Using Global Positioning Systems To Track Workforce Attendance

by Scott Prewett

When it comes to adopting new technologies like mobile workforce tracking and automated timekeeping, utilities have probably lagged somewhat behind many industries. But that picture is changing fast. Those who serve the water and wastewater industries are rapidly discovering new, easy-to-use, portable systems for tracking assets and attendance, and enjoying the substantial cost savings and efficiencies that go with them.

The latest, and perhaps the most dramatic, addition to jobsites is the Global Positioning System, or GPS. Originally developed for the military, GPS works off a system of satellites. It was made available for civilian use years ago, but only recently have GPS-enabled devices become affordable and popular with consumers. They've also become a valuable tool in the contractor's mobile management arsenal.

Asset Tracking with GPS

We're all familiar with how delivery companies use GPS to track truck fleets and packages in real time. These “active” GPS systems enable dispatchers to view maps showing vehicles, delivery status and other information. When a package arrives on time, GPS has played a part.

As utilities have discovered, if you can track delivery trucks with GPS, you can track the location of your equipment to help you manage and maintain it more efficiently. As a result, GPS systems are already being used to track utility assets. For companies with a lot of equipment at multiple locations, the use of GPS for asset tracking continues to increase in popularity.

Workforce, Payroll and Cost Tracking with GPS

For the utility industry, GPS has as much application to workforce attendance, job and cost tracking as it does to equipment tracking. GPS is a big step in the evolution of mobile workforce management: tracking employees by time, jobsite and cost code continuously throughout the day is an easy way for a company to boost its operational efficiency.

Workforce attendance tracking with GPS extends the capabilities of mobile attendance systems already in use. Some systems travel to jobsites with crews, replacing handwritten timesheets and manual tracking of cost codes, among other time- and money-saving features.

Accurate Attendance, Accurate Costs

Central Backhoe & Utilities, Ltd. (San Antonio, TX), a utility contractor with about 25 employees, has five to six crews moving around to multiple locations on a given day. Central relies on mobile attendance tracking to get accurate hours from workers.

Lillian Sanders, Central's accountant, found that attendance tracking resulted in significant savings on every one of the company's crews. “Before,” she explained, “everyone reported identical start times and I knew it wasn't right. Now it's accurate. The difference is unbelievable.”

Some systems, like ExakTime's JobClocks, travel to each jobsite. With this system, workers clock in and out using color-coded Keytabs that they keep on their own keyrings. The Keytabs can be assigned to identify specific cost codes within a job, which helps with job costing and controlling workers compensation. Other Keytabs can track travel time.

The JobClock stores the data, and at the end of the day or week, attendance records can be downloaded to a PDA or smartphone. The Internet can also be used to transmit records into the office.

Exaktime's proprietary software, TimeSummit, can generate separate reports for employees, jobsites and activities. The system can transfer the information into accounting software, such as QuickBooks.

One benefit of such a system is that it eliminates the time-consuming task of entering attendance records manually. The system even calculates overtime automatically.

Return on Investment

For companies that utilize mobile attendance tracking, the real bottom line becomes apparent very quickly: mobile attendance tracking pays for itself, and more, in cost savings and efficiency.

“Even 10 minutes a day, across 20 guys over a week, is a big savings,” said Lee Rodriguez, Chief Estimator for Empire Pipeline (Carlsbad, CA).

Mike Vagi, manager of Boone Services Inc. (Baton Rouge, LA), said, “When we started mobile attendance tracking, I just wanted to save our foremen the hassle of doing handwritten hours. I got my investment back in under a month.”

Adding GPS to Mobile Attendance Tracking

GPS and worksite attendance tracking can be combined to track worker attendance as it occurs and can verify workers' locations.

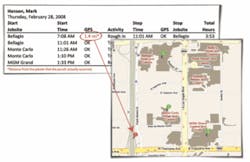

PocketClock/GPS, for example, turns a Windows® PDA into a portable timeclock. With GPS capability built-in, it can track not only when workers clock in and out, but also where. It can track crews, their locations, who is in the crew, track labor by cost codes, and it allows the foreman to add new jobsites spontaneously.

Data from the device can be transferred from the field to home base. The software enables users to see a map of the region that pinpoints jobsites and graphically displays attendance data. Printed reports breaking down the work that was performed can be used for a number of tasks, such as payroll or estimating new jobs.

Combining GPS with automated timekeeping makes it possible to get information about each jobsite, know who has been at each site, address problems and reallocate resources as needed.

Another valuable aspect of GPS-equipped systems is that you can define the geographic boundaries of a jobsite. With a ‘geofence' in place, it is easy to track whether a worker is within a pre-defined range of a jobsite when clocking in or out.

Is GPS for Everyone?

Yes, according to Vagi, whose family-run employer has 55 employees. “You can get down to the penny on your labor and job costs. If you can track man-hours accurately and save on taxes, workers comp and labor, that's good. And that's where these systems help you.”

Nowadays, utilities that want to start saving on job costs can choose from an array of mobile attendance tracking systems. Regardless of when companies make the leap, mobile attendance tracking, and GPS, are here to stay.

About the Author:

Scott Prewett is the Chief Technology Officer for Exaktime Inc., designing time and attendance systems for use by the construction trades.