Small Footprint for Sewage Processing

Implementation of a municipal wastewater treatment plant in Kuwait utilizing an advanced bio-filtration system with numerous advantages over activated sludge systems

By Dr. Hans Badreddine

In response to local regulations, the Ministry of Public Works in Kuwait City initiated a program to assess the problem of implementing a sewage treatment plant within 100 meters of a residential area at the Hutten Plant in the South Sourra neighborhood of Kuwait City. The problem was on two fronts. First of all, there must be minimal odor emissions. Hydrogen sulphide (H2S) must equal 0 mg/L. The second issue has to do with the handling and general nuisance of sludge within such a close proximity to a residential neighborhood.

Goals and Objectives

The primary goal of this study was to determine how to minimize odor and at the same time virtually eliminate sludge.

The objectives were to identify the latest technologies that can resolve these underlying problems and to identify an overall solution that will also fulfill all the requirements of the Ministry of Public Work in Kuwait City.

Identifying the Problem

A comparison between Activated Sludge Sewage Treatment and a patented Bio-Filtration technology called the Hans BioShaft® System was conducted. As a result of implementation of this municipal wastewater treatment plant system utilizing an advanced bio-filtration system, numerous advantages over activated sludge systems were demonstrated and the Kuwaiti Ministry of Public Works decided to employ the technology. Among those advantages were:

As it can be assembled and operational quickly, the technology also is ideal for emergency situations and military uses.

Activated Sludge Technology

Activated sludge treatment has many problems associated with it. Activated sludge plants are expensive to build and occupy substantial land areas. They rely upon utilization of large and costly settling tanks and aeration basins to “settle out” and “digest” biosolids in the waste stream as well as the introduction of bacteria, chemicals, or membranes to treat the sewage and reduce the amount of leftover sludge.

High energy costs are involved in operating most activated sewage treatment plants, due to pumping oxygen into aeration tanks, operating moving screens or filters, etc. Activated sludge treatment plants also produce significant amounts of sludge, that must be further treated and disposed of at tremendous costs. Due to the Hutten plants close proximity to residential areas sludge treatment couldn’t be implanted onsite.

Most importantly the local odor emission regulations requires that no gas or odor emissions may be released within 100 meters of residential areas. The only way that activated sludge treatment can resolve this is through the addition of an odor control system. This won’t only be expensive in equipment, maintenance and manpower, but will also consume a large amount of space and energy.

The Solution

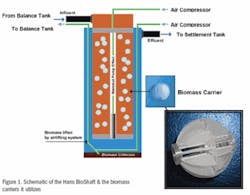

A BioShaft plant produces minimal odor without the construction of an odor control system. This technology encapsulates a sophisticated biofilm and bio-filtration system within a shaft as shown in Figures 1 and 2. The system relies on bacteria that occur naturally in the waste stream to rapidly filter, breakdown, consume and ultimately remove up to 95% of biosolids from the waste stream. The unique design facilitates both the aerobic and anaerobic digestion of waste materials, while at the same time creating and maintaining particularly robust bacteria that aggressively consume biosolids.

Despite its compact size, the bio-filtration system provides a huge surface area upon which bacteria and oxygen can consistently and effectively interact with and remove biosolids from the waste stream. By contrast, other sewage treatment plants rely upon the random coupling of bacteria with oxygen molecules, pumped into huge tanks, for their digestion process. This requires that the sewage influent be retained in large settling and aeration tanks for many days (10-22) in order to be treated.

The unique features of this system dramatically reduce retention time required to treat sewage to hours rather than days and make the compact treatment plant very efficient and effective. The overall result is a more efficient and effective plant that’s much less expensive to build and operate and much smaller in size, as shown in Figure 3.

null

Conclusion

The Hans BioShaft System technology not only met the requirements set forth by the Kuwaiti Ministry of Public Works but also provided other numerous benefits as noted above and avoided many of the problems created by activated sludge technology. All data produced by the system for the Hutten Plant in Kuwait met the ministry requirements for secondary treatment. Most of the results show tertiary quality.

Author’s Notes:

Dr. Hans Badreddine is president of BioShaft Water Technology of Carlsbad, California, USA. It’s sewage processing systems are made using the Hans BioShaft®Turbine that is at the heart of the wastewater technology. It was developed in the Netherlands in 1994 and improved upon by Dr. Badreddine. Patented in the United Kingdom, a patent is pending in the United States. To date, there are over 30 of these wastewater treatment plants in use worldwide. Contact: 760-901-5404 or www.bioshaft.com