In July the international water community will once again gather at the Singapore International Water Week.

What can you expect from the bi-annual show this time?

By WWi magazine

In July Singapore will once again embrace the well-deserved title of being a “global water hub” and will welcome utilities, consultants, technology companies, academics – the global water community - to its city-state.

Returning visitors and industry veterans will be well versed on Singapore’s well quoted success story. However, first time visitors and industry newcomers will be amazed at how the nation of just 5.5 million people, one of the most water-stressed places in the world, is not thirsty.

Singapore’s success story

For 15 years now, Singapore has been transforming wastewater. Every day in Singapore, it is estimated that some 800,000 cubic metres of ultra-pure recycled water – called NEWater – is reintroduced into the system, supplying some 40 percent of the country’s total daily demand.

This enviable figure of 40 percent didn’t come overnight: Singapore has worked towards it, in the process building up its treatment network. Last year, the country’s fifth wastewater reclamation plant was opened. The 228,000 m3/day project was delivered by BEWG International, a subsidiary of Beijing Enterprises Water Group Limited and UES Holdings, under a Design-Build-Own-Operate (DBOO) contract awarded in 2014.

It is one of six DBOO projects between national water agency PUB and the private sector, also including the Keppel-Seghers Ulu Pandan NEWater Plant, SembCorp NEWater Plant. It’s important to note that NEWater is one of Singapore’s Four National Taps, which also includes local catchment water, imported water and desalinated water.

For the latter, desalination is expected to provide up to 85 percent of Singapore’s water needs by 2060. Once they are all complete, five desalination plants will meet the city-state’s water demand, expected to grow exponentially.

The fourth project – the Keppel Marina East development – is the first of its kind in Singapore and will be delivered under a Design, Build, Own and Operate (DBOO) model as a large-scale dual-mode desalination plant that can treat both seawater and freshwater.

Interestingly, depending on wet or dry weather conditions, water is channeled either from the Marina Reservoir or the sea to the plant, where it will be treated. Aesthetically, the development will be a sleek, modern design that breaks away from conventional water treatment treatments. It has been described as a “lush green gem”.

New developments

To help bring these developments together, this year the Singapore International Water Week (SIWW) will include several components, including: the Water Convention, Lee Kuan Yew Water Prize, Water Leaders Summit, Water Expo@City Solutions Singpoare, the Young Water Leaders Summit and others, including site visits.

Now in its 10th year, the event is known for helping to drive business opportunities and this year visitors can expect to hear updates on the Tuas Water Reclamation Plant and Integrated Waste Management Facility of the multi-billion Deep Tunnel Sewerage System Phase 2 project.

The Water Leaders Summit (WLS) will also feature a new forum - Environment & Water Leaders Forum: Closing the Loop - Catalysing a Resilient and Sustainable Future.

Water prize

The winner of the Lee Kuan Yew Water Prize 2018 is Professor Rita R. Colwell, who was credited for “discoveries and innovations” that “fundamentally changed the way the world things of water microbiology”.

As the 8th Lee Kuan Yew Water Prize Laureate, Professor Rita R. Colwell will deliver the Singapore Water Lecture on 9 July 2018. She will also receive the Lee Kuan Yew Water Prize at the Lee Kuan Yew Prize Award Ceremony and Banquet on the same night. www.siww.com.sg

Potable reuse will solve the world’s water problems

Speaking on World Water Day, Mr Ng Joo Hee, chief executive PUB, Singapore’s National Water Agency, said:

“On this World Water Day, it is a sad fact that a large swathe of humanity continues to be thirsty. Number six of the United Nation’s 17 sustainable development goals calls for ensuring the “availability and sustainable management of water and sanitation for all.

“When we consider that 40 percent of the world ‘s population do not have enough water, 1.8 billion drink from a source that is faecally contaminated and 2.4 billion lack basic sanitation – all the UN’s own numbers – achieving SDG 6 will surely require a gargantuan effort. Where do we start?

“Tiny Singapore’s way may just be how the rest of the world should be going. Singapore sits right on the equator, in the tropics, where it rains every other day. More than 5½ million people call Singapore home. The reality is that there is just not enough room in Singapore to collect and to keep all of the rainwater that is required to sustain the city-state. Because of this, Singapore is one of the most water-stressed places in the world.

“However, Singapore is not thirsty. And it is my contention that even the most water-challenged country can have enough water. The trick to successfully realizing SDG 6 is to think of water and sanitation as one whole, as two sides of the same coin, rather than as distinct and independent parts. Combining water and sanitation means endlessly recycling water, reusing it again and again.

“This is exactly how Singapore has been able to fully accomplish SDG 6 despite nature’s poor endowment. In Singapore, we believe that the H2O molecule is never lost; that water is an endlessly reusable resource. And when it comes to life-giving water, it is simply unacceptable that it should be thrown away after only one use. We have long been convinced that water can always be reclaimed and re-treated so that it can be drunk again. Incredibly, Singapore collects every drop of its sewage and turns much of it into drinking water again.

“PUB, Singapore’s national water agency, is a world leader in this. Today, PUB Singapore is, literally, able to transform waste water into sweet water for very little money. We have been doing this for more than 15 years...The potable reuse of waste water is particularly attractive because it provides us with a drought-resistant source of potable water. “And it is endlessly sustainable. The treatment technologies that are required are now commonplace. Their reliability and effectiveness are well-established and continue to improve by the day. Even better, and unbeknown to many people, making sewage potable actually requires, gallon for gallon, far less energy than desalinating seawater...the rest of the world has to make potable reuse a priority if we are at all serious about putting a dent in SDG 6. It is the most natural thing to do.”

EXHIBITOR HIGHLIGHTS

PWNT is unique in our formation and mission to make our parent company PWN’s over 96 years of experience and innovations in water treatment available worldwide. Our extensive R&D programmes focus on the development of efficient and sustainable solutions capable of treating a wide variety of water sources based on suspended ion exchange, ceramic membrane applications and advanced oxidation. All our solutions offer lower life cycle costs, higher efficacies and much lower environmental impact. We work closely with our clients to create optimal results and strongly believe in partnering with highly recognised universities and globally respected companies for continuous improvement.

Booth: L1-H28

ACCIONA Agua provides comprehensive solutions which contribute to sustainable development

in the water sector. The projects and contracts executed by the company since its creation contribute to treating, processing, reusing, desalinating and managing water for over 90 million

people in more than 25 countries on five continents, always to the highest standards of quality, innovation and sustainability. ACCIONA Agua has placed its name on over 400 drinking water and wastewater treatment plants and over 75 desalination plants. It also operates and maintains a full range of water treatment plants and provides end-to-end water services in over 180 cities.

Booth: B2-F16

Bürkert Fluid Control Systems is one of the world’s leading manufacturers of measuring, control and regulating systems for liquids and gases. Bürkert products are used in a wide range of industries and applications – ranging from breweries and labs to medical, bio-engineering and aerospace technology. With a portfolio of more than 30,000 products, Bürkert is the only supplier to offer all fluid control system components, from solenoid valves to process and analytical valves, from pneumatic actuators to sensors. With its headquarters in Ingelfingen in southern Germany, the company has a wide-ranging sales network in 36 countries and more than 2,500 employees worldwide.

Exhibitor Promotion

Innovative processes to unlock new markets

With an even more global vision, plus a firm commitment to innovation and the use of state-of-the-art technologies to launch its projects, ACCIONA Agua has been consolidated as one of the sector worldwide leaders.

Over the last years ACCCIONA has won its first contracts in countries such as the Philippines and Canada. It has also strengthened its presence in Latin America and the Arabian Gulf. Through the development and application of in-house technologies in state-of-the-art infrastructures for desalination, potabilization and wastewater treatment, ACCIONA Agua will make a key contribution to changing trends in desalination techniques.

It is moving away from older thermal processes such as MSF (multi-stage flash) and MED (multiple-effect distillation) towards reverse osmosis, for example with the Ras Abu Fontas desalination plant in Qatar.

desalination through reverse osmosis

Despite the abundant water resources in the Philippines, access to potable water is unequal in the country. A large part of the population opts for self-supply, which increases the importance of the future Putatan 2 Drinking Water Plant that ACCIONA Agua is now building in Greater Manila, in the southern part of the country’s capital city.

The plant, which will supply almost six million people with a capacity of up to 150,000 m3/day, will use reverse osmosis technology for the advanced treatment of raw water from Laguna de Bay, the biggest lake in the Philippines.

Meanwhile in Qatar, which is one of the richest countries in the world but has enormous water needs, thermal processes accounted for almost 100 percent of the installed desalination capacity in the country. This trend has been reversed with the two new large-scale reverse osmosis plants that ACCIONA Agua has already built. The two plants have a production capacity of 450,000 m3/day. Through milestones such as the start-up of the first phase of Ras Abu Fontas 3, which has started recently to produce water after just two years - making it the first large-scale desalination plant using reverse osmosis in Qatar - the change of paradigm in these processes in the region has already become a reality.

Meanwhile, ACCIONA Agua entered the Canadian market for the first time. In Saint John (New Brunswick) the company will renew the city’s water distribution system, the biggest in the province and the oldest in Canada. The contract includes the construction of a drinking plant, a storage facility with capacity for 75 million liters per day and a tank to provide a service to around 70,000 people.

In 2018, ACCIONA Agua has won a new contract in UAE, the Jebel Ali Desalination plant. This new Seawater Reverse (SWRO) Plant is being developed as a brown field seawater desalination plant and associated facilities, with the selected desalination technology being Sea Water Reverse Osmosis (SWRO).

This plant is expected to be commissioned by May 2020 and will have a total capacity of 182,000 m3/day.

Over thirty projects in Latin America

The water and sanitation sector has become one of the main drivers of development in Latin America, a continent where ACCIONA Agua has continued to consolidate its presence. Peru, Ecuador, Santo Domingo or Mexico are just some of the 12 countries in the region where ACCIONA Agua now operates. New projects for the coming years include the management of the integrated water cycle, the improvement of energy consumption, the overall development of plants and smart control systems, or research into state-of-the-art technologies are just some of the areas that will characterise the company. These areas will also determine its evolution and future projects.

www.acciona-agua.com

Exhibitor Promotion

New WTW Mayflower in Plymouth set to open

South West Water is the first British utility using advanced treatment technology by PWNT.

This year, South West Water’s new Mayflower Water Treatment Works (WTW) in Plymouth, United Kingdom, will open its doors. The construction of this new £60 million state-of-the-art Water Treatment Works started in April 2016 after a 27-month pilot study. It will use cutting-edge treatment processes, designed and developed by Dutch advanced water technology provider, PWNT.

Established relationship

Prior to the development of the full-scale plant, South West Water and PWNT already possessed a strong relationship through intensive pilot studies and collaborations, with PWNT being global leaders in the development and application of advanced water treatment technologies utilizing ion exchange and ceramic membranes.

The new Mayflower Water Treatment Works will use SIX® (suspended ion exchange with resin regeneration system), ILCA® (inline coagulation and adsorption) and CeraMac® C-90 (ceramic membrane microfiltration). It is the first time that this combined technology will be used in the UK, with extensive pilot research taking place previously at a pilot facility from April 2013 until June 2015.

These new technologies are also needed to tackle the growing problem of increasing dissolved organic carbon (DOC) throughout northern Europe. For that reason, both companies are participating in the EU Interreg 2 Seas DOC2C’s project. The DOC2C’s project will cover a period of four years and started at the end of 2015. The main objective is to significantly improve and accelerate innovation in drinking water treatment with the focus on DOC removal through collaboration within the 2 Seas region (the Channel and North Sea).

The DOC2C’s consortium consists of PWNT (NL), South West Water (UK), De Watergroep (BE), Lille University (FR) and Delft University of Technology (NL). This project is funded by the European Union and co-financed by the Dutch Government, the Province of North Holland and the Province of West Flandres in Belgium.

Mayflower: high-quality drinking water supply

The Mayflower Water Treatment Works that will become operational this year will replace the outdated treatment works at Crownhill in Plymouth, which was built in the 1950s and is reaching the end of its useful life. Crownhill Works will retire from service a few months later, anticipated to be December 2018/January 2019.

The project is South West Water’s biggest single capital investment in its highly-rated 2015-20 business plan and around 150 people are employed during the construction of Mayflower Water Treatment Works. The plant will meet the needs of Plymouth’s growing population and provide a secure, high-quality drinking water supply for the wider Plymouth area for generations to come.

www.pwnt.com

Exhibitor Promotion

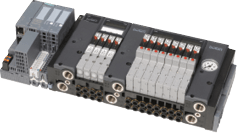

Valve islands for drinking and process water treatment

The valve islands AirLINE (Type 8652) and AirLINE SP (Type 8647) offer numerous adjustable monitoring and diagnostic functions, which improve system availability and process reliability, while at the same time enabling preventive maintenance.

Key information, e.g. the current switching statuses of the pilot and process valves or errors such as cable breaks, is shown to users directly via an integrated display. Valve islands communicate via a range of common field bus protocols, e.g. EtherNet/IP, PROFINET IO and PROFIBUS DP.

If a high level of network availability has to be ensured, the Media Redundancy Protocol from PROFINET IO can be used. An increased level of system availability is additionally guaranteed by up to 64 hot-swap capable valves per island which can be replaced during live operation without shutting down the system. As an additional safety function, check valves are used in the exhaust channel. They prevent the unwanted activation of valves by pressure peaks in the exhaust channel. All these functions ensure high process reliability.

Within the context of Industry 4.0, valve islands are increasingly becoming electro-pneumatic automation systems. Type 8647, which is fully integrated in the distributed I/O system SIMATIC ET 200SP from Siemens, is definitely setting the benchmark here. It enables fast and seamless integration both for initial start-up and subsequent monitoring of live operation. The executed switching cycles are, for instance, forwarded to the control system. This offers users the benefits of preventive and wear-optimised maintenance and less downtime.

www.burkert.com