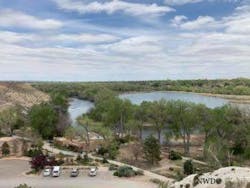

The City of Pueblo, Colo., is located at the confluence of the Arkansas River and Fountain Creek, 112 miles south of Denver, Colorado. With a population of over 160,000 people in its metropolitan statistical area, it ranks ninth among Colorado cities.

The Nature & Wildlife Discovery Center, located in Rock Canyon along the banks of the Arkansas River provides unique experiences in education, conservation, and recreation in environmental stewardship. In 2016, the Raptor Center admitted 372 raptors and released 100 back into the wild.

To collect wastewater from the park and park restaurant, then lift the wastewater to be processed, a wet well (lift station) at the Raptor Center contains two digester pumps (lead and lag pumps) to maintain levels in the wet well from 2.2 feet to 3.2 feet. The wet well dimensions are approximately 8 feet in diameter and 10.5 feet deep. There are three pipes that drain into the wet well from the park’s facilities. Since the site is designed to run autonomously, a back-up mechanical float system would send an alarm to the office if alarm levels were detected.

The previous controller used a problematic bubbler system (differential pressure) for level feedback to control the pumps and to maintain programed levels. For accurate level measurement, a Laser Technology TruSense S330 laser sensor was installed to replace the bubbler system. The new system was designed to include integration into existing standalone controllers, compile sensor data collection for later evaluation, and consider the environment.

Critical Set Points

The laser sensor allows the wet well to fill to a predefined height and then lifts the wastewater from the wet well to be processed. To prevent the pump(s) from running dry, when the liquid gets down to a predefined level, the pump(s) should turn off. During normal pump-down operations only one pump (the lead pump) is required. The second pump (the lag pump) is used during high demand effluence filling.

If the system moves out of bounds of the control levels for any reason, there are over and under alarm points. Once a critical alarm level been detected, the cellular system will alert that a critical level has been met.

Integration Considerations

To integrate the TruSense S330 into the system, a bracket was made for mounting the sensor in the wet well on an existing angle iron support. The shielded cable that comes with the S330 was used to connect the sensor to the control panel via an existing pipe leading from the wet well into the control panel.

Setup in System

Setup was made quick and easy using the 4–20 mA setup software provided by Laser Technology.

The next step was to reprogram the previous pump controller to use the 4–20 mA loop input to replace the bubbler system input. After the sensor and controller were configured, a data collector was attached to capture the RS-232 measurement data for later evaluation.

The final step, after verification of the system operation, was to allow the pump controller control of the system. The system has been currently running since March 5, 2019, and has continued to run without any alarms or failures.

Inflow into the wet well is controlled by park usage and outflow (pump-down) is controlled by the lead/lag pump volume. Since the difference of inflow is much less then outflow, the outflow time does not noticeably vary from pump-down cycle to pump-down cycle.During setup, the 4–20 mA loop update was set to a 30-second update interval per the customer request.

During a pump-down, a 30-second delay can equate up to a 0.2-foot variance in levels before the pump turn-off. Graph 1 shows the repeatability of the pump down cycle for one week.

Environmental Operation

The sensor was installed about six inches under an aluminum lid covering the wet well. It is exposed to Hydrogen Sulfide (H2S) gas which is very corrosive.

During testing, the sensor was exposed to temperatures ranging from about 32°F to 105°F. This is based on the open-air temperatures during the testing period.

After continued operation from March to August, the sensor showed no signs of corrosion and continues to function.

Summary

Installation at the Nature & Wildlife Discovery Center has proven the S330 is a very capable non-contact level sensor in an enclosed environment. The best advantages the sensor has are ease of setup, ease of maintenance with minimal downtime, and the ability to work in corrosive liquid environments.

In the wastewater industry, the S330 would integrate well since it is non-contact and not subject to failure in contaminated water like bubbler systems or pressure sensors. The sensor also proved to be very repeatable over time.

Leveraging the 4–20 mA loop, the S330 can directly replace aging unreliable measurement systems currently using the 4–20 mA communication loop. WW

About the Author: John Budden is a sensor field application engineer with Laser Technology Inc.

About the Author

John Budden

John Budden is a sensor field application engineer with Laser Technology Inc.