Understanding Pump Cavitation and Its Impact on Pump Reliability

By Allan R. Budris

When recently reading a new pump association publication on wastewater treatment plant pumps, I was surprised to find the statement, “Cavitation starts in pumps when the pump net positive suction head available (NPSHA) falls below the pump net positive suction head required (NPSHR).”

Some 35 years ago when I first observed cavitation in the eye of a pump impeller during an NPSH test, I could see that the eye was completely clouded with cavitation vapor at - and well above - the pump NPSHR. I subsequently determined that cavitation actually starts in a pump at values from two to 20 times the NPSHR. Even back then, I was surprised by the number of Hydraulic Institute (HI) members who believed that cavitation started at the pump NPSHR.

Despite having covered this topic in many of my prior WaterWorld columns and articles, as well as my “Pump User’s Handbook - Life Extension,” a more detailed description appears to be in order.

NPSHR

According to the HI, the pump NPSHR is actually the total suction head (static plus velocity head) above the liquid vapor pressure, where enough cavitation is created in the pump to sufficiently block the impeller inlet, reducing the head generated by the pump by 3 percent. This pressure drop makes the NPSHR value easier to measure.

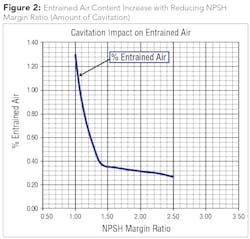

This also means that if the NPSH available to the pump is equal to the NPSHR, the actual head developed by the pump would be 3 percent lower than the published head (which is based on sufficient suction pressure). It can take NPSH margin ratios of up to 1.3 at the best efficiency point (BEP) and 1.7 at low flow rates just to reach the full published pump head. This is why the HI and other pump organizations now often refer to the pump NPSHR as the “NPSH3%.”

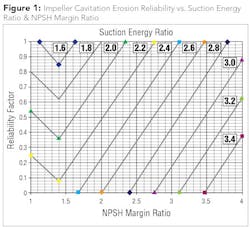

Start of Cavitation in Pumps

As mentioned previously, cavitation actually starts in a centrifugal pump from two to 20 times the NPSHR value, depending on the pump design and energy level, with the average value being around 4 to 5 times the NPSHR. This does not mean that the NPSHA must be four to five times the NPSHR to avoid any damage from the cavitation that exists in the pump below these values. There should, however, be a reasonable margin above the NPSHR value to avoid a loss in performance and the possibility of pump damage under certain conditions.

Cavitation Pump Damage

Since cavitation exists in all pumps at and above the NPSHR (and for some pumps up to 20 times the pump NPSHR), a large number of installed centrifugal pumps are operating with some degree of cavitation. So the question then becomes, will this existing cavitation cause any physical damage to the pump or reduce its performance?

I have seen a stainless steel pump impeller destroyed by cavitation in as little as three months. Pump damage typically comes in the form of erosion of the impeller blade surfaces from the cavitation bubble collapse when they reach a higher static pressure within the impeller (which is above the liquid vapor pressure). The force from these implosions can also damage the bearings and/or mechanical seals due to the associated vibration. The following lists a number of factors that determine if a pump will be damaged by cavitation and the severity of any such damage.

- Liquids, such as hydrocarbons, that are actually composed of non-homogeneous liquids - each with different vapor pressures - generate less damage than water, which has only one (condensing) vapor pressure for a given temperature.

- Cavitating liquids that contain abrasives/solids will generate more damage than just the imploding cavitation bubbles because the action of the implosions will accelerate the abrasives towards the impeller surfaces. Under abrasive/solids conditions, even low suction energy pumps can experience cavitation/erosion damage.

- Cavitating liquids that are corrosive to the pump materials of construction will experience more pump damage than would be experienced with either the corrosives or cavitation alone because the softer, corroded surfaces will be more easily damaged by the imploding cavitation bubbles - again, even with low suction energy pumps.

Performance Impact of Cavitation

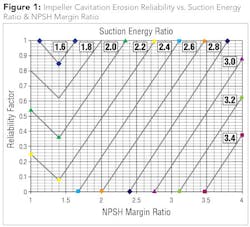

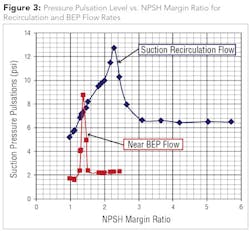

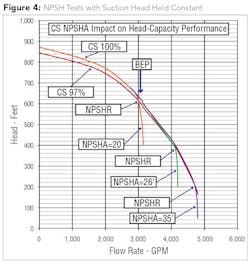

Figure 4 shows how the pump head capacity curves fall off with fixed NPSHA values, as the flow rates push the pump closer to and below its NPSHR values. Any dissolved air that is liberated as entrained air during the generation of the cavitation bubbles will further add to this cavitation flow blockage, further reducing the pump head.

In addition, excessive amounts of entrained air could also enter the mechanical seal faces, which may cause dry running, damage and/or failure of these faces.

NPSH Margin

To further help readers navigate the complex aspects of pump cavitation, I provided more detailed NPSH margin guidelines in my two-part Dec. 2012 and Jan. 2013 columns.

Conclusion

As detailed previously, the pump NPSHR is not where cavitation actually starts in a centrifugal pump, even though the contrary is stated in various industry publications. Because of this, and the fact that some cavitation exists in a large percentage of pumps, a reasonable NPSH margin is required to avoid the loss of pump performance and possible damage. To further guide users, I - in addition to the Hydraulic Institute - have provided helpful NPSH margin guidelines.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles