Water Connections: Controlling Odors in Wastewater Treatment Ponds: Three Successful Approaches

Three successful approaches

Operators have several options for controlling odors in wastewater treatment ponds: increase aeration; apply chemicals to the water; apply perfume to the air. However, these solutions are often expensive and not totally effective. Another alternative — floating wastewater mixers — has emerged as an economical, effective solution for controlling odors in many wastewater ponds, including equalization ponds, deep-storage industrial ponds and anaerobic ponds.

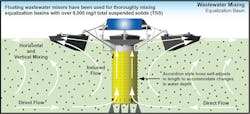

An equalization pond in front of a wastewater treatment plant acts as a shock absorber by temporarily holding excess inflow during rain events until the water can go through the treatment plant. Without thorough mixing, the organic solids entering the equalization pond will tend to settle to the bottom. Over time, the anaerobic digestive process occurring at the bottom of the pond can create ongoing odor problems.

By keeping the solids and water thoroughly mixed, solids move to the plant instead of settling out. The detention time of both the water and the solids becomes too short for the anaerobic process to ever pick up any momentum. And without anaerobic digestion occurring, odor problems are averted.

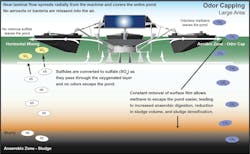

Anaerobic Ponds

Some wastewater treatment ponds (i.e., waste sludge storage ponds in activated sludge systems) are purposely designed for anaerobic digestion and thus produce sulfides and odors continuously throughout most of the pond depth. To eliminate odors emanating from these ponds, operators can maintain an “odor cap,” an oxygenated layer of water at the surface of the pond. When sulfide gas bubbles rise, they are instantly oxidized to non-odorous sulfate as they pass through the oxygenated odor cap.

Floating wastewater mixers are an ideal solution for creating an odor cap. Their adjustable intakes can be set at a desirable depth according to the particular needs of an application (usually 1–3 feet) and their 360-degree flow pattern reaches in all directions to the edge of the pond or reservoir.

Deep Industrial Ponds

Some industrial wastewater ponds, including mining ponds and oilfield wastewater ponds, can be quite deep (30–50 feet) and may contain mostly mineral and salt-based wastewater (i.e., boiler blow-down water from a power plant). In these types of ponds, sulfate is introduced with incoming water and other minerals. In the anaerobic environment at the bottom of the pond, some sulfate is converted to sulfide and becomes trapped in the cold, high-salt, high-density water at the bottom. When the pond “turns over” (usually spring and fall) and goes into full mixing mode, sulfides can be released into the atmosphere.

An effective odor control strategy is to deploy one or more floating wastewater mixers with the intake set all the way to the bottom. The deep, dense water containing dissolved hydrogen sulfide is continuously drawn up to surface where it is depressurized and vented into the atmosphere. WW

Medora Corporation is exhibiting at WEFTEC.19, booth 651. Learn more at medoraco.com.