Water 4.0: Reducing Energy Consumption with Advanced Data Analytics

Clean water is a basic human right. It’s also one of the most essential requirements for human health, environmental sustainability and economic development. But due to population growth, urbanization, climate change, and lack of proper water management, this vital resource has become scarcer than ever before. In order to meet the increasing need for clean water, societies will have to shift toward a more organic and environmentally sound water cycle. Instead of just discharging wastewater into the environment, it needs to be captured, treated, and distributed back to the consumer. This crucial cycle requires increased energy which results in an increased carbon footprint.

Water reuse and wastewater treatment are intrinsically energy intensive. They require moving large volumes of water with pumps and electric motors followed by treatment to meet stringent regulatory requirements. In conventional wastewater treatment plants (WWTPs), aeration is one of, if not the biggest, energy consumers in this process. Other significant energy consumers include filtration and disinfection processes. It is clear, however, that the industry must take serious steps in reducing the amount of energy it uses.

Evolving Treatment Approaches to Minimize Energy Consumption

Global interest in Industry 4.0 has accelerated digital transformation in the process industry, including water related industries, paving the way for organizations to truly minimize energy consumption. Many companies have engaged in technology pilots to explore options for reducing costs, increasing overall equipment effectiveness (OEE), and reducing energy use and its carbon footprint to conform to regulatory compliance. Additionally, in order to optimize treatment processes, they are looking into the use of data analytics to make better and faster decisions on a daily basis and looking into novel energy efficient treatment processes. An example is the use of anaerobic membrane bioreactors (AnMBR) which are used in WWTPs to separate and treat sludge from wastewater, generating biogas as a byproduct. The industry is also investigating the use of microbial electrical systems to generate electricity while treating wastewater with microbial fuel cells (MFC). However, this approach is still in its early stages of development. Other examples to optimize treatment processes include using membrane aerated biofilm reactors, improved disinfection and filtration, membrane technologies like ultrafiltration and reverse osmosis, and UV light.

Democratizing Data and Analytics Reduces Energy Consumption

For many years, process data has been captured and stored. All this data can be leveraged for continuous improvement of processes and to lower energy consumption. To some extent, data analytics is already utilized by major companies for their larger on-site energy issues, but traditional analysis methods require significant resources. They are typically time-consuming, centrally led data modeling projects and are less suited for process related optimization projects that require subject matter expertise. In recent years though, new self-service analytics tools have been developed that allow process experts to leverage a plant’s data to monitor and optimize their energy use themselves, taking their plants’ productivity to the next level of operation.

With self-service analytics, process experts can quickly access, search, and analyze their time series data to answer relevant questions on a day-to-day basis. They can generate and test hypotheses by using descriptive, discovery, diagnostic, and even predictive analytics. When data and analytics are democratized, subject matter experts can solve energy related process cases independently, without the help of data scientists. The process experts themselves can positively contribute to corporate goals to reduce energy consumption and its carbon footprint.

Advanced Data Analytics Optimizes Treatment Processes

Before starting any energy management project, it is crucial to first define the problem and identify the high energy consumers. Using descriptive analytics, process experts can benchmark optimal operating conditions. Such benchmarks or reference periods can then be used to assess cost saving opportunities and set priorities for optimization projects. Additionally, with discovery analytics, optimal operating conditions can be used to configure monitors and set alerts for process issues.

Here are a few ways experts can use self-service analytics to optimize operations:

- Leaks can be detected if levels in tanks decrease abnormally fast. When this happens, alerts can be sent to process experts.

- The data that is captured when flow control valves start to wear out or become plugged can be analyzed to give insights into this situation.

- Increased hydraulic head losses are caused when membranes become fouled. This change of behavior is captured in time-series data which can be identified in different operating windows in scatter plots generated by the data analytics software. These anomalies can be detected and used as a premise to prompt process experts in the field to take corrective action.

Overcoming High Input Variances to Create a Condition-Based Maintenance Schedule

In a wastewater treatment plant in Europe, process experts wanted to improve the maintenance schedule for the aeration elements of the biological wastewater treatment.

Since the aeration elements suffer from fouling, these elements needed regular cleaning. The goal was to transition the maintenance planning from a time-based schedule to a condition-based schedule.

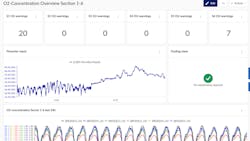

However, the high variance of input variables made it difficult to have a clear indicator. In order to overcome this hurdle, a data analytics tool was used to create a dashboard to monitor the oxygen concentration during the nitrification of the wastewater treatment (Fig. 1).

This visualization allowed the process experts to see if the aeration elements needed treatment and to plan accordingly, which lead to savings in both maintenance and energy costs.

Monitoring a Plant’s Pump Infrastructure

At another European treatment facility, process experts used an advanced data analytics tool to monitor the plant’s pump infrastructure. The engineers easily translated their process knowledge into monitoring criteria using the search functionalities of the tool. They looked for potential problems in the normal operation of the pumps, for example, using vibrations in a pump as an indicator of a malfunction. In case of high vibrations, alerts were set to notify the operators and the engineers of a problem. Additionally, process contextual information was automatically written on the asset. Once the monitoring was configured for all the pumps, a live dashboard was set up, which gave a clear visualization of every pump (Fig. 2).

The advanced data analytics tool was used to create a Gantt chart for an overall view of all the pump runs in a defined time period. Process experts then knew which pumps were running, which pumps had malfunctioned, and the frequency of pump problems (Fig. 3).

The Value of Subject Matter Experts

With increasing water demands and ever-evolving environmental regulations, the water industry is having to think of new ways to increase energy efficiency and optimize operations. New data analytics tools can be adopted to bring the subject matter experts to the forefront of the analytical process, by enabling them to analyze, monitor and predict process and asset performance in real-time. This strategy incorporates the precious insights these experts can offer, so they can significantly contribute to meeting the organizational energy reduction and carbon footprint goals. An added value is that these improvements come together with increased safety and improved overall profitability. WW

About the Authors: Daniel Münchrath is a data analytics engineer for TrendMiner. He has a degree in biochemical and chemical engineering, and brings the two worlds of industry and data analytics together.

Ruchika Tawani is a data analytics engineer for TrendMiner. She graduated with a chemical engineering degree from TU Dortmund, Germany. She is currently working for TrendMiner on their customer success team.