May the FORSe Be with You

Incorporated in 2014, the new city of Chestermere Lake is a suburb community of Calgary, Alberta. Like most of the local suburbs, it relies on the city of Calgary for final treatment of its municipal wastewater. Chestermere Lake pumps its wastewater several miles - from its collection system to one of Calgary’s treatment facilities - via force mains.

Odor and corrosion were serious problems, which led to the commissioning of a chemical treatment program that added a significant six-figure annual expense to the city’s operating budget. Per requirements set by the city of Calgary, the operating company responsible for the Chestermere Lake collection system needed to maintain a maximum hydrogen sulfide (H2S) level of 5 parts per million (ppm) at its monitoring station just prior to the plant. If odors exceeded the maximum limit, fines could be imposed on Chestermere Lake by the city of Calgary.

The existing chemical program was acceptable at reducing odors but was expensive and required supply tanks and frequent truck deliveries of the product, which in some cases was undesirable for the neighborhood residents. Untreated, the H2S odor levels would be in excess of 300 ppm.

Anue Water Technologies (AWT) was contacted regarding the use of one of its mobile demonstration trailers to pilot test the effectiveness of oxygen as the sole treatment for odor control. The FORSe2 oxygenation system was installed at a lift station to achieve two objectives: test the effectiveness of the oxygen technology for reduction of odor at the force main discharge; and determine the capacity (size) of the system required to provide effective odor and corrosion control.

Sulfide Chemistry and Method of Action

AWT’s FORSe2 system is designed to control odor and corrosion within wastewater systems by oxidizing sulfur-containing organic compounds so that they exist in a form that is no longer malodorous, corrosive or otherwise detrimental to system and environmental health. These compounds, particularly H2S, are typically associated with the anaerobic bacteria ‘slime layer’ found in the parts of the system that have low to zero oxygen present at any given time, such as the inner walls of piping.

Infusion of oxygen into wastewater will increase dissolved oxygen (DO) levels, which will in turn convert the slime layer into an aerobic layer and eliminate its sulfur production. By impeding and reversing the creation of H2S through oxidation with oxygen, the FORSe2 technology is able to significantly decrease the negative effects of H2S.

Treatment Equipment

Anue’s Mobile Demonstration Unit #1 was used for the trial. The unit consists of the following major components:

- Air compressor

- Pressure swing absorption oxygen concentrator

- Compressed air receiver tank

- Control valves for oxygen metering

- Force main infuser installed into discharge force main

- Supporting instrumentation: flow meter, oxygen concentration monitor, solenoid valves

- Integral control system

Treatment and Testing Methodology

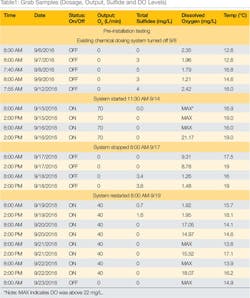

Treatment of the force main occurred from September 14 to 22, 2016, at varying rates of oxygen output (see Table 1) in order to observe the collections system’s response to various treatment levels. The system was stopped for 48 hours (Sept. 17-19) to observe whether H2S levels would remain low without treatment.

Samples were taken twice per day from a discharge point manhole approximately 2 kilometers downstream of the lift station. Samples were analyzed for DO, temperature and dissolved sulfide concentration. In addition to grab samples, an OdaLog was placed in the manhole for the entirety of the demonstration.

It is interesting to note that there was dissolved oxygen detected even in the samples prior to treatment. This is a common occurrence at locations with a “waterfall” effect at the force main discharge sampling point, as there was at the pilot’s lift station force main discharge manhole. However, after treatment a very high residual DO is maintained through the end of pipe. This occurs even with the reduced treatment level of 40 L/min. Further, dissolved sulfide was no longer detected with the system operating.

Test Results

Before oxygen treatment, the average H2S level at the manhole downstream was 59 ppm and reached a maximum of 483 ppm around 12:47 pm (see Table 2). During the first two days of treatment (70 L/min), the H2S level dropped to an average of 2.4 ppm, with a peak level at 23 ppm.

When treatment was temporarily stopped (Sept. 17, 8 a.m.), the H2S average increased slowly during the stoppage period, to 8.1 ppm that day and 34 ppm the following day (average values).

On Sept. 19, the system was restarted, with oxygen addition at 40 L/min. The average H2S level was slowly reduced from 28.7 ppm to 1.17 ppm by Sept. 23. The delay effect is very typical when introducing oxygen into the force main.

Like the gas phase H2S level measured in the manhole, sulfide has the same effect when there is a high level of oxygen in the water. In general, if the DO level is above 2 mg/L, the sulfide level will be close to 0 mg/L. As shown in Fig. 1, there is no sulfide if the average DO is higher than 2 mg/L.

Conclusion

As is clear from the data, the H2S and sulfide levels in the manhole during the treatment are almost eliminated if there is a high level of DO. The initial dose was 70 L/min, which proved to be too much for the flow. The revised dosage (40 L/min) was almost adequate to treat the system with an average water temperature 16.7°C.

Ultimately, based on the demonstration, a FORSe2 system with an output of up to 55 L/min oxygen would provide effective treatment and the desired results at the discharge manhole during all phases of the year. In all but the hottest months, the system would operate at a level well below the maximum output.

The successful demonstration pilot virtually eliminated the H2S odors without the on-site storage or delivery logistics required by the chemical program. In addition, the city and EPCOR were able to ‘test drive’ the actual oxygen generating equipment, the effectiveness of the oxygen gas infusion system and the proprietary software for on-site and remote monitoring and control. Following the conclusion of the demonstration and validation of the odor control solution on a full-flow force main test, a permanent system was purchased.