Vertical Pumping: Bigger Isn't Always Better

By Michael T. Myers

For a lower cost, highly efficient solution for low speed, high horsepower, vertical pumping applications, think smaller. Using planetary gearing and standard, low-pole-count motors offer a very good alternative to traditional high-pole-count motors. This article will examine design criteria and advantages of vertical gearmotor technology as well as applications that could benefit from this technology.

In today’s business environment, everyone is striving to reduce costs and improve energy efficiency. High-flow, low-head vertical pumping applications such as cooling water, wastewater, irrigation, flood control and desalination have traditionally relied on low-speed pumping systems that use high-pole-count synchronous or induction motors. By choosing newer vertical gearmotor technology, facilities can reduce capital costs, cut maintenance, improve efficiencies, and increase system reliability.

Size Matters

High pole count motors designed to achieve the torque required for low-speed applications require considerable material content, making them inherently very large and costly. A vertical gearmotor utilizes planetary gearing to increase the torque and slow the speed of a more standard low-pole-count motor. The result is a much smaller pump drive package weighing 30 to 60 percent less than the high-pole solution. Not only is the integral vertical gearmotor package a compact solution but it also eliminates alignment issues between the motor and the gearing component. Along with cutting capital expenditures for the pump driver, the smaller, lighter vertical gearmotor package can result in sizable cost savings on foundation, support structures, enclosures, and other civil works associated with pumping projects.

In addition, high-pole-count synchronous and induction motors typically have longer lead times and higher maintenance costs than low-pole motors. Due to the size and complexity of these motors, the choices of repair facilities for large high-pole-count motors is also limited.

Improving Efficiency

The practice of using high-pole-count induction motors results in a drastic reduction in efficiency and power factor. Using synchronous motors will provide high efficiencies and power factors but are a significantly more expensive option than induction motors in both capital and maintenance costs.

When single reduction planetary gearing is used to increase the torque of a low-pole-count, high-speed motor it does so while maintaining a very high efficiency. Typically, losses are less than 1 percent. The power-dense design uses a sun gear and three to four planet gears to divide the power into multiple contact points within a small envelope. All this contributes to a smaller, lighter, less costly package while maintaining gear efficiencies of approximately 99 percent.

More Control for Optimized Performance

Impeller speed is an important factor in determining the operating point of the pump system. Pump performance and reliability is directly related to operation at the Best Efficiency Point (BEP) for the pump. Centrifugal pumps should be selected to operate at or near the manufacturer’s design-rated conditions of head and flow, referred to as BEP. There is only one BEP for optimum operation of a pump. Any pump operated at excess capacity will surge and vibrate, creating bearing and shaft seal problems as well as requiring excessive power. When operation is at reduced capacity the radial thrust on the rotor will increase, causing higher shaft stresses, increased shaft deflection, bearing problems, seal problems, vibration and axial shaft movement. Continued operation in this mode will result in accelerated deterioration and may result in pump failure. Therefore, it is important to select the proper output speed to optimize pump system design.

When using a motor alone, the base operating speed is fixed by the discrete number of poles in the motor and the voltage frequency. However, with a vertical gearmotor, the output speed is a function of the base motor speed and the gearing ratio. A gearing ratio can be selected to fix the pump impeller speed to the desired RPM at the low-pole-count motor’s base speed. This improves system efficiency, pump performance, and reliability.

Soft Start for Improved Performance

In many high-flow pump applications, the pump system needs to be controlled during starting and priming to ensure adequate torque is supplied during start up and prevent damage from water hammer. This is commonly done by using valves to close a portion of the discharge piping then starting the motor, followed by slowly opening the valves to prime the system. Another alternative to control the application is through an expensive VFD drive.

A vertical gearmotor drive provides an alternative by including an integral mechanical hydroviscous clutch within the planetary gear set to soft start the pump. The hydroviscous clutch is disengaged until the motor starts and comes to full speed unloaded. After the motor attains full speed, the clutch is engaged slowly to accelerate the load under a tightly controlled acceleration curve, minimizing the impact on the power system and providing the soft start needed to prime the pump system.

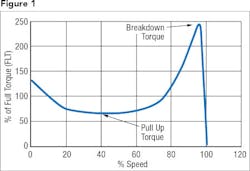

A benefit to achieving base motor speed under no load is the ability, when starting a pump, to utilize the high torque of a standard motor design that is available when the motor is operated near base speed. This can prevent the need for a special motor design to maintain a high motor torque as it moves through the pull-up torque portion of the motor curve. These special motor designs are more expensive, have higher inrush currents, are less efficient, generate additional heat, and can limit the number of available starts per hour.

When compared to traditional high-pole-count motors, choosing vertical gearmotor technology for low-speed, high-horsepower vertical pumping applications will help reduce costs, improve efficiency, and increase system performance. All of these advantages prove that bigger isn’t always better.

About the Author: Michael T. Myers is the global business manager of controlled start transmission (CST), large, and specialty gearing for Baldor Electric Company.