Keeping Your Valve Box Secure

The gate valve is one of the most critical and expensive components of a water distribution system. Interestingly, it’s accessed by one of the least expensive assets, the valve box. If you are unable to exercise the valve, it is of no use. The costs to reset a valve box often involve thousands of dollars and the possible issues of traffic control, rerouting water, and increased manpower.

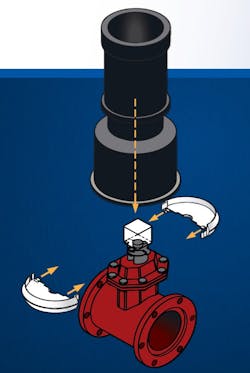

A BOXLOK prevents the common issue of valve box shift. When valve boxes are set, there is nothing to prevent the weight of the back fill from pushing the valve box against the operating nut of the gate valve. The valve box must be handled after the backfill is added and during compaction to maintain the position over the operating nut.

By introducing the Boxlok between these two components, one can maintain the position of the valve box around the operating nut. The valve can be exercised, prolonging its life and reducing the need to reset valve boxes, eliminating the costs involved.

The Boxlok is made from high-density plastic, the same material used to make milk crates. This material is designed to withstand the elements and last longer than the valve itself. The Boxlok’s white color, makes it easier to see the operating nut from the top of the valve box at surface level. The patented two-part design allows the operator to snap the Boxlok around the stem, below the operating nut, without removing any portion of the valve components. The Boxlok is also a non-load-bearing device, so the valve and valve box are not connected, ensuring no force transferred from the surface damages the valve underground. WW

Over the last 15 years, more than 100,000 Boxloks have been installed around the US, keeping valves operable and saving municipal teams’ the hassle of resetting valve boxes. Learn more at https://boxlok.com.