Five Steps for Reversing Infrastructure Aging

by Chuck McCollum

The performance of our nation's sewer collection systems is deteriorating rapidly in many areas of the country, owing to a combination of aging infrastructure and changing operational conditions. Limited budgets and staff resources have forced many utilities to adopt a ‘find and fix as you go' approach to system maintenance. This reactive approach can patch up short-term problems, but does nothing to ensure the long-term health of a collection system and will lead to a higher operating cost with substantial risk of property and environmental damage.

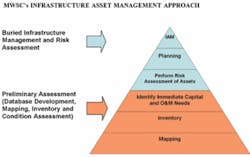

Five years ago the Marblehead Water and Sewer Commission (MWSC), which serves 20,000 residents, was facing rising insurance claims and repair costs related to system failures and sewer backups of its approximately 87 miles of sewer pipe. By adopting a five-step, systematic approach to Infrastructure Asset Management, or IAM, the town has not only eliminated these problems, but has actually improved both the condition of its assets and its allocation of resources and budget.

Step One: Map Buried Assets

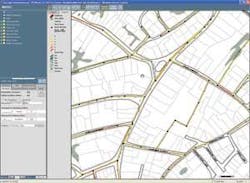

Map Buried Assets In 2003, recognizing the need to document the location and physical attributes of its buried assets, the MWSC hired a consultant to develop an electronic map of its collection system using Geographic Information System (GIS) technology. Existing as-built drawings and records were incorporated into the mapping project, which was completed in 2004. The town now had an electronic reference point and system to document not only the location but also the size, material, year installed and other attributes of its entire collection system.

Step Two: Perform Inventory of Assets

Once mapping was complete, the Water and Sewer Commission hired InfraMetrix LLC to perform an inventory update and structural conditions assessment on a pilot project that contained about 10 miles of pipe and 187 manholes.

Using truck-mounted zoom camera technology, InfraMetrix located and inspected each manhole and pipeline using Pipeline Assessment Certification Program (PACP) techniques. The physical attributes, maintenance requirements, and the condition of all the district's assets were evaluated. Once the condition assessment was completed, InfraMetrix corrected and expanded the GIS to include the zoom camera video inspections, defect photos, and the service and structural condition ratings as determined by their evaluation.

Having proven the value of capturing current inventory and condition assessment on the pilot, the MWSC initiated a second IAM and Risk Assessment project in October 2005.

This time, InfraMetrix's inspection data and observations were loaded into VUEWorks, an Asset Management software solution that provides the MWSC with the ability to query the inspections and videos attached to an asset directly from the GIS map. Updates to the sewer system inventory were automatically reflected in the VUEWorks software.

InfraMetrix inspected 351 manholes and 370 pipe segments in less than four weeks. The manhole inspections revealed that 52% of the inspected manholes had a potential for blockage and 18% were urgent. The service condition of pipelines was similar to the service condition of manholes: 15% of the inspected manholes required immediate attention, while 20% of the inspected manholes were found to need repairs. The pipelines were found to be in very good structural condition.

Step Three: Identify Immediate Capital Needs

Having successfully gone through Steps 1 and 2, the MWSC now had a prioritized list of cleaning and in-line inspection recommendations. Only 5% of the inspected pipelines required more detailed in-line CCTV inspection, providing a significant cost savings than if the Commission had elected to use a traditional in-line CCTV process. Instead, the MWSC could focus its resources in problem areas discovered during the screening process. The MWSC proceeded to clean the manholes and pipelines with immediate potential for blockage issues, which could lead to costly environmental clean-up and property damage settlements.

Step Four: Rank Assets

The next step towards IAM was to assess the probabilities and consequences of asset failure in order to prioritize repairs and capital spending. First, assets were assigned critical attribute data and the importance of each asset was weighted with a consequences-of-failure score based on its impact on the system. For example, a 70-year-old sewer pipe serving 15 households would be weighted less important than a 40-year-old pipe serving 100 households. In this way, MWSC was able to forecast the probability of service and structural failure, calculating risk as the product of the consequence and the probability of failure for each asset. The outcome of this step was a prioritized list of maintenance and capital improvements.

The MWSC is currently using the condition information to determine the probability of failure and to calculate risk to prioritize future action. The consequence of failure to public health, environment, property, costs, and community are also being configured in the asset management software. By using these methodologies to prioritize maintenance and capital expenditures, the MWSC will maximize the resources expended in the near term. As money is invested into the collection system the risks will be reduced, the overall utility condition index (UCI) will increase and less money will be spent on reactive maintenance and insurance claims.

In the future, the MWSC will use its asset management software to manage the new condition assessment data and prepare maintenance management and capital improvement master plans.

The software also provides many features to streamline the process of viewing and collecting the information required for cost-effective operations. MWSC staff members can now quickly capture calls from customers and produce detailed monthly reports on call activity. Service calls can then be used with inspection data to develop work orders. Work activity is captured in VUEWorks, where reports can be generated to reflect how the work improves the overall condition of the system.

Step Five: Utilize Knowledge for Planning

The ultimate goal of an IAM process is to eliminate system failures by proactively planning and budgeting maintenance activities. In this final planning step, maintenance activities are based on the probabilities and consequence of backups and overflows. Capital improvements are scheduled considering multi-year budget forecasting, how different budget scenarios affect the overall condition of the sewer system and the overall capital needs of pipelines, structures, treatment and pumping facilities. The outcome of this task is an annual budget for maintenance and capital improvements.

MWSC was concerned that the first four steps of the IAM program would be too costly if a traditional approach to collection system management was used. Through the pilot programs, the MWSC discovered that with new inspection technologies and GIS-enabled asset management software applications, they could focus their limited funding and increase productivity, completing the first four steps of the program at a fraction of the cost and time.

The MWSC has also facilitated its long-term planning by creating multi-year simulations to determine the impact of future investments on the Utility Condition Index, so that enough money is allocated at the right times. This type of planning allows the utility to adjust rates over a longer period of time and demonstrate to its customers why rates need to be adjusted. This is an important factor as most utilities are challenged with making capital investments in their aging infrastructure to maintain an acceptable level of service to their customers.

MWSC has implemented 70% of its sanitary sewer system into the IAM program and plans to implement the remainder of the system within the next two years.

About the Author:

Chuck McCollum is the Assistant Superintendent for the Marblehead Water & Sewer Commission (Marblehead, MA).