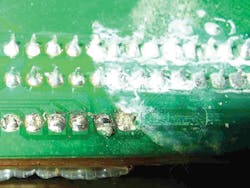

Connections appear clean (even after using generic contact cleaners or alcohol) but corrosion you can’t see remains at the microscopic level.

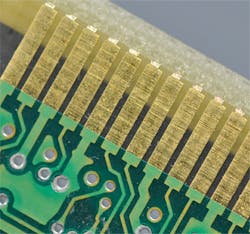

DeoxIT can be applied wherever you are experiencing signal degradation. This includes edge connectors, DIMM sockets, A/V and RF connections, transducers, flow meters, or door switches. Taking this simple step will eliminate oxidation/corrosion, increase/restore connectivity, and extend equipment life.

Several treatment facilities are already using DeoxIT with excellent results. One municipal treatment facility engineer noted that, after using the cleaner, it was the first time in his many years that all green lights appeared on his SCADA board. WW

CAIG Laboratories offers an extensive array of cleaners, lubricants, enhancers, preservatives and accessories for electronic, electrical and mechanical applications. CAIG’s DeoxIT® Products are environmentally safe and CAIG is constantly developing new products and applicators. Learn more at caig.com.

Circle No. 309 on Reader Service Card