TOCs Away: Heathrow's Reed Bed Treatment Takes Off

Heathrow has embarked on a natural way of storing and treating heavily-contaminated storm water at its Mayfield Farm Treatment Facility by upgrading to Forced Bed Aeration (FBA). Initial data shows that, as well as dramatically increasing its treatment capacity, the airport has also enhanced its environmental performance.

By Tori Sellers.

Say 'Heathrow' and runways, terminals and radar-topped control towers come to mind but much of its 1,200 hectare footprint is grassland, landscaped areas and natural habitats.

Off-airport land is managed to maximise biodiversity and minimise the airport's impact on nature with the plan accredited by the Royal Society of Wildlife Trust's Biodiversity Benchmark Award. That green ideal is set against a backdrop of minimising the impact of winter operations on the environment and the inherent costs of storing and treating the resulting wastewater contaminated by deicing fluids

Arctic environments are consistent in their harsh weather pattern whereas London's varies wildly. In the winter of 2012/13, 25 events were forecast but only five delivered heavy snowfall. These unpredictable weather patterns make it difficult to manage biomass which is the critical success factor in natural processes.

Increasingly severe winters of recent years across Europe and America has led airport operators to review their storm water treatment strategies as part of their Winter Operations plans to support flight safety and schedule continuity.

The desire to avoid airport closures and travel delays has fuelled a surge in the use of deicing fluids - partly due to an increase in severe winter conditions and also due to the increased concentration of the deicer used on aircraft. Waste streams generated from airports are typically from de-icing activities, aircraft wash down, fire fighting training and the terminals themselves. Airports have large areas of concrete and tarmac which collect rainwater which becomes contaminated as it mixes with fuel and glycol residues.

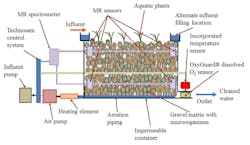

The run-off from the southern catchment of Heathrow airport had been stored and treated by the Mayfield works, which included a constructed wetland system installed in 2001. It comprised 36,000 m3 of storage: a primary reservoir, a floating reed bed section, a balancing lagoon and twelve constructed wetlands, each 0.5 m deep.

The original treatment wetlands at the airport were designed to remove deicers containing glycols using anaerobic processes with a design loading rate of 590kg (Biochemical Oxygen Demand) per day (BOD/d).

Heathrow evaluated the plant's treatment efficiency and whether it was fit for purpose. It was struggling to cope with all the challenges of harsher winters while maintaining optimum output and discharge compliance. The solution called for a step change in treatment capacity.

Evaluating and optimising

Heathrow wanted to optimise its existing treatment system which was designed to store and treat much lower contaminant loads based on data from the 1990s. It was decided that it needed a natural treatment system to attenuate and treat the flow of storm water before discharging to the local watercourse.

The old system was the right size physically for the volume of water but increased use of deicer over the past few years had overloaded the system so that oxygen and nutrient availability were the limiting factors.

Coupled with the fact that the run-off is nutrient-poor, this resulted in a low microbial count in the system. This meant it was struggling to maintain treatment performance, leading to effluent having to be tankered off-site for treatment.

A Forced Bed Aeration (FBA) system was recommended by ARM, following results from an installation across the Atlantic, at the Buffalo Airport in New York. The $9 million, full-scale, airport wastewater treatment system was next to the runway but it had no risk of "bird strike" (collisions between birds and planes) as it had been planted with grass and has no areas of open water.

The proposed re-design of the treatment works at Mayfield would use the entire, existing infrastructure which included retro-fitting aeration systems into the constructed wetlands. The design target was to remove a minimum of 3,500 kg of BOD/d.

Glycol removal trials

Before an effective treatment system could be implemented, a trial was set up in the winter of 2009-10 to monitor the contaminant load and to test the constructed wetlands' ability to remove deicer components. Three of the existing constructed wetlands were taken off-line.

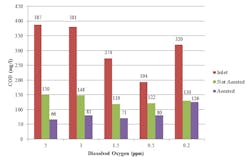

Bed A was re-engineered and the aeration system (FBA) retro-fitted and switched on. Bed B was re-engineered with FBA but not aerated. This was so that it had the same level of disruption as Bed A to ensure comparative results and Bed C was the control bed so it stayed as per the original layout.

All three beds received the same storm water and were monitored to show storage and treatment capacity in the three systems.

Trial, results and start of treatment works

The trial demonstrated the wetland system was dealing with an actual load of 1,900Kg BOD/d which was three times the original design load. As a result, in October 2010 BAA commissioned ARM to optimise the Mayfield Farm Treatment Facility including retro-fitting aeration into the existing wetland treatment systems.

Based on the results of the trial, twelve beds at Mayfield Farm were retro-fitted with FBA technology. No new assets needed to be built as the existing infrastructure of lagoons and constructed wetlands were re-used.

The data for the whole new system is currently being collated but, even with very harsh weather conditions, Heathrow has improved its removal rates by a factor of fourteen since using FBA.

Managing the solution - online instrumentation

Extensive research and development into effective wastewater treatment consistently shows that an integrated system – which is capable of adapting to challenges - is the most effective solution. However, even the most efficient wastewater treatment system will require management to ensure it continues to effectively store and treat contaminated run-off.

It will need to be adjusted - with minimal time demanded from airfield operations staff - to meet varying treatment demands as the climate fluctuates so widely.

Natural wastewater treatment systems require management of nutrient and bacteria levels to ensure there is enough biomass to treat the contaminants. At Heathrow's Mayfield Farm Treatment Site, online instrumentation and controls were installed to help treatment process integration.

Great power, great responsibility

Airports will need to commit to integrated, sustainable, wastewater treatment solutions to meet the demands of best and worst deicing scenarios.

Heathrow has raised its game by reducing the airport's environmental impact and will cut operating costs for many years to come. Since installing FBA, three major benefits can be noted at Heathrow. The first is that by re-using the original wetland treatment facility, Heathrow's only needed to upgrade the system.

Secondly, the airport's environmental team is able to control and monitor the system's performance remotely using a SCADA system, requiring minimal on-site intervention.

Finally, after planting 80,000 reeds, Heathrow has made a huge contribution to meeting its biodiversity action plan by maintaining habitats for birds, bats and the insects on which they feed.

As Heathrow's environmental operations manager, Russell Knight, says: "This facility allows us to continue fulfilling our commitments to running Heathrow responsibly and efficiently."

And when it comes to an airport that's in charge of hosting 70 million passengers arriving and departing each year, responsibility is one matter where Heathrow cannot afford to cut corners.

Tori Sellers is director at ARM Group. For more information on the installed system, visit: www.armgroupltd.co.uk.