Conn. utility removes 45% of THMs with clearwell intervention

While the addition of chlorine is one of the safest and most effective means for water disinfection, under certain circumstances chlorine in combination with naturally occurring organic compounds in water can lead to the formation of undesirable disinfection by-products (DBPs).

One of the most common DBPs is a family of volatile compounds called trihalomethanes (THMs) which are regulated in the United States to a level of 80 parts per billion (ppb) by the U.S. Environmental Protection Agency. As water age increases (the time from water treatment in a plant to ultimate use), THM formation progresses with water utility operators closely monitoring their system’s locational running annual average for THMs.

In the past several years, Aquarion Water Company had been monitoring their system’s THM formation and attempting to lower them through treatment and distribution system changes in Stamford, Conn. THM formation typically peaks as water temperatures increase seasonally and with increasing water age. During this time Connecticut was also experiencing severe drought which resulted in a reduction in water use and a subsequent increase in water age in their system.

Aquarion engineers decided that reducing THM formation in the Laurel High Service Clearwell at the Stamford Water Treatment Plant (WTP) would eliminate concerns of elevated THM formation in the distribution system served by the WTP.

The Laurel High Service Clearwell is a below grade water tank that has a volume of 1.5 million gallons with about 50 percent daily turnover. PAX Water Technologies (PAX) of Richmond, Calif. was selected for the project to strip THMs from the Laurel High Service Clearwell.

Several design modifications were made to accommodate the unique features of the Laurel High Service Clearwell. Two 0.5 HP PAX Variable Angle Mixers were chosen to ensure a strong mixing profile throughout the tank despite its relatively low 16 foot ceiling height. The PAX Powervent® ventilation unit was sized at 1.0 HP to effectively break the Henry’s Law gas/liquid equilibrium and evacuate the tank headspace of THMs.

Additionally, the design software added a floating surface aerator to enhance mass diffusion of the various THM species from the water phase to the gas (air) phase. Finally, due to the role of the clearwell in plant operations, the equipment was installed in a phased fashion over a couple weeks without taking the tank down.

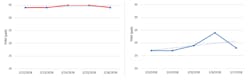

Aquarion Water Company and PAX Water Technologies agreed that for the addition of less than 20 HP and the described equipment scope, a removal goal of 40 percent of the THMs was achievable. Since THM removal percentages stay constant for the system as actual THM levels rise, the removal test was scheduled for January and February of 2018 and the system met the performance goals: Aquarion was able to achieve a 45 percent removal rate.