Taking the Devil Out of the Details

By Manuel de los Santos

On the island of Tasmania off Australia's southeast coast, the AquaMB System from Aqua-Aerobic Systems Inc. is utilized as an alternate to membrane biological reactors (MBRs) in the town of St. Helens. This technology was selected due to the comparable effluent quality to the MBR system and lower cost of ownership.

A Multi-Barrier Approach

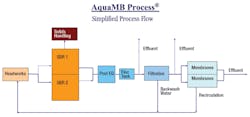

The multi-barrier membrane system integrates biological treatment, cloth media filtration and microfiltration into a single process with resulting savings in membrane area of greater than 50% compared to a typical MBR configuration.

The plant is designed to treat an average flow of 0.4 million gallons per day (mgd) of domestic sewage from the local community. In addition to the savings in lifecycle cost, the multi-barrier process provides flexibility and ease of operation. These are the main reasons why this process was selected over MBR. Operators take advantage of this flexibility, especially since St. Helens is a coastal holiday destination, and the population typically increases by up to 50% for a two-month period in summer.

Process Description

Raw wastewater comes into the plant from St. Helens. The influent pump station sends the wastewater through a grit removal system and a 6 mm perforated influent screen. If the 6 mm screen needs to be taken offline for maintenance, there's a backup 20 mm bar screen available onsite.

* Consists of a 2-basin sequencing batch reactor,

cloth media disk filter, and external membranes.

The secondary process includes a dual basin AquaSBR system designed for biological nutrient removal (BNR). Alkalinity is supplemented in the biological reactors in the form of Soda Ash. Effluent from the sequencing batch reactor (SBR) goes to a post equalization basin and a flocculation tank, before entering the tertiary filtration.

To supplement the biological phosphorus removal of the SBR, the operator can add alum into the biological reactors, the flocculation tank and/or the post equalization basin, if required.

The clarified effluent of the SBR is pumped from the post equalization to a flocculation tank and then flows by gravity through the cloth media of the stationary hollow disks. The filtrate exits through a hollow shaft that supports the individual disks and flows to the effluent channel.

Tertiary effluent flows into a pump station and is then pumped to the external membranes. Due to high quality effluent from the cloth media filter, with a total suspended solids (TSS) concentration of less than 5 mg/L, the membrane area is reduced significantly. The St. Helens plant includes 1,300 m² of membrane area. The membrane effluent goes through UV disinfection prior to discharge.

The treated effluent is discharged into nearby St. George Bay, which is utilized for sensitive aquaculture and thus has specific effluent quality requirements (see Table 1).

Plant Operation

Based on the multi-barrier approach of the process and the high quality effluent from each of the processes, operators are able to discharge directly from the filter or membranes. Although not available in this site, an option could be added to discharge directly from the SBR, by-passing the filters and membranes. The plant had a test period that allowed it to discharge less than ultimate effluent quality. The operators took advantage of the multi-barrier and were able to commission the plant in stages and still meet effluent targets.

During the test period, the operators were able to run the dual basin SBR system in a single basin mode, utilizing one of the SBR basins as a Pre-EQ basin. The plant received an average of 36% of its design flow. In the Pre-EQ/SBR mode of operation, however, this equates to an average of 72% of design flow. At this time, the BOD load was 39% – which equates to 78% of the design loading in this mode of operation. As expected, there was a gradual increase in loads as more tourists arrived over the summer months.

Daily measurements of key influent and effluent parameters were performed during the test period, proving compliance during the course of this evaluation (see Table 2). All the effluent requirements were met during the test period. In fact, effluent quality exceeded the treatment required to the point that all parameters of the ultimate effluent required were met. Addition of alum was minimal during the test period; but, to demonstrate the capacity of the system to reduce the total phosphorus, alum was dosed into the flocculation tank, after the test period. The alum dosing regime was determined to achieve a final 0.1 mg/L effluent TP value while meeting effluent quality limits for all other parameters.

Chemicals for the membrane cleaning processes include citric acid, sodium hydroxide and sodium hypochlorite. The recommended cleaning intervals are every 30-60 days for membranes in an MB system. Still, the low loading, as well as the mechanical cleaning regime of air scour/reverse filtration and enhanced flux maintenance (which uses a small amount of sodium hypochlorite) provided sufficient cleaning to return the transmembrane pressure to an "as new" condition.

Conclusion

The new multi-barrier system provided the town of St. Helens with flexible operation during commissioning, allowing its wastewater treatment plant to discharge from each one of the processes to St. George Bay. The system exceeded the testing period requirements, as well as demonstrated reliability on meting the more stringent requirements. In addition, it proved to require less cleaning than expected due in part to the high quality effluent from the cloth media filter. Finally, the AquaMB system demonstrated itself to be a viable alternative to the more popular MBR technology.

Author's Note: Manuel de los Santos is a senior applications engineer for biological processes/membranes at Aqua-Aerobic Systems Inc., based in Rockford, Illinois, USA, near Chicago. He holds a master's degree in sanitary and environmental engineering from the Universidad de Cantabria, Spain, and a bachelor's degree in civil engineering from the Universidad Nacional Pedro Henriquez Ureña, Santo Domingo, Dominican Republic. Contact: +1 815-639-4456 or www.aqua-aerobic.com

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles