Stormwater management without the additional infrastructure

By Sergio Pino-Jelcic and Casey Whittier

Wastewater utilities are under increasing pressure to manage wet weather conditions more effectively with existing infrastructure. Stricter regulatory requirements to handle stormwater flows and the effects of climate change are amplifying this challenge for municipalities. Numerous facilities’ planning efforts are now looking into ensuring flexibility and resilience for a wide range of heavy rain events.

Wastewater treatment plants must be equipped to handle variable pollutant loadings and large fluctuations in flow. During wet weather events, secondary clarifiers are hydraulically stressed, increasing a facility’s vulnerability to biomass washout, which can lead to rapid deterioration of effluent quality and disruption of a plant’s biological treatment process. Conventional methods for handling high weather flows have historically included constructing and operating treatment plants grossly oversized during normal weather flows or constructing large costly wastewater storage basins to hold the overflow so it can be treated through the plant over time.

Alternatively, in the last decade, high rate sidestream treatment has been implemented as an option to treat wet weather flows. In this scheme, excess flow is bypassed around the main plant and treated on the side. Then it is blended with secondary effluent. This approach requires new infrastructure and the proper regulatory framework to allow for blending.

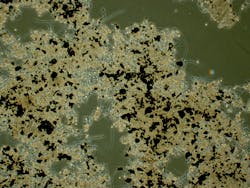

Figures 1 and 2. Top: Biological floc (MLSS) ballasted with magnetite. Bottom: Typical biological floc. By infusing magnetite into either a chemical or biological floc, settling rates are increased, allowing better and more reliable clarification.

Ballasted Clarification

Clarification is a key component of effective wet weather management strategies. Performance of all types of clarifiers is determined, in large part, by the settling velocity of particulate suspended solids. When dealing with stormwater flows, the faster the settling rate, the better.

Ballasted settling and clarification has been shown to be an effective solution to handling wet weather flows. Magnetite ballasted clarification technology was introduced to the wastewater industry in the late 1990s. A few years later it was successfully implemented in activated sludge. Since then, ballasted activated sludge has been selected by numerous utilities to provide rapid and reliable settling clarification for their secondary treatments.

Ballasted activated sludge treatment can be implemented into a plant’s existing tankage without the need for physical expansion. The technology uses fine (10–40 microns), dense particles of magnetite, a fully inert iron ore mineral, to significantly increase the settling velocity of mixed liquor suspended solids (MLSS), thus enabling facilities to manage wet weather flows in all types of activated sludge using existing tankage and without bypassing biological processes.

Magnetite

Magnetite has several key properties that make it ideal as a ballast material for wastewater treatment clarification. First, as an iron ore, it is abundant and readily available. The material has a very high specific gravity (5.2), which allows it to increase the settling rate of MLSS floc, especially those with a poor sludge volume index (SVI). Magnetite is also hydrophobic, allowing it to bond well with biological floc (see Figs. 1 and 2).

When used as part of this ballasted settling technology, magnetite has NSF certification for compliance with drinking water regulations, which means it has no impact on the biology in secondary wastewater treatment. Unlike grit or sand, the magnetite specified for the ballasted clarification process is so fine that it has the consistency of talcum powder. Therefore, it does not cause abnormal abrasive wear and tear on a treatment system’s pumps, mixers, valves and other components. In fact, traditional ancillary mechanical equipment can be used with magnetite ballasted secondary treatment.

The Upper Gwynedd Township, Pa., WWTP has been using the process to handle wet weather flows since 2014.

How Magnetite Ballasted Activated Sludge Works

With the ballasted clarification technology, BioMag®, the activated sludge treatment system is ballasted to a ratio of approximately 0.7–1.0 lb of magnetite per pound of biological MLSS.

Magnetite is continuously recovered and recycled back to the biological system to keep the adequate inventory of ballast material in the bioreactors (see Fig. 3). A magnetite recovery system retrieves approximately 90–95 percent of the ballast from the plant’s waste activated sludge (WAS).

Because of magnetite’s ferromagnetic properties, it can be easily recovered by using rare-earth magnets. The core of the ballast recovery equipment, based on a design used for decades in the mining industry, consists of a rotating drum with an array of magnets inside. After the recovery drum, the recovered ballast is sent to a blending tank where it is blended with return activated sludge (RAS) — for conveyance purposes — and a small quantity of virgin magnetite to make up for the slight ballast loss. The magnetite feed system is designed utilizing either a silo or bulk bag storage mechanism. No direct operator contact with magnetite is required. Following blending, the recovered ballast is returned to the activated sludge system.

With the high settling rates of ballasted MLSS, the secondary clarifiers can now be operated at higher surface overflow and solid loading rates. Wet weather flows can be properly managed when the operators have an effective and reliable tool to push the clarifiers when hydraulic surges hit the facility. In addition, with the clarifiers operating at a much higher loading rate, this provides opportunities to run the biological treatment at a significantly higher biological MLSS for more treatment capacity in existing infrastructure. There are, for example, municipal wastewater treatment plants using this system that run at 8,000 to 10,000 mg/L MLSS (magnetite excluded). The process has shown treatment plants consistently achieve a SVI of less than 50 mL/g.

Example: Upper Gwynedd Township, Pa

Wet weather flows have been successfully tested in numerous full-scale wastewater treatment plant (WWTP) demonstrations of magnetite ballasted clarification. In Pennsylvania, the Upper Gwynedd Township WWTP has been using the process to handle wet weather flows since 2014.

“Our facility had long undergone pressure during peak wet weather flows,” Plant Superintendent Lee Honeywell said. “Our clarifier became a major bottleneck due to lack of solids separation.”

The existing plant was designed to treat an average daily flow of 5.7 million gallons per day (MGD) and a maximum monthly flow of 6.5 MGD, with a peak hourly flow of 12 MGD.

“We struggled to manage peak flows using the plant’s available tanks to hold and equalize the flow as much as possible,” Honeywell said. “Monitoring and control was a time-consuming, operator-intensive process during these periods of high-flow events.”

Initially, a full-scale, three-month pilot was performed at the plant to evaluate the BioMag system’s ability to adequately treat all flow (hydraulically and organically), as well as its capability to reduce total phosphorus (TP) below the plant’s foreseeable limit of 0.2 mg/L. The technology demonstrated stable, high-level treatment at elevated flows of 6+ MGD using half of the available clarifiers, which corresponded to full plant peak hourly flow of 12+ MGD.

In addition, magnetite ballasted settling allowed for stable, high-level treatment at high organic loading at the plant, comparable to 10,842 lbs per day, the maximum biological oxygen demand the plant was designed to manage. Total suspended solids (TSS) were less than 10 mg/L (monthly average) and less than 30 mg/L (maximum per day) during peak flows. The plant also achieved a lower effluent TP limit of 0.2 mg/L, achieved consistent nitrification and fully met its ammonia permit levels (summer 0.74 mg/L; winter 2.2 mg/L).

Full-Scale Operating Results

Since it was first installed in early 2014, the BioMag system has been successfully handling high wet weather flows and producing effluent with TSS concentrations below 10 mg/L and carbonaceous biological oxygen demand (CBOD) of less than 5 mg/L during these conditions. The system was installed without additional tankage, in-basin changes, flow diversion during construction, or any treatment interruptions.

In April 2014, the newly modified Upper Gwynedd plant passed the ultimate stormwater test — a once-in-a-lifetime, five-inch rain event. Almost all of the other WWTPs in the Philadelphia area were flooded, but the Upper Gwynedd plant experienced no problems.

High fluctuations in flow rates were experienced during 2014 and 2018 at the plant, with a mass peak flow of 16.9 MGD and an average flow of 2.6. But regardless of these frequent hydraulic surges, effluent TSS from the secondary clarifier was low, with an average TSS of 3.1 (see Fig. 4).

“The system has improved the quality and stability of the township’s effluent to the extent that the plant will be rerated to an annual average flow of 6.4 MGD, a maximum monthly flow of 7.5 MGD and a peak hourly flow of 22.5 MGD,” Honeywell said.

The Upper Gwynedd plant additionally completed two performance tests in which the treatment facility had to meet a 0.2 mg/L effluent phosphorus limit. It successfully passed these tests with an average effluent reactive phosphorus concentration of 0.09 mg/L and 0.11 mg/L. With only the addition of the magnetite ballasted settling technology, the township was able to avoid the expense of adding tertiary treatment and a secondary system upgrade to meet future limits.

Other Performance Data

Consulting firms recently participated in hydraulic stress tests conducted at four wastewater treatment plants (two in northern Texas, one in Tennessee and one in Ontario, Canada) and verified the clarifier loading rates and effluent quality out of the secondary clarifiers. The Texas and Ontario plants simulated peak flow events by recirculating plant effluent back to the secondary clarifiers during one-day trials (several flows were tested). The Tennessee plant was tested during an actual rain event.

Resulting data summarizing the clarifier stress conditions of the four plants (see Table 1) shows the instantaneous surface overflow rates (SOR) and solids loading rates (SLR) applied to the clarifiers, as well as the effluent TSS during the stress tests. In all four cases the loading rates were significantly higher when compared to conventional clarification of activated sludge. The effluent quality in all four trials exceeded the design team’s expectations.

Other full-scale plants in operation using the magnetite ballasted clarification process have also found benefit from the resilience that the process provides during heavy rain events. Hydraulic peaking factors as high as 6:1 have been reported, with effluent TSS concentrations below 10 mg/L.

The ballasted clarification system has demonstrated the ability to achieve up to 2-3 times the throughput of existing conventional activated sludge plants by improving settling rates and allowing the user to run at higher MLSS in the biological tanks of the activated sludge process. Significantly improved settling allows for increases in plant capacity and provides better effluent quality (comparable to tertiary filtration) utilizing a plant’s existing tankage. This high rate clarification strategy provides a cost-effective alternative to MBR, MBBR, IFAS technologies and conventional clarifier expansion.

Further Improving Site Evaluations

To further explore the advantages of magnetite ballasted clarification, a comprehensive solids flux test program based on the American Society of Civil Engineers (ASCE) Clarifier Research Technical Committee (CRTC) protocol was developed. The advancements achieved with this pioneering program have now enabled the use of State Point Analysis when evaluating clarifier capacity using magnetite ballasted activated sludge. Using this advanced analytical approach, bench tests can be performed on site to quantify the settling enhancement that can be used to better handle wet weather flows without the need for additional infrastructure. WW

About the Authors: Sergio Pino-Jelcic is technical sales manager for biological process equipment, and Casey Whittier is global product manager for ballasted settling technologies at Evoqua Water Technologies.

Circle No. 245 on Reader Service Card