For decades, pumps that conform to the stipulations of API-610 (American Petroleum Institute) have incorporated two thrust bearings mounted back-to-back, as depicted in Figures 1, 2 and 4. This allows selecting bearings with either the same or, for technical reasons, slightly different load contact angles.1

But moisture and dust often enter bearing housings at the shaft protrusion through old-style labyrinth seals or lip seals as airborne water vapor or water from hose-down operations. Contaminants can also enter through simple breather vents or traditional-style constant level lubricators. An upgraded "closed" constant-level lubricator (see Fig. 5) avoids ingress and ensures that pressures in bearing housing and vapor space below the oil-containing bulb are the same.

Finally, unless the rotating equipment is provided with suitable bearing housing seals, an interchange of internal and external air (called "breathing") takes place during alternating periods of operation and shutdown. Bearing housings "breathe" in the sense that rising temperatures during operation cause air volume expansion, and decreasing temperatures after shutdown cause air volume contraction. Open or inadequately- sealed bearing housings promote this back-and-forth movement of moisture-laden, contaminated air.

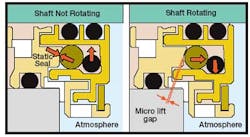

To stop this breathing and resulting contamination, there should be little or no chance of communication between the housing interior air and the surrounding ambient air. Old-style seals, however, may unintentionally allow an O-ring to touch a sharp-edged groove (see Fig. 6). In contrast, advanced-style bearing housing seals (see Fig. 7) incorporate large cross-section shut-off rings, which contact a wide and well-contoured surface. Because pressure equals force divided by area ("psi"), there is low pressure at standstill and virtually no pressure during operation. At standstill, no fluid passage is possible between vapor space inside a bearing housing and surrounding outside atmosphere.

There is low risk of rotor-stator contact because the mass-symmetrical rotor is clamped to the shaft with two O-rings. This imparts good stability and resists "rotor wobble." The right bearing protector seal can improve life and reliability of rotating equipment by protecting lubricating oil cleanliness.

Conclusions

Pump failures are costing industry and consumers. Upgrading the drive-end is often both feasible and cost-justified. A reasonable set of minimum requirements for reliability- focused users might include:

- Advanced versions of bearing protector seals for both the inboard and outboard bearings. Lip seals are not good enough and neither are old-style rotating labyrinth seals.

- As a matter of routine, the housing or cartridge bore must have a passage at the 6-o'clock position to allow pressure and temperature equalization and oil movement from one side to the other of the bearing. Note that such a passage was shown in Figure 1 for the radial bearing but was overlooked on the thrust bearing set.

- With proper protector seals, flinger discs and balanced constant level lubricators, breathers (or vents) are no longer needed on bearing housings.

- Bearings should be mounted in suitably-designed cartridges, and abrasion-prone loose slinger rings (oil rings) should be avoided.

- Suitably-designed flinger discs should be selected and secured to the shaft whenever the oil level is lowered to accommodate the need to maintain acceptable lube oil temperatures (i.e., for pumps operating with DN-values in excess of 6,000).

Reference

1. Bloch, Heinz P., & Allan R. Budris. Pump User's Handbook: Life Extension, 4th Edition, Fairmont Press, Inc., 2013.

2. Bloch, H.P. Pump Wisdom: Problem Solving for Operators and Specialists, John Wiley & Sons, 2011.

About the Author: Heinz P. Bloch is a mechanical engineer, author and consultant. He has been granted 7 patents dealing with high-speed machinery improvements and has authored 18 books on practical machinery management topics and oil mist lubrication.