Effluent Diffusers Improve Water Quality

Foreseeing industry growth and overall city expansion, the City of Cedar Rapids, IA, Wastewater Treatment Plant sought a new permit that would increase the total allotted daily discharge and allow for the release of higher amounts of regulated compounds. However, the city already was having difficulty meeting some of the required river flow concentration levels set forth by the Iowa Department of Natural Resources. In order to obtain a better permit, the plant first needed to effect a significant reduction to the pollutant concentrations being produced by its current level of discharge.

"In the winter, during low river flow, it was hard to meet the required concentrations of certain pollutants, such as ammonia and biological and chemical oxygen demand," said Operations Specialist Chris Hatch. "We were meeting our water quality regulations but foresaw the increase in city industry would make that an even harder goal to reach in the next 10 years."

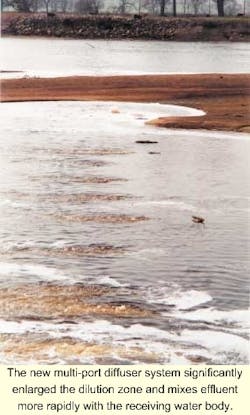

The city consulted engineering firm Howard R. Green for a means of lowering dilution-zone pollutant concentrations without further restricting the current discharge operation. The firm concluded that the city's existing outfall line could be redesigned into a multi-port diffuser that significantly would enlarge the dilution zone and mix the effluent more rapidly with the receiving water body. An effluent diffuser would be a more reliable and cost-effective option than altering the treatment process or installing a second outfall line.

The new Cedar Rapids diffuser system is comprised of a total of 73 ports spaced evenly across the length of the outfall pipe. Attached to each port is a TideflexRegistered effluent diffuser valve with a RedflexRegistered rubber riser and a 45-degree RedflexRegistered rubber elbow, all provided by Red Valve Company. The unique duckbill design of the diffuser valves creates a pressure drop across the valve that maximizes the velocity of the discharging effluent and increases the speed of mixing, reducing pollutant concentrations at each discharge point.

Red Valve's diffuser package offers several benefits that have maximized the efficiency of the Cedar Rapids system. Because the products are constructed entirely of elastomers, they will not rust, break or erode. The duckbill design also prevents backflow into the header pipe as backpressure from the receiving water body effects drop-tight sealing.

Because Cedar Rapids continually is expanding, Hatch knew that a system working efficiently at the time of installation eventually would have to be upgraded. Howard R. Green and Red Valve worked together to engineer a diffuser system that would meet the city's current needs and still allow for future increases in capacity without any major redesign requirements.

More of the valves were installed than necessary under current flow conditions. Red Valve vulcanized closed a portion of the diffuser valves to limit the number of ports in operation, thereby maintaining adequate velocities within the line at the plant's current rate of flow. When the rate of flow increases with growth, the valves can be slit open to increase overall system capacity.

To test the efficiency of the city's new system, Hatch took aerial shots of the diffuser zone with an infrared lens to determine the rate of dissipation. Before installation of the system, the heat at the single discharge point did not dissipate for over one mile. After installation, this same heat generally dissipated within 100 yards of each operating discharge port.

With this much more efficient and environmentally friendly means of discharging its wastewater effluent, the City of Cedar Rapids was able to obtain a better permit.

"The new permit regulations are much easier to meet," Hatch said, "and they allow the city a lot of future growth."